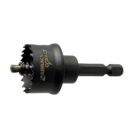

Cobalt Sheet Steel Hole Saw with Spring | Fast, Clean Cutting in Sheet Metal

- Optimised for sheet steel – engineered to cut thin mild steel, galvanised steel and coated sheet cleanly, with minimal burring.

- Cobalt cutting edge – improved heat and wear resistance compared with standard HSS hole saws, for a longer working life in metal.

- Built-in ejector spring – automatically pushes the slug out of the cutter, reducing downtime between cuts.

- Precise, round holes – ideal for cable glands, conduits, pipe entries, switches and sockets in steel panels and trunking.

- Compatible with standard drills – fits a suitable arbour/mandrel for use with most corded and cordless drills in rotary mode.

Free shipping on orders over £60

- No-Risk Money Back Guarantee!

- No Hassle Refunds

- Secure Payments

Cobalt Sheet Steel Hole Saw with Spring – Clean, Fast Cutting in Sheet Metal

Cobalt Sheet Steel Hole Saw with Spring is a professional-grade metal hole cutter designed specifically for clean, accurate holes in sheet steel and other thin metals. Featuring a durable cobalt-alloy cutting edge and an integrated ejector spring, it delivers fast cutting performance while automatically pushing out the slug – ideal for electricians, plumbers, HVAC installers and fabricators working on enclosures, trunking, panels and ducts.

The Cobalt Sheet Steel Hole Saw with Spring is purpose-designed for trades who regularly need to create neat, accurately sized holes in sheet metal. Unlike general-purpose hole saws, this cutter uses a cobalt-alloy tooth form optimised for thin steel, offering improved hardness and heat resistance for prolonged service life in demanding conditions.

The hole saw forms part of a two-piece system: the saw body itself and a compatible arbour (mandrel) with a pilot drill. Once assembled, it can be used in a standard three-jaw chuck drill or suitable cordless combi drill set to rotary-only. The fine, hardened teeth are designed to give a smooth cutting action in sheet metals, reducing grabbing and distortion of the workpiece.

A key advantage of this model is the integrated ejector spring fitted behind the hole saw body. As you complete each cut, the spring pushes the slug (cut-out disc) forwards, making it far easier and faster to clear the waste piece from the cutter. This is particularly useful when cutting multiple holes in distribution boards, metal trunking, control panels, consumer units and junction boxes, where productivity matters.

When used with appropriate cutting speeds and cutting lubricant, the cobalt hole saw is suitable for a range of thin metals including mild steel sheet, galvanised steel, coated sheet metal and some stainless steels (within the manufacturer’s recommended thickness). It can also be used on non-ferrous metals such as aluminium and some plastics, making it a versatile addition to any installation kit.

These hole saws are manufactured to consistent tolerances to produce accurately sized holes compatible with popular sizes of cable glands, knock-out replacements, conduit fittings and pipe entries. For project-critical cut-outs (e.g. IP-rated enclosures, electrical panels complying with BS EN standards), always refer to the specific size requirements of the fittings being installed.

Typical Use Cases

- Cutting holes in metal consumer units, distribution boards and control panels for cable glands and conduits.

- Creating entries in steel trunking and cable tray lids for wiring routes.

- Forming neat openings in plasterboard-backed metal studs and metal-faced partitions for services.

- Cutting pipe and sensor entry holes in HVAC ducting, fan casings and sheet metal housings.

- General fabrication tasks on steel cabinets, boxes and enclosures where a clean, round aperture is required.

Drilling & Best Practice Tips

- Choose correct size: Match the hole saw diameter to the fitting or gland size specified (e.g. 20 mm, 25 mm, 32 mm etc). Check manufacturer datasheets for the exact hole size required.

- Use the right drill: Fit the hole saw to a suitable arbour and mount in a drill with variable speed and rotary-only mode. Avoid impact or hammer settings.

- Clamp the workpiece: Secure sheet metal firmly using clamps or a vice to prevent spinning or vibration. Support thin sheet from behind where possible.

- Mark the centre: Mark the centre point accurately using a centre punch to help guide the pilot drill and reduce wandering.

- Correct speed & lubricant: Run at a moderate speed suitable for metal cutting (slower than for wood). Use an appropriate cutting oil or lubricant to reduce heat and extend tool life.

- Apply steady pressure: Let the teeth cut at their own rate. Do not force the saw; excessive pressure generates heat and shortens life.

- Allow spring to eject slug: After breaking through, stop the drill and let the ejector spring push out the slug. Remove any remaining waste carefully with pliers if needed.

- Deburr edges: Lightly deburr the cut edge with a file or deburring tool, especially on live electrical enclosures, to remove sharp edges.

Always wear suitable PPE – safety glasses, gloves, hearing protection and appropriate clothing. Follow your drill manufacturer’s safety instructions and any relevant site method statements. When working on live or potentially live electrical enclosures, comply with BS 7671 and safe isolation procedures.

Cobalt Sheet Steel Hole Saw with Spring Features

- Cobalt-alloy cutting teeth – enhanced heat and wear resistance for longer life in sheet steel compared with standard HSS hole saws.

- Integrated ejector spring – built-in spring behind the saw body for automatic slug ejection and faster repeat cuts.

- Precision ground tooth form – designed to give clean, accurate holes in thin metals with reduced grabbing.

- Standard arbour fitment – compatible with common hole saw arbours/mandrels for use in three-jaw chuck drills.

- Accurate sizing – manufactured to tight dimensional tolerances to match common gland, conduit and fitting sizes.

- Versatile material compatibility – suitable for mild steel sheet, galvanised steel and some stainless / non-ferrous metals within recommended thickness.

- Trade-quality construction – robust design for daily use by electricians, plumbers and fabricators.

