Architecture demands strength and durability, and structural screws have emerged as vital components in achieving these goals. When choosing fasteners for your projects, understanding how these innovative screws enhance load-bearing capacity, ensure safety, and streamline installation is imperative. With their superior tensile strength and ability to suit various materials, they support the integrity of modern constructions. Opting for structural screws not only optimises your project’s durability but also contributes to a more efficient build process, proving indispensable in today’s architectural landscape.

Key Takeaways:

- Innovative Design: Structural screws feature advanced designs that enhance fastening efficiency and ensure a strong hold, crucial for maintaining structural integrity.

- Versatility: They can be used across a wide range of materials, including wood, metals, and composites, making them adaptable for various architectural applications.

- Time-Saving Installation: The elimination of pre-drilling not only streamlines the installation process but also significantly reduces labour costs on projects.

The Importance of Structural Screws

Before you initiate on your next construction project, understanding the significance of structural screws is vital. These innovative fasteners are designed to enhance your building’s integrity while ensuring compliance with rigorous safety standards. Their advanced features, such as self-starting tips and superior water resistance, provide reliable performance and long-lasting durability, making them vital for modern architecture.

Enhancing Stability and Safety

With structural screws, you greatly improve the stability of your constructions. Their high shear and tensile strength allows them to effectively support heavy loads, ensuring that your structures remain safe over time. This optimal performance is backed by compliance with stringent building codes, which is vital for guaranteeing safety in any construction endeavour.

Applications in Modern Architecture

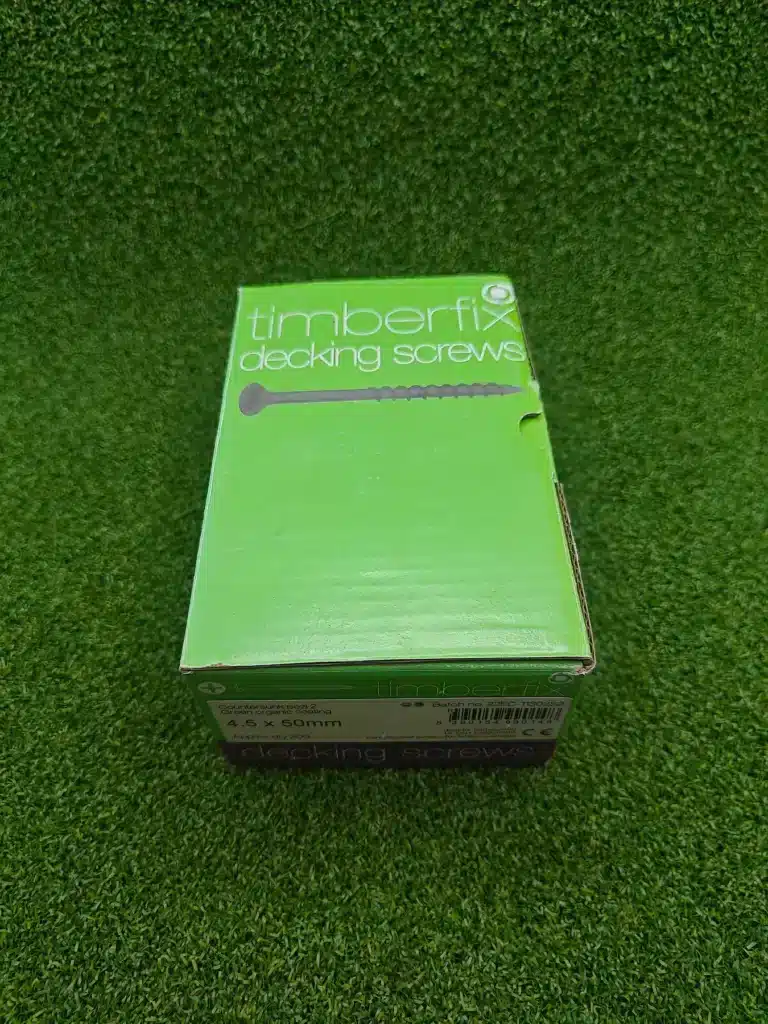

One of the remarkable advantages of structural screws is their versatility in applications. Suitable for a range of materials, including wood, metal, and composites, you’ll find these fasteners ideal for various structural uses, from wooden frames to complex composite decking. This adaptability means you can confidently utilise them in both residential and commercial projects.

