It’s important to equip yourself with the right tools for every job, and Soudabond Foam should be at the top of your list. This innovative adhesive solution offers exceptional bonding strength, making it ideal for a variety of applications across construction and renovation projects. You’ll find that its versatility and ease of use not only save you time but also enhance the quality of your workmanship. Discover how integrating Soudabond Foam into your toolkit can streamline your projects and improve your results. With its unique Soudabond Foam adhesive properties, this product creates a strong bond with a variety of materials, including wood, metal, and concrete. Whether you’re filling gaps or adhering surfaces, the reliability and consistency of Soudabond Foam ensure that your projects stand the test of time. Embrace the efficiency it brings, allowing you to focus on delivering quality results without the hassle of frequent reapplications.

Key Takeaways:

- Soudabond Foam is versatile, catering to various bonding needs across different materials.

- Its quick curing time enhances efficiency on the job, allowing tradespeople to complete tasks faster.

- The foam offers excellent thermal insulation properties, contributing to energy efficiency in applications.

Overview of Soudabond Foam

Overview of Soudabond Foam

Soudabond Foam is a pioneering polyurethane adhesive that stands out for its versatility and ease of use, making it a preferred choice for tradespeople. It expands on application, filling gaps and providing exceptional bonding strength across a range of surfaces. Its unique formulation ensures that you achieve durable, long-lasting results, whether you’re working with insulation, cladding, or various building materials. This product simplifies the bonding process and enhances efficiency, allowing you to focus on delivering high-quality results.

Composition and Features

This adhesive is primarily made from high-quality polyurethane, which offers impressive elasticity and adhesion properties. Soudabond Foam is designed for one-component use, eliminating the need for mixing, and it sets quickly upon application. The foam expands to fill voids, ensuring a robust bond even in challenging environments. Its lightweight, high-strength formulation makes handling effortless while ensuring consistent performance in various climatic conditions.

Applications in the Trades

You can utilise Soudabond Foam across multiple trades, including construction, insulation installation, and interior finishing. It adheres exceptionally well to diverse materials such as wood, metal, and polystyrene, making it versatile for different project requirements. Whether you’re installing panels, securing insulation, or bonding building components, this adhesive helps streamline your workflow and improve your project’s overall efficiency.

In practice, builders often rely on Soudabond Foam for insulation applications, where its expanding nature fills gaps and enhances thermal efficiency. For instance, when securing insulation boards, you can expect superior adhesion, which significantly reduces energy loss. Moreover, its ease of use allows for quick application during high-paced construction projects, thereby accelerating timelines without compromising on quality. From enhancing structural integrity to facilitating precise installations, the adaptability of Soudabond Foam meets the diverse needs of modern trades. Whether you’re a contractor or a DIY enthusiast, incorporating this adhesive into your toolkit will undoubtedly elevate your workmanship.

Benefits of Using Soudabond Foam

Utilising Soudabond Foam affords you numerous advantages in your trades. Its exceptional bonding capabilities streamline your projects, while its quick curing time significantly reduces downtime. This adhesive is not only versatile, but also adheres seamlessly to a wide range of materials, making it your go-to solution in diverse applications. With Soudabond Foam, you’ll enhance your productivity and achieve reliable results consistently.

Superior Bonding Strength

Superior Bonding Strength

You’ll find Soudabond Foam delivers superior bonding strength that withstands the test of time. Its unique formulation allows it to bond tightly to both porous and non-porous surfaces, ensuring a robust adhesion that meets the demands of any job. This reliability gives you the confidence to tackle complex tasks without worrying about joint failure.

Weather Resistance and Durability

Soudabond Foam’s weather resistance and durability are standout features that make it ideal for outdoor applications. It maintains its strength and performance in varying climates, including extreme temperatures and moisture exposure, ensuring long-lasting bonds that can withstand the elements.

This adhesive is formulated to resist UV light, rain, and extreme temperatures, providing a lasting bond without degradation over time. You can apply Soudabond Foam in diverse weather conditions, making it perfect for external work such as roofing and façades. Its durability shines through in projects where exposure to the elements is a concern, so you can deliver quality workmanship that endures even the harshest conditions.

Environmental Considerations

In today’s construction landscape, environmental impact is a significant factor for tradespeople. Soudabond Foam not only excels in performance but also considers its ecological footprint, ensuring that you can fulfil your projects while being environmentally responsible.

