Many DIY enthusiasts and professionals alike will benefit from understanding concrete masonry screws as they continue to evolve in 2025. In this guide, you’ll discover important information on selecting, installing, and utilising these fasteners effectively, ensuring your projects are both safe and durable. You’ll also learn about the latest advancements and best practices to enhance your construction skills. Armed with this knowledge, your next job will not only be simpler but also more efficient and reliable.

Key Takeaways:

- Concrete masonry screws provide a reliable fastening solution, combining ease of installation with strong holding power, making them vital for various construction projects in 2025.

- Innovations in materials and coatings enhance the durability and corrosion resistance of these screws, ensuring long-lasting performance in diverse environmental conditions.

- Understanding the correct sizing and installation techniques is vital for optimising their performance and preventing damage to masonry substrates.

The Unseen Forces Driving Demand for Concrete Masonry Screws

The Unseen Forces Driving Demand for Concrete Masonry Screws

The surging demand for concrete masonry screws is driven by numerous unseen forces, encompassing economic trends, sustainability concerns, and ongoing advancements in construction techniques. As industries evolve, your need for reliable and efficient fastening solutions becomes more pronounced, making understanding these underlying factors imperative for making informed decisions.

Economic Trends Influencing Construction Costs

Current economic conditions significantly impact construction costs, affecting your choices for materials and fastenings. Increasing labour and raw material prices have led many contractors to seek solutions that reduce overall expenses without compromising quality. Reports indicate that a projected increase of up to 10% in construction costs this year has accelerated the shift towards reliable and cost-effective fastening methods, such as concrete masonry screws.

Shifts in Consumer Preferences Towards Sustainable Materials

An increasing preference for sustainable building materials influences the choices you make for your projects. With growing awareness around environmental impact, you are more likely to seek out products that not only meet safety standards but also align with ecological values. The push for eco-friendly practices within the construction industry is compelling manufacturers to innovate. For instance, many concrete masonry screws are now manufactured with recycled materials, helping you to achieve sustainability goals while maintaining structural integrity. This movement reflects a broader trend where consumers prioritise environmentally conscious alternatives, promoting greater responsibility in material selection.

Innovations Reshaping the Future of Concrete Fastening

As the construction industry evolves, innovations in concrete fastening are paving the way for enhanced performance and efficiency. New materials, cutting-edge designs, and advancements in technology are transforming how you approach concrete masonry screws. From increased tensile strength to sustainability-driven manufacturing processes, these innovations are set to redefine best practices, ensuring you achieve optimal results in your projects.

Advances in Material Science and Screw Design

Recent breakthroughs in material science have led to the development of screws that offer enhanced durability and resistance to corrosion. You’ll find screws crafted from advanced alloys that not only improve load-bearing capacity but also reduce wear over time. Innovative thread designs are also emerging, optimising grip in various substrates, providing you with options that are tailored for specific applications.

The Integration of Smart Technology in Construction

Embracing smart technology is revolutionising the way concrete fastening is approached. Smart screws equipped with sensors can provide real-time data on tension and structural integrity, allowing you to monitor fastening performance remotely. This technology minimises the risk of failure by alerting you to any potential issues before they become critical, thus improving overall safety and efficiency on your site.

The integration of smart technology not only streamlines workflows but also enhances collaboration among team members. For instance, construction teams can use mobile applications to access data from smart screws, allowing you to make informed decisions swiftly. Predictive maintenance becomes possible, with analytics predicting when a screw might need attention, thereby reducing downtime and settling disputes with data-driven evidence. As you embrace these advancements, you will find that installations become not just easier but significantly safer and more efficient.

Optimal Practices for Selection and Application

Optimal Practices for Selection and Application

Your choice of concrete masonry screws can significantly impact the success and durability of your project. Ensuring you select the right screw involves considering several factors, including the type of material being fastened, the load requirements, and environmental conditions. Proper preparation and installation techniques are equally important to guarantee a strong and long-lasting bond.

Key Factors for Choosing the Right Concrete Masonry Screw

When opting for concrete masonry screws, consider the following key factors:

- Material compatibility: Match the screw to the masonry material.

- Load capacity: Ensure the screw can handle the intended weight.

- Coating type: Select corrosion-resistant options for outdoor use.

- Length and diameter: These should correspond to your specific application.

Any incorrect choice can lead to failure in the fastening, which may compromise your project’s integrity.

