With an understanding of the strengths and weaknesses of screws and nails, you can enhance the durability of your projects. While nails are ideal for quick fixes and can offer flexibility, screws provide superior holding power and stability, particularly in weight-bearing applications. Choosing the right fastening method can prevent structural failures and ensure your work stands the test of time. By recognising when to use each, you will fortify your creations and save yourself from potential hazards.

Key Takeaways:

- Screws provide superior holding power and are ideal for applications requiring strong and secure joints.

- Nails are quicker to install and more suitable for framing and structures where flexibility is advantageous.

- Consider the materials being joined and the specific load requirements when choosing between screws and nails.

Understanding Screws

Understanding Screws

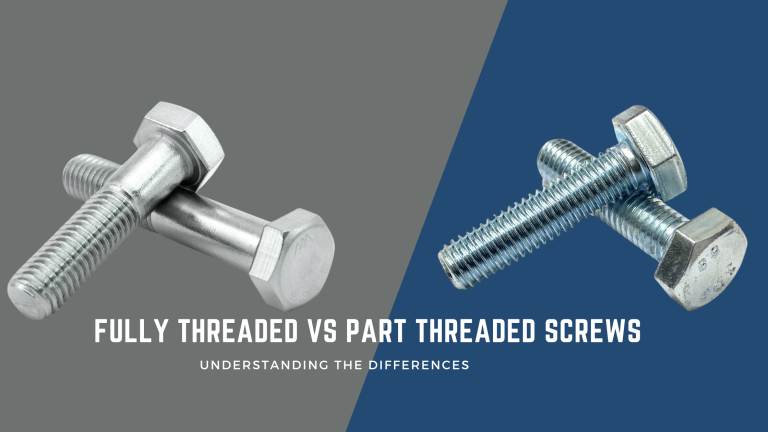

Screws serve as versatile fastening solutions, providing superior grip and holding power compared to nails. They consist of a cylindrical shaft with a sharp end for penetration and helical threads for enhanced friction. The unique design makes screws ideal for various materials, ensuring a strong connection that withstands stress and movement.

Types of Screws

Several types of screws cater to different applications:

- Wood screws: Designed for use in timber, featuring coarse threads for better grip.

- Machine screws: Utilised in metal-to-metal connections, requiring a pre-drilled hole.

- Sheet metal screws: Ideal for fastening metal sheets together, with sharp points that cut through material.

- Self-tapping screws: Create their own hole, making installation easier without pre-drilling.

- Lag screws: Heavy-duty screws that offer strong anchors for structural supports.

Recognising the right type of screw for your project can significantly enhance your fastening effectiveness.

| Type | Application |

| Wood screws | Timber fastening |

| Machine screws | Metal connections |

| Sheet metal screws | Metal sheets |

| Self-tapping screws | No pre-drilling needed |

Advantages of Using Screws

Advantages of Using Screws

The advantages of using screws are diverse, making them a preferred choice for many projects. Screws provide a stronger hold compared to nails, especially in applications requiring durability. Their ability to be easily removed and reused without compromising structural integrity is another benefit. Additionally, screws reduce the risk of wood splitting, especially in tight connections.

With screws, you can often achieve a more secure fastening than with nails, as their threads engage the material more effectively, creating a bond that resists pulling out. The versatility in various screw types also means that you can select the most suitable one for your specific task, allowing for greater control over the strength and durability of your work. This adaptability proves beneficial in complex projects, streamlining the process and enhancing stability.

Understanding Nails

Nails serve as crucial fasteners in various construction and DIY projects, providing effective joining methods for wood and other materials. Their simple design allows for quick application and removal without specialised tools. With a variety of sizes and styles available, nails can accommodate different tasks, from framing to finishing touches.

Types of Nails

- Common nails – used for framing and general construction.

- Finish nails – ideal for trim and moulding.

- Box nails – thinner than common nails, for lighter duty.

- Brad nails – used in delicate projects, such as woodworking.

- Roofing nails – specifically for attaching roofing materials.

After understanding the types, you can select the right nail for your project.

| Type of Nail | Usage |

| Common nails | Framing |

| Finish nails | Trim work |

| Box nails | Lighter materials |

| Brad nails | Fine woodworking |

Advantages of Using Nails

Advantages of Using Nails

Nails offer distinct advantages compared to other fasteners, making them versatile for various applications. They provide excellent tensile strength, especially in softwoods, and can be removed easily without damaging the surrounding material. Their speed of installation is unmatched, allowing for rapid assembly with a simple hammer or nail gun.