Eco-Friendly Properties

Soudabond Foam features eco-friendly properties that minimise its impact on the environment. It is free from harmful solvents and is manufactured with a focus on reducing volatile organic compounds (VOCs), making it a safer choice for indoor applications.

Safety Standards and Certifications

The adhesive meets stringent safety standards and is certified for both efficiency and environmental safety. This ensures that when you choose Soudabond Foam, you comply with industry regulations while also promoting a safer work environment.

With certifications like ISO 14001 for environmental management and EN 14080 for construction adhesives, Soudabond Foam illustrates its commitment to high safety and sustainability standards. These certifications are crucial not only for regulatory compliance but also for instilling confidence among your clients about the safety of materials used in their projects. Utilising Soudabond ensures that your work aligns with best practices in environmental responsibility and safety.

User Testimonials and Case Studies

Numerous tradespeople have noted the standout performance of Soudabond Foam through various testimonials and case studies, highlighting its impact on productivity and quality of work. The following examples showcase real-world applications and the advantages experienced by users across different trades.

- Case Study 1: A flooring contractor reported a 30% reduction in installation time when using Soudabond Foam compared to traditional adhesives.

- Case Study 2: An insulation specialist achieved a 100% adhesion success rate, even in challenging weather conditions.

- Case Study 3: A contractor noted that Soudabond Foam provided a 40% increase in material yield, cutting costs significantly.

- Case Study 4: A roofing expert experienced a 25% reduction in callbacks related to adhesive failures.

Success Stories from Tradespeople

Success Stories from Tradespeople

Many tradespeople have shared their success stories about integrating Soudabond Foam into their workflows. One carpenter highlighted how the adhesive’s rapid curing time allowed him to complete projects ahead of schedule, leading to increased client satisfaction and more referrals. Similarly, a plasterer praised the ease of application, which reduced labour costs and enhanced overall project efficiency.

Comparison with Other Adhesive Solutions

When comparing Soudabond Foam to traditional adhesive solutions, the differences are notable. While conventional adhesives often require lengthy curing times and intricate application methods, Soudabond offers a fast and straightforward process, significantly boosting productivity. Moreover, its superior bond strength has been demonstrated to outperform other brands, ensuring reliability in various applications.

Comparison of Soudabond Foam and Traditional Adhesives

| Feature | Soudabond Foam |

| Curing Time | Fast (minutes) |

| Bond Strength | High |

| Application Ease | Very Easy |

| Cost Efficiency | High yield, lower waste |

In further comparison, traditional adhesives often require multiple application tools and lengthy drying times, limiting efficiency. Soudabond Foam simplifies the process, allowing for immediate handling and faster overall project completion. Additionally, its ability to form a strong, lasting bond across various materials gives you confidence in its performance, something that isn’t always guaranteed with other products.

Additional Insights on Adhesive Performance

| Factor | Soudabond Foam |

| Weather Resistance | Excellent |

| Usage for Multiple Materials | Versatile (wood, metal, etc.) |

| Environmental Impact | Low VOCs |

| Longevity | Long-lasting bond |

Application Techniques and Best Practices

Application Techniques and Best Practices

Effective application of Soudabond Foam can significantly enhance your projects. Begin with a clean, dry surface for maximum adhesion, and ensure that ambient temperature is within the recommended range for optimal performance. Employ consistent, even pressure on the trigger to achieve uniform foam output and avoid over-expansion. Practising this technique results in cleaner application and prevents wastage.

Tools and Equipment Needed

You will need a caulking gun suitable for high viscosity foams, a utility knife for trimming excess foam, and safety gear such as gloves and goggles. Additionally, having a tape measure and a level will help ensure precise application, allowing for better alignment and stability in your project.

Step-by-Step Application Guide

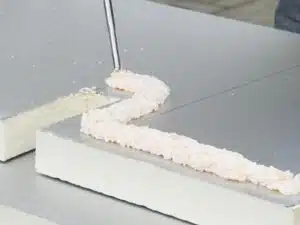

Begin by preparing your surface, ensuring it is free from dust and debris. Following that, cut the nozzle of the Soudabond Foam cartridge at a 45-degree angle to control the flow. Shake the canister thoroughly before loading it into your caulking gun. At a consistent angle, apply the foam in a zigzag motion, covering the required area before allowing it to cure as per manufacturer instructions.