And as you explore the practical uses of structural screws, you’ll discover their integral role in modern architecture. Whether you’re framing a new home or constructing a sophisticated design, these screws streamline installation, allow for cost-effective solutions, and provide a reliable connection that has been thoroughly tested for performance. Their ability to eliminate pre-drilling saves invaluable time, enabling you to focus on your project’s overall vision while ensuring a robust and safe structure.

Types of Structural Screws

Assuming you are exploring the various options available for structural screws, it is necessary to understand their types and applications. These screws come in various designs suited for different materials and conditions, including:

| Wood Screws | Designed for wood applications, offering superior holding strength. |

| Metal Screws | Engineered for metal connections, providing durability and reliability. |

| Composite Screws | Optimised for composite materials, ensuring compatibility. |

| High-Strength Screws | Perfect for heavy-duty applications, ensuring structural integrity. |

| Corrosion-Resistant Screws | Coated for durability in outdoor environments, enhancing longevity. |

Recognising the different types of structural screws will enable you to select the best option for your projects.

Wood Screws

Metal Screws

Another aspect to consider is the type of materials used in the manufacturing of metal screws. Some screws are made from high-strength steel, ensuring that they can withstand significant torque and shear forces, making them ideal for applications in heavy-duty and structural components. However, you should be cautious of rust and corrosion if the screws are not properly coated. Investing in galvanised or stainless steel options can provide you with a secure, long-lasting solution that helps maintain the structural integrity of your projects in demanding conditions.

Comparative Strengths of Structural Screws

All fasteners are not created equal, especially when it comes to their strength in structural applications. Below is a comparative analysis that highlights their unique attributes:

| Structural Screws | Exceptional shear and tensile strength; code compliant for reliability. |

| Lag Bolts | Proven strength, ideal for heavy-duty applications like framing and decking. |

Load-Bearing Capacities

Behind every reliable structure is the ability of fasteners to bear significant loads. Structural screws excel in this regard, offering comparable, if not superior, strength to lag bolts, making them suitable for heavy-duty applications where safety is imperative.

Resistance to Environmental Factors

Comparative studies demonstrate that structural screws provide strong resistance against various environmental challenges. They come with advanced coatings to combat corrosion and environmental decay, ensuring longevity in harsh conditions. The benefits include:

- Corrosion Resistance: Coatings protect against rust.

- Weather Resistance: Remain effective in different climates.

- Longevity: Designed for prolonged use and durability.

This ensures that your projects maintain structural integrity over time.

Further analysis reveals that environmental factors can significantly affect the longevity of fasteners used in outdoor settings. Structural screws, with their advanced coatings, resist challenges such as moisture and temperature fluctuations. Consider the following advantages:

- Moisture Protection: Keeps screws secure in wet conditions.

- Temperature Tolerance: Functions effectively across a range of climates.

- Durability: Enhances the lifespan of your installations.

This highlights the advantages of integrating structural screws into your architectural designs to enhance performance and reliability.

Installation Techniques for Structural Screws

Keep in mind that proper installation techniques are vital for maximising the performance of structural screws. Before beginning, ensure you assess the materials and load requirements of your project. Employing appropriate methods ensures a secure fit, maintaining the integrity of your structure over time.

Tools and Equipment

To effectively install structural screws, you will need specific tools such as a power drill, a suitable drive bit for the screw head design, and a torque wrench to apply the correct tension. Additionally, having clamps on hand can help secure materials in place during installation, enhancing stability and accuracy.

Best Practices for Use

Practices to consider include checking for code compliance before installation, ensuring that any fastener you select meets the required safety standards. It’s also advisable to pre-drill when working with denser materials, even though structural screws often allow for pre-drilling-free installation. This precaution promotes a tighter fit and reduces the risk of wood splitting.

Another important aspect to keep in mind is the environmental conditions in which you are working. Always select screws with advanced coatings for enhanced corrosion resistance if you’re working in outdoor or humid environments. When installing, aim for a flush finish with the surface for both aesthetic appeal and structural integrity. By adhering to these best practices, you will ensure that your structural screws perform at their best, contributing significantly to the durability and safety of your project.