Cobalt Sheet Steel Hole Saw with Spring Technical Information

- Product type: Cobalt sheet steel hole saw with integrated ejector spring.

- Material: High-speed steel with cobalt-alloy cutting edge (exact grade per manufacturer specification).

- Application: Cutting round holes in sheet steel and thin metal using a suitable arbour and rotary drill.

- Suitable materials: Mild steel sheet, galvanised steel, coated sheet, some stainless and aluminium (within recommended thickness – refer to manufacturer data).

- Recommended thickness: Typically for sheet material up to a few mm thick; check the technical data sheet for maximum thickness per diameter and material.

- Tool compatibility: Use with a suitable hole saw arbour in corded or cordless drills (rotary-only, variable speed).

- Standards & quality: Manufactured under controlled quality procedures; for any specific EN / ISO test data or performance standards (e.g. for electrical enclosures to BS EN 61439), refer to the manufacturer’s technical documentation.

- Best practice: Use with cutting lubricant, controlled speed and proper clamping to align with good metalworking practice and tool life expectations.

For safety- and performance-critical applications (e.g. cutting apertures in certified electrical enclosures or panels), always ensure hole diameters and edge quality meet the relevant product standards and manufacturer installation instructions.

Frequently Asked Questions – Cobalt Sheet Steel Hole Saw with Spring

1. What is the advantage of a cobalt sheet steel hole saw over a standard HSS hole saw?

Cobalt hole saws are specifically designed to handle higher cutting temperatures and more abrasive materials. The cobalt-alloy teeth stay sharper for longer when cutting sheet steel, giving better tool life and consistent performance compared with standard HSS-only cutters, especially in repeated use on metal.

2. What thickness of steel can this hole saw cut?

The cutter is optimised for sheet materials rather than heavy plate. Typical use is in thin mild steel and galvanised sheet used for enclosures, trunking and panels. Exact maximum thickness depends on the diameter and material; always check the manufacturer’s technical data sheet for recommended thickness limits for mild steel and stainless steel.

3. Do I need to use cutting oil with this hole saw?

Yes, it is strongly recommended. Using a suitable cutting oil or lubricant on metal significantly reduces heat build-up, improves surface finish and extends the life of both the cobalt teeth and the arbour. For plastics, lubricants are usually not required (and some oils can attack certain plastics – check compatibility).

4. Can I use this hole saw in a cordless drill?

Yes, provided your cordless drill has sufficient torque and variable speed control, and you use it in drill (rotary-only) mode. For larger diameters in steel, a more powerful corded drill or low-speed, high-torque cordless model is recommended. Always keep a firm grip on the tool and ensure the workpiece is securely clamped.

5. What does the spring on the hole saw actually do?

The integrated ejector spring sits behind the hole saw body. As you finish the cut and break through the material, the spring pushes the slug (cut-out piece) forward and out of the cutter. This saves time compared with standard hole saws, where you often have to lever the slug out manually with a screwdriver after each cut.

Cobalt Sheet Steel Hole Saw with Spring Common Uses / How to Use

Common Uses

- Installing cable glands and conduits in metal distribution boards and panels.

- Cutting entry holes in steel trunking, steel cabinets and metal-clad switchgear.

- Fabricating apertures in HVAC ductwork and metal housings for pipework and sensors.

- Preparing control panel fronts for switches, push-buttons and indicator lamps (where sizes suit).

- General metalworking and site fabrication tasks needing clean, accurately sized holes in sheet metal.

How to Use – Step-by-Step Summary

- Select size & arbour: Choose the correct diameter hole saw and fit it to a compatible arbour with pilot drill.

- Insert the arbour shank into your drill’s chuck and tighten securely.

- Prepare the workpiece: Mark the hole centre, centre-punch if possible, and clamp the sheet securely.

- Apply lubricant: Add a few drops of suitable cutting oil to the cutting area when working on metal.

- Drill at moderate speed: Start at a low speed to establish the cut, then continue at a controlled, moderate speed with steady pressure.

- Complete the cut: As you break through, maintain control and then stop the drill, allowing the spring to eject the slug.

- Deburr & finish: Remove any sharp edges and clean the surface before fitting glands, conduits or other accessories.

| Size | 16mm, 19mm, 20mm, 22mm, 25mm, 29mm, 30mm, 32mm, 35mm, 38mm, 2 Piece Set 20mm, 25mm, 3 Piece Set 20mm, 25mm, 32mm |

|---|

Shipping Policy

At Always First 4 Fixings, we know that your projects rely on fast, dependable delivery. That’s why we offer flexible UK shipping options designed for tradespeople and businesses:

Fast Dispatch: Orders are processed and dispatched within 24 hours on working days.

Free shipping on all orders over £60 (UK mainland).

Express options available to keep your jobs moving.

Click & Collect: Order online and pick up at your convenience (if applicable).

Reliable Couriers: We use trusted UK carriers to ensure your fixings and fasteners arrive on time.

You’ll receive tracking details as soon as your order leaves our warehouse. Delivery times may vary depending on location and availability, but we work hard to get your order to you as quickly as possible.

At Always First 4 Fixings, we know that your projects rely on fast, dependable delivery. That’s why we offer flexible UK shipping options designed for tradespeople and businesses:

Fast Dispatch: Orders are processed and dispatched within 24 hours on working days.

Free shipping on all orders over £60 (UK mainland).

Express options available to keep your jobs moving.

Click & Collect: Order online and pick up at your convenience (if applicable).

Reliable Couriers: We use trusted UK carriers to ensure your fixings and fasteners arrive on time.

You’ll receive tracking details as soon as your order leaves our warehouse. Delivery times may vary depending on location and availability, but we work hard to get your order to you as quickly as possible.