Step-by-Step Guide to Installation for Maximum Durability

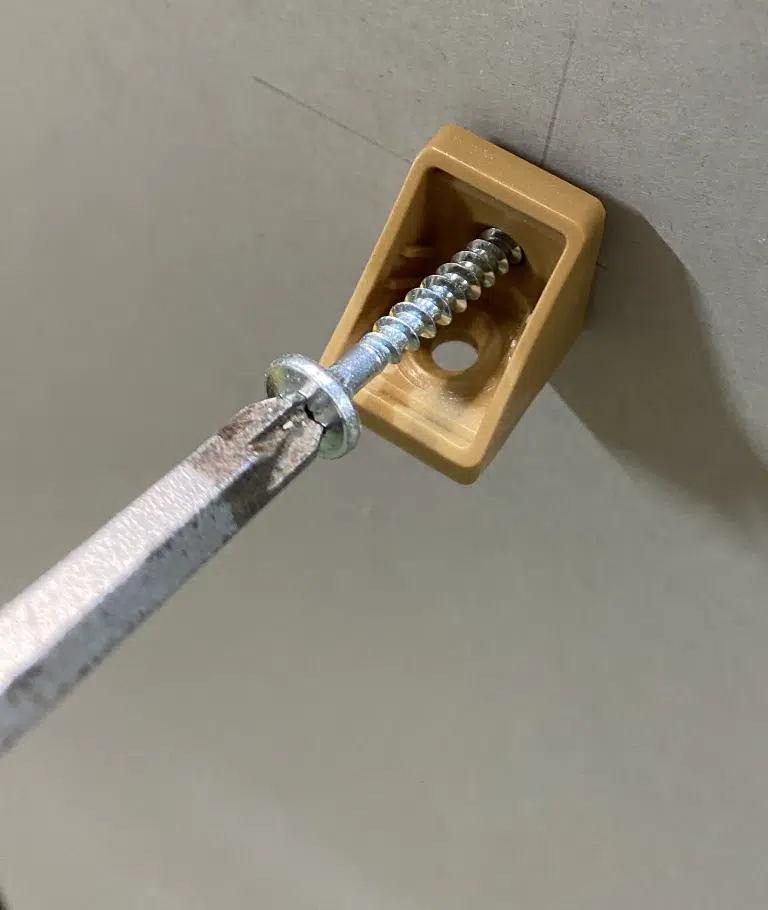

For optimal results during installation, follow this detailed step-by-step guide:

| Step | Description |

|---|---|

| 1 | Select suitable masonry screws based on your project needs. |

| 2 | Drill holes into the masonry using the correct-sized bit. |

| 3 | Clean out any dust or debris from the holes. |

| 4 | Insert the screw and drive it into the hole at the recommended torque. |

Following the installation steps meticulously ensures a solid connection and enhances overall durability. Each phase plays a vital role in the process: using a suitable drill bit ensures correct hole size, while cleaning the holes prevents debris from affecting the grip. Maintaining the proper torque during installation also plays a significant role in keeping the screws in place, thereby reducing the risk of loosening over time.

| Tips for Enhanced Durability | Details |

|---|---|

| Use a torque wrench | This prevents over-tightening and potential damage to the screw. |

| Ensure proper alignment | Incorrect angles can compromise holding strength. |

| Consider environmental factors | Certain coatings may be necessary for moisture-prone areas. |

| Routine inspections | Check periodically for any signs of wear or loosening. |

Navigating Challenges: Common Pitfalls and Solutions

Common pitfalls can hinder your success with concrete masonry screws. From incorrect drilling depths to choosing the wrong screw size, these oversights can lead to structural failures. Understanding these challenges and applying the appropriate solutions will ensure your projects are efficient and durable, boosting your confidence as you work.

Identifying and Avoiding Installation Errors

Installation errors often stem from miscalculating the depth of the drill hole or not adequately clearing debris. Consistently checking your measurements and ensuring a clean hole can prevent these mistakes. Employing a depth gauge can also enhance your precision and promote better anchorage for your screws.

Addressing Environmental Challenges in Different Climates

Addressing Environmental Challenges in Different Climates

Environmental factors like moisture, temperature extremes, and salt exposure can significantly impact the performance of concrete masonry screws. In humid or salty conditions, opt for corrosion-resistant screws to enhance longevity. Conversely, consider thermal expansion in regions with temperature fluctuations, ensuring that your installation can flex without compromising integrity.

Different climates pose unique challenges that you must address for successful applications of concrete masonry screws. For example, in coastal areas, the saline environment can lead to rapid corrosion, making stainless steel screws a wise choice. In colder climates, the freeze-thaw cycle may cause expansion and contraction, requiring you to use longer screws or special adhesives to accommodate movement. Assessing these environmental factors beforehand will save you time and money while ensuring the durability of your installations.

