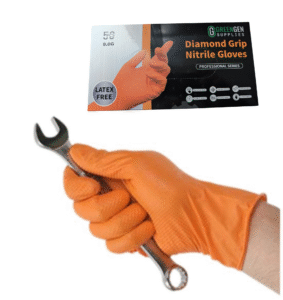

Most professionals overlook the significance of glove thickness, yet it can greatly impact your safety and efficiency. With 9.0G Diamond Grip nitrile gloves, you experience a perfect balance of dexterity and protection, delivering exceptional tactile sensitivity while safeguarding your hands from chemicals and punctures. Choosing the right thickness ensures your gloves provide the necessary barrier without compromising comfort, making them an ideal choice for a variety of tasks. Understanding these benefits can enhance your performance in demanding environments.

Key Takeaways:

- 9.0G thickness provides enhanced tactile sensitivity, allowing for precise handling and control.

- The durability of 9.0G Diamond Grip nitrile gloves reduces the risk of tears and punctures, ensuring prolonged use.

- Improved grip in wet or oily conditions enhances safety and reduces the likelihood of accidents during tasks.

Understanding Nitrile Gloves

Understanding Nitrile Gloves

Nitrile gloves are synthetic rubber gloves that provide excellent resistance to punctures, chemicals, and abrasion. They are widely used across various industries, including healthcare, automotive, and food services, due to their superior durability compared to latex or vinyl gloves. Their latex-free composition makes them a safe choice for individuals with sensitivities or allergies, ensuring broader usability in professional settings.

Composition and Features

Made from a copolymer of acrylonitrile and butadiene, nitrile gloves boast a flexible yet strong composition. They combine the elasticity of rubber with the chemical resistance of plastic, making them ideal for both delicate tasks and heavy-duty applications. These gloves often feature textured surfaces that enhance grip, specifically in wet or oily conditions, further improving functionality.

Comparison with Other Materials

Nitrile gloves stand out when compared to latex and vinyl counterparts. While latex gloves offer high elasticity, they pose allergy risks for some users. Vinyl gloves, on the other hand, are less durable and prone to tearing. Nitrile, with its balanced properties, provides an advantageous combination of strength, comfort, and safety, making them the preferred choice for professionals.

Comparison of Glove Materials

| Material | Advantages |

| Latex | High flexibility and comfort; economical |

| Vinyl | Cost-effective; easy to don |

| Nitrile | Durable; chemical resistance; no allergy risks |

Additional to their unique properties, nitrile gloves boast greater puncture resistance compared to both latex and vinyl. This characteristic is especially beneficial in medical and industrial environments where sharp objects are prevalent. For example, studies show that nitrile gloves decrease the likelihood of material failure, providing you with enhanced protection during demanding tasks. In a head-to-head scenario for tear resistance, nitrile gloves outperform vinyl by a significant margin, reassuring you of their reliability under pressure.

Performance Metrics of Nitrile Gloves

| Metric | Nitrile |

| Puncture Resistance | Superior, 2-3 times more than Latex |

| Tear Resistance | High; lasts longer in rigorous conditions |

| Chemical Resistance | Excellent; protects from a wider range of substances |

Importance of Thickness

Importance of Thickness

Your choice of glove thickness plays a vital role in both functionality and performance. Thicker gloves, like the 9.0G Diamond Grip nitrile options, offer a balance between dexterity and protection, ensuring you can complete tasks without compromising safety. This thickness enhances your experience, whether you’re handling chemicals, sharp objects, or delicate items, ultimately allowing for a more confident and effective workflow.

Impact on Durability

Protection Levels

The protection levels provided by thicker gloves cannot be overstated. With 9.0G Diamond Grip nitrile gloves, your hands are safeguarded against punctures, abrasions, and chemical exposure more effectively than with thinner gloves. The heightened thickness acts as a barrier, ensuring that you have the confidence to tackle tough tasks without risk of injury.