Common Misconceptions About Structural Screws

After evaluating the significance of structural screws, it’s necessary to address common misconceptions that may arise. Some builders and remodelers mistakenly assume that structural screws are merely a modern alternative to traditional fasteners, underestimating their strength and versatility. In fact, structural screws are designed with state-of-the-art technology to meet rigorous building codes, ensuring both efficiency and safety in various applications.

Myths Debunked

Common myths surrounding structural screws often suggest that they lack the same holding power as lag bolts, which can lead to hesitation in their use. However, structural screws boast comparable or even superior tensile strength, making them a reliable choice for load-bearing applications in contemporary construction.

Understanding Regulations and Standards

Between the various fasteners available, it’s vital to understand the regulations and standards that govern the use of structural screws in construction. Compliance with building codes ensures that the materials used are robust enough to withstand specific loads and environmental conditions.

To ensure that you are using structural screws appropriately, always check that they are code-approved. This means they have been tested for performance and safety, which is crucial for maintaining the integrity of your structure. Structural screws designed for specific applications can provide you with a secure and durable bond, ultimately preserving your investment while adhering to local building codes. Being aware of these regulations not only impacts the safety and efficacy of your projects but also supports your reputation as a conscientious builder or remodeler.

Future Trends in Structural Fastening

Your understanding of structural fastening is set to evolve as industry trends embrace advanced technologies and materials. Innovations promise to enhance not only the performance of fasteners but also their application across diverse construction sectors. By staying informed about these developments, you can ensure that your projects benefit from the latest solutions available in modern architecture.

Innovations in Material Science

For construction professionals, the ongoing innovations in material science are paving the way for the development of stronger, lighter, and more durable fastening solutions. New composites and coatings are being engineered to withstand various environmental conditions, providing enhanced resistance to corrosion and wear, which ultimately contributes to the longevity and integrity of structures.

The Role of Technology in Design

Role of technology in design has fundamentally transformed the way fasteners are integrated into architectural structures. With software tools and advanced modelling techniques, you can optimise fastening solutions for longevity and performance. This shift not only enhances structural integrity but also reduces installation time and costs. Moreover, utilising technologies like Building Information Modelling (BIM) allows for comprehensive planning and coordination, ensuring that every screw and bolt plays its part effectively.

Final Words

Upon reflecting, it is clear that structural screws play a significant role in modern architecture. As you design and construct your projects, relying on these advanced fastening solutions ensures not only the integrity of your structures but also enhances efficiency during installation. The combination of strength, versatility, and compliance with building codes equips you to meet contemporary construction demands with confidence. Embracing structural screws in your repertoire will undoubtedly elevate the quality and durability of your builds for years to come.

FAQ

Q: What are the advantages of using structural screws in modern architecture?

A: Structural screws offer several advantages in contemporary architecture. Firstly, their high shear and tensile strength make them suitable for load-bearing applications, ensuring the stability and integrity of structures. Secondly, many structural screws are designed to eliminate the need for pre-drilling, which significantly speeds up installation times and reduces labour costs. Additionally, their advanced coatings enhance durability, providing resistance to corrosion and environmental wear, making them ideal for both indoor and outdoor applications. Finally, structural screws are versatile, being compatible with a wide range of materials, including wood, certain metals, and composites.

Q: How do structural screws compare to traditional fastening methods?

A: Structural screws present several benefits over traditional fastening methods such as lag bolts. While lag bolts have a long history of use and are known for their strength, structural screws often provide superior performance through innovative design features. The self-starting tips and specialised threading of structural screws allow for quicker installation without pre-drilling in most cases. Furthermore, their compliance with modern building codes ensures that they meet contemporary safety standards, whereas traditional methods may not always be up to date with the latest regulations.

Q: In which applications are structural screws particularly beneficial?

A: Structural screws are particularly beneficial in various applications across both residential and commercial construction. They are ideal for framing, decking, and securing structural supports, as their strength and ease of installation make them a preferred choice for builders and remodelers alike. Their versatility allows them to be used in areas where traditional methods may be cumbersome or time-consuming. Furthermore, in projects that require precision and a clean finish, structural screws offer a visually appealing solution while maintaining the necessary strength and durability for long-lasting performance.