The Competitive Landscape: Major Players and Market Dynamics

In 2025, the market for concrete masonry screws is increasingly competitive, with key players like Hilti, Simpson Strong-Tie, and ITW Construction Products dominating the landscape. These companies leverage advanced technology to enhance product durability and user-friendliness, ensuring they meet the evolving needs of professionals in the construction industry. Market dynamics have shifted towards sustainability, pushing firms to innovate while adhering to eco-friendly practices and materials, ultimately driving growth and attracting a more environmentally conscious customer base.

Trends in Brand Innovations and Product Offerings

Brand innovations focus on incorporating advanced materials and eco-friendly options into concrete masonry screws, catering to the growing demand for sustainability. Manufacturers are expanding their product lines with specialised screws designed for specific applications, such as faster installation and enhanced corrosion resistance. Such innovations help differentiate brands in a crowded market, ensuring you have a variety of choices that meet project requirements effectively.

The Role of Regulations and Standards in the Industry

Government regulations and industry standards play a significant role in shaping the concrete masonry screw market, ensuring products meet safety and performance guidelines. Compliance with standards such as ASTM (American Society for Testing and Materials) ensures that the screws you select will perform reliably under various conditions, reducing the risk of failure and accidents. Manufacturers must continually adapt their products to meet these evolving regulations, fostering a culture of innovation while maintaining safety and quality in construction practices.

Specific regulations, such as those set by the International Code Council (ICC), provide clear guidelines on materials and structural integrity, influencing both design and usage. As building codes become more stringent, you’ll find that adherence to these standards not only enhances your project’s safety but also increases its overall value. Consequently, manufacturers actively work with governing bodies to ensure their products are compliant, often leading to enhancements in ease of installation and longevity, which directly benefit you as the end user.

Summing up

Conclusively, as you research into the ultimate guide to concrete masonry screws in 2025, you will find that understanding the various types, applications, and installation techniques can greatly enhance your building projects. By equipping yourself with this knowledge, you will not only ensure greater efficiency but also improve the overall quality and durability of your work. Embrace these insights, and you’ll be well-prepared to tackle any masonry task with confidence.

FAQ

Q: What are concrete masonry screws and how do they differ from other types of screws?

A: Concrete masonry screws are specifically designed for fastening materials to concrete or masonry surfaces. Unlike standard screws, which may shear or bend when driven into hard surfaces, concrete masonry screws feature a unique thread design that enables them to cut into the concrete as they are driven in. This design allows for a secure hold, making them ideal for construction and renovation projects involving concrete blocks, bricks, and other masonry materials.

Q: What materials are best suited for use with concrete masonry screws?

A: Concrete masonry screws are compatible with a variety of materials, including wood, metal, and certain types of plastic. When fastening wood to concrete, it is advisable to use a washer to distribute the load evenly. For metal applications, ensure that the screws you select are rated for that specific use to prevent corrosion or failure. If working with additional types of masonry or harder materials, consult the manufacturer’s specifications for optimal use.

Q: How do I determine the right length and diameter of concrete masonry screws for my project?

A: The length and diameter of concrete masonry screws you should use depend on the thickness of the material you are fastening and the load requirements. A general rule is to select a screw that penetrates the concrete by at least 1 inch for maximum hold. The diameter of the screw should also correspond to the load it is intended to support; heavier loads typically require thicker screws. Always consult a professional or refer to guidelines to ensure you choose the appropriate size for your applications.

Q: What tools are needed for installing concrete masonry screws?

A: To install concrete masonry screws, you will need a power drill with a hammer function or a rotary hammer, as these are effective for drilling into tough materials. Additionally, a masonry bit matching the screw diameter is required to create a pilot hole. Having a torque wrench can also be beneficial to ensure the screws are tightened to the right specifications, preventing over-tightening which might lead to cracking.

Q: Are there any specific safety precautions to take when using concrete masonry screws?

A: Yes, certain safety measures should be adhered to when using concrete masonry screws. It is important to wear appropriate personal protective equipment such as safety goggles, gloves, and a dust mask to protect against debris and particulate matter that may arise during drilling. Also, ensure your workspace is well-ventilated, and be mindful of any electrical wiring or plumbing that may be hidden within walls or concrete before drilling. Always inspect tools for damage before use to ensure they operate safely and effectively.

The Unseen Forces Driving Demand for Concrete Masonry Screws

The Unseen Forces Driving Demand for Concrete Masonry Screws Optimal Practices for Selection and Application

Optimal Practices for Selection and Application Addressing Environmental Challenges in Different Climates

Addressing Environmental Challenges in Different Climates