For instance, in industrial settings where sharp materials are common, the 9.0G Diamond Grip nitrile gloves can endure punctures that would easily compromise thinner options. You’ll find that the gloves not only protect from cuts, but also resist chemical degradation, allowing you to handle various substances with minimal risk to your skin. This level of protection is imperative for maintaining safety standards and ensuring peace of mind during demanding tasks.

Benefits of 9.0G Thickness

The 9.0G thickness of Diamond Grip nitrile gloves delivers a unique blend of strength and flexibility, catering to various demanding tasks across industries. The incredibly thin yet durable structure ensures you can work confidently without compromising on protection. The innovative design also allows for an increased range of motion, making these gloves ideal for intricate procedures where every action counts. Overall, 9.0G thickness equips you to perform reliably in diverse environments, ensuring safety and efficiency.

Sensitivity and Dexterity

When you wear 9.0G thickness gloves, you’ll immediately notice the exceptional tactile sensitivity they offer. This design allows you to feel textures and small details, which is vital for tasks requiring high precision. Whether you’re handling delicate instruments or assembling intricate components, the gloves enable you to maintain control and achieve accurate results without hesitation.

Resistance to Punctures and Tears

Resistance to Punctures and Tears

9.0G Diamond Grip nitrile gloves are engineered to resist punctures and tears effectively, providing a robust barrier against sharp objects. This superior durability allows you to confidently handle materials in high-risk settings without the fear of glove failure. Moreover, the gloves have been tested against various sharp items, ensuring that you can engage in your work without compromising safety.

The resistance to punctures and tears is particularly beneficial in professions such as healthcare, food handling, and manufacturing, where contact with sharp tools or materials is commonplace. You can rely on 9.0G gloves to protect your hands and maintain your focus on the task at hand. With a tensile strength that exceeds standard nitrile gloves, you can confidently navigate challenging environments, knowing that your protection is paramount. Field tests show that these gloves outperform competitors, leading to fewer incidents of glove-related breaches.

Practical Applications

9.0G Diamond Grip nitrile gloves excel in a myriad of practical applications, ensuring optimal performance across diverse environments. Their enhanced thickness and grip make them indispensable for both medical and industrial uses, offering users the confidence they need when handling delicate equipment or hazardous materials.

Medical and Healthcare Settings

In medical and healthcare settings, 9.0G Diamond Grip nitrile gloves provide superior barrier protection while maintaining tactile sensitivity. Their thickness helps safeguard against contaminants, making them ideal for procedures that demand precision, such as surgeries or examinations, where compromised sterility can lead to serious consequences.

Industrial and Laboratory Use

In industrial and laboratory settings, these gloves stand out for their robustness and chemical resistance. Industries often deal with hazardous substances, and using 9.0G Diamond Grip nitrile gloves not only protects your hands but also enhances grip and dexterity, which is vital when manipulating laboratory equipment or machinery.

Moreover, when conducting experiments or handling chemicals, the enhanced thickness of 9.0G Diamond Grip nitrile gloves significantly reduces the risk of punctures and tears. For example, in a laboratory conducting chemical analyses, you can confidently handle reagents without the fear of permeation, given that these gloves withstand a variety of aggressive substances, including solvents and oils. This reliability translates into safer, more effective work environments, allowing you to focus on your tasks rather than worrying about personal safety.

Choosing the Right Gloves

When identifying gloves for your specific needs, consider the intended application, level of dexterity required, and any industry regulations you must comply with. The right gloves not only enhance safety but also improve efficiency and comfort during use. Pay attention to factors such as material, fit, and grip to ensure you choose gloves that best suit your operational environment.

Thickness Considerations

The thickness of gloves significantly impacts their performance. For tasks requiring precision, you may prefer thinner gloves that allow for better tactile sensitivity. Conversely, thicker gloves offer enhanced protection against punctures and chemicals, making them suitable for more hazardous environments. Evaluating the demands of your specific tasks can guide you to the right thickness.