Step-by-Step Application Guide

| Step 1: Prepare the surface. | Clean and dry the area. |

| Step 2: Cut the nozzle. | Angle cut for precision. |

| Step 3: Load the cartridge. | Ensure a firm grip in the caulking gun. |

| Step 4: Apply the foam. | Use a zigzag motion for even coverage. |

| Step 5: Allow to cure. | Check manufacturer’s guidelines for timing. |

The step-by-step guide serves to streamline your application process, fostering efficiency. Starting with surface preparation ensures the best bond, while the nozzle cutting technique facilitates control over foam distribution. By maintaining a consistent angle and pressure while applying the foam, you minimise waste and enhance adhesion. Lastly, adhering to curing times not only guarantees structural integrity but also optimises the performance of Soudabond Foam in your projects.

Additional Insights on Applying Soudabond Foam

| Tip 1: Inspect the foam coverage. | Ensure no gaps are visible. |

| Tip 2: Use a damp cloth. | Clean excess foam before it cures. |

| Tip 3: Store properly. | Keep cartridges in a cool, dry place. |

Cost-Effectiveness and Value

The cost-effectiveness of Soudabond Foam is evident when considering its efficient application and minimisation of waste. The versatility of this adhesive means fewer products are needed for various tasks, allowing you to save money without compromising on quality. Ultimately, the long-lasting performance of Soudabond Foam ensures that your investment delivers significant value far beyond the initial expense.

Long-Term Savings

Long-Term Savings

Using Soudabond Foam translates to long-term savings in both materials and labour. Its superior bonding capabilities reduce the need for additional products, while its durability minimises the risk of repairs or replacements. This not only saves you money, but also cuts down on the time and effort spent on projects.

Investment in Quality

Investing in quality means opting for solutions like Soudabond Foam, which is specifically designed to meet high-performance standards. The formula ensures exceptional adhesion to a wide range of substrates, making it a reliable choice for diverse applications. By choosing a premium adhesive, you enhance the longevity of your projects and bolster your reputation as a tradesperson committed to high standards.

The investment in Soudabond Foam pays off through its exceptional performance in both commercial and residential settings. Designed to offer optimal adhesion under varying conditions, it stands up against moisture, temperature fluctuations, and other common challenges in construction and refurbishment. This not only enhances the durability of your work but also reassures your clients, leading to increased trust and potential referrals. Choosing a product backed by proven results positions you favourably within the competitive landscape, ensuring you deliver projects that are not only effective but also enduring.

To wrap up

From above, it is clear that Soudabond Foam presents imperative benefits for your trade. This versatile adhesive not only offers superior bonding strength but is also easy to apply, saving you time on the job. Its ability to fill gaps enhances insulation and improves the overall quality of your work. By choosing Soudabond Foam, you equip yourself with a reliable solution that can elevate your craftsmanship and meet the demands of various projects. Investing in Soudabond Foam is a smart choice for any tradesperson aspiring for excellence.

FAQ

Q: What is Soudabond Foam?

A: Soudabond Foam is a one-component, polyurethane adhesive foam specifically designed for construction and building applications. It expands on application, providing excellent adhesion and insulation properties.

Q: Why should tradespeople choose Soudabond Foam over traditional adhesives?

A: Soudabond Foam offers faster application, exceptional bonding strength, and thermal insulation compared to traditional adhesives. Its expanding nature fills gaps and irregularities, ensuring a secure hold.

Q: In what applications can Soudabond Foam be used?

A: Soudabond Foam is suitable for various applications, including bonding insulation materials, fixing window frames, and installing roof coverings. Its versatility makes it ideal for both interior and exterior projects.

Q: How does the curing process of Soudabond Foam work?

A: Soudabond Foam cures by absorbing moisture from the air, which results in an expanding foam that hardens over time. This process ensures strong adhesion and effective insulation once fully cured.

Q: What safety precautions should be taken when using Soudabond Foam?

A: When using Soudabond Foam, it is important to wear appropriate personal protective equipment, such as gloves and goggles, as the foam can be irritating to the skin and eyes. Ensure proper ventilation in the working area to avoid inhalation of fumes.

Overview of Soudabond Foam

Overview of Soudabond Foam Superior Bonding Strength

Superior Bonding Strength Success Stories from Tradespeople

Success Stories from Tradespeople Application Techniques and Best Practices

Application Techniques and Best Practices Long-Term Savings

Long-Term Savings