Industry Standards

Adhering to industry standards is imperative when choosing gloves, as it ensures compliance with safety regulations. Look for gloves that meet the appropriate testing criteria, such as EN 374 for chemical resistance or EN 421 for protection against radioactive contamination. Selecting gloves that align with these standards can safeguard you from potential hazards in the workplace.

Industry standards not only define the minimum levels of safety but also provide a benchmark for quality. For instance, gloves tested under the EN 420 standard must meet specific ergonomic and performance requirements, ensuring they offer adequate protection while allowing for user comfort. By prioritising gloves that comply with recognised standards, you can enhance safety measures and align your operations with legal and best practice requirements.

Environmental Impact

Environmental Impact

The environmental influence of nitrile gloves requires thoughtful consideration, especially as their usage skyrocketed during health crises. While nitrile is a synthetic rubber, its production process is less detrimental compared to other materials, like latex. Yet, the accumulation of single-use gloves contributes to plastic waste, making it imperative for consumers and industries to adopt eco-conscious practices.

Sustainability of Nitrile Gloves

Nitrile gloves are increasingly produced with sustainability in mind, utilising manufacturing processes that reduce waste and optimise material efficiency. Many brands focus on sourcing materials responsibly, ensuring your consumption aligns with a more sustainable future. This focus enhances their lifecycle, making them a preferable option in various settings.

Disposal and Recycling Options

As far as disposing of nitrile gloves, options vary depending on local regulations. Many facilities recommend incineration to mitigate environmental impact, while emerging recycling programmes focus on transforming used gloves into new products, promoting a circular economy. Explore local facilities’ recommendations for proper disposal methods.

Recycling options for nitrile gloves are becoming more accessible as environmental awareness increases. Some innovative companies are developing programmes specifically designed for collecting used gloves and repurposing them into various materials, such as construction components or fuel. Engaging with these initiatives not only helps to divert waste from landfills but also supports a shift towards more sustainable practices within the industry. By seeking out facilities that offer recycling for nitrile gloves, you can actively contribute to reducing your ecological footprint while benefiting from responsible glove usage.

Conclusion

Considering all points, the thickness of 9.0G Diamond Grip nitrile gloves significantly enhances your safety and performance. The robust material provides improved puncture resistance and durability, allowing you to work with confidence in various environments. Additionally, the unique grip design enhances your control, making tasks easier and more efficient. Investing in these gloves protects your hands while ensuring you maintain a high standard of work. Prioritising thickness in your choice of gloves ultimately leads to a better experience and results in your professional or personal activities.

FAQ

Q: Why is thickness important in nitrile gloves?

A: Thickness in nitrile gloves, such as the 9.0G Diamond Grip, provides enhanced durability and resistance to punctures and tears, ensuring that hands are better protected against harsh chemicals and sharp objects.

Q: How does the thickness of 9.0G Diamond Grip gloves improve grip?

A: The unique design and thickness of the 9.0G Diamond Grip gloves create a textured surface that enhances friction, enabling a more secure hold on various objects, even in wet or oily conditions.

Q: Are thicker gloves less comfortable to wear?

A: The 9.0G Diamond Grip gloves are engineered for comfort despite their thickness. They offer a flexible fit that allows ease of movement while providing robust protection, making them suitable for extended wear.

Q: What specific applications benefit from using 9.0G Diamond Grip gloves?

A: Industries such as healthcare, food processing, and manufacturing benefit significantly from 9.0G Diamond Grip gloves, where both grip and protection are important for safety and efficiency during tasks.

Q: How do 9.0G Diamond Grip gloves compare to other types of nitrile gloves?

A: Compared to standard nitrile gloves, the 9.0G Diamond Grip offers superior thickness and grip, making them ideal for high-risk tasks that require both dexterity and enhanced protection from chemicals and physical hazards.

Understanding Nitrile Gloves

Understanding Nitrile Gloves Importance of Thickness

Importance of Thickness Resistance to Punctures and Tears

Resistance to Punctures and Tears Environmental Impact

Environmental Impact