Nails can often be driven in quicker than screws, making them a faster choice for framing or subflooring. Additionally, they bend slightly under stress, providing flexibility and stability in structures. This becomes particularly useful in scenarios where movement is expected, as nails minimize the risk of splitting wood and breaking under pressure. Their cost-effectiveness also contributes to their widespread use in both professional settings and personal projects.

Comparing Strength and Durability

| Screws | Nails |

|---|---|

| Higher load-bearing capacity, suitable for heavy-duty applications. | Good for lighter loads and quicker installation. |

| Greater resistance to withdrawal and shear forces. | Less resistant to withdrawal; can work loose over time. |

| Corrosion-resistant options available, increasing lifespan. | Generally less durable unless specially treated. |

Load-Bearing Capacity

Screws excel in load-bearing capacity, allowing you to secure heavy materials or structures with confidence. When fastening timber beams or metal brackets, screws provide superior strength due to their threaded design, which locks into place, distributing the load evenly and effectively. This makes them the preferred choice for applications like furniture assembly or structural framing.

Resistance to Withdrawal

When considering withdrawal resistance, screws offer significant advantages over nails. The threads of a screw grip the material tightly, preventing it from loosening over time, even under shifts in temperature or pressure. In contrast, nails can gradually work free, especially in environments subject to vibrations or heavy loads.

The ability of screws to resist withdrawal is particularly vital in structural applications. For instance, when securing decking boards or attaching heavy fixtures, screw fixation ensures stability and safety. With larger diameters and varying thread designs, screws can further enhance retention in different materials, making them an indispensable choice for robust construction. This property is vital when your project demands durability and long-term performance.

Applications for Screws

Screws offer exceptional versatility across various applications, excelling in scenarios requiring precise fastening. They’re ideal for securing wood, metal, and plastic, with options like self-tapping screws simplifying assembly in challenging materials. In furniture construction, cabinetry, and even in electrical work, screws provide a durable fixing that withstands forces such as torque and tension, making them suitable for both structural and aesthetic purposes.

Ideal Use Cases

Utilise screws in projects that demand a strong connection, like building frames or assembling outdoor furniture subjected to the elements. They excel in areas where disassembly might be necessary, such as storage solutions and electrical fittings. In such cases, screws provide the option for easy removal without damaging the materials.

Best Practices

Best Practices

To ensure optimal performance, pre-drill pilot holes when fastening screws into harder materials, which reduces the risk of splitting and improves alignment. Always select the correct screw length and thickness for your materials; longer screws offer more holding power but can cause damage if oversized. Maintain consistent spacing between screws to avoid structural weaknesses.

Pre-drilling is particularly effective for hardwoods, preventing splits and making driving easier, while using the right screwdriver bit ensures proper engagement with the screw head, reducing wear. Additionally, consider using screws with coatings such as galvanisation or epoxy to enhance corrosion resistance, especially in outdoor applications. For maximum strength, drive screws perpendicular to the joining surfaces, as this alignment optimises the load-bearing capabilities of your fixing. Always check for the compatibility of materials and fasteners to guarantee a secure and lasting bond.

Applications for Nails

Nails find frequent application in various construction tasks, especially when quick assembly is required or when fastening materials where they may experience low stress levels. Common uses include framing, roofing, and sheathing, as nails can penetrate through multiple sheets of material effectively. Wood-to-wood connections, such as decking and fencing, are also ideal scenarios for using nails, offering reliable structural integrity in non-load-bearing situations.

Ideal Use Cases

Opt for nails in projects where speed is vital and high tensile strength is not a concern. For instance, light framing or attaching panels is best suited for nails, as they allow for faster installation and can flex under pressure without splitting the wood easily. Projects like drywall installation also benefit from nails due to their rapid application and adequate holding power in lightweight materials.

Best Practices

Using the right type and size of nail is fundamental for achieving strong fixings. Opt for galvanised nails for outdoor use to prevent rusting, especially in exposed areas. Ensure you use a nail gun or hammer with precision to avoid damaging the material, and drive nails at an angle when fastening joints to enhance stability. Keeping a consistent distance between nails (typically one to two inches apart) ensures even load distribution.

Employing these best practices can significantly enhance the performance and durability of your projects. For instance, when framing, selecting 3.2mm to 4.0mm diameter nails provides optimal strength for structural elements. Effective spacing not only prevents wood splitting but also supports better adherence. Always pre-drilling in denser materials can minimise the risk of damage and ensure the nails drive smoothly for a tidy finish.

Common Mistakes to Avoid

Avoiding missteps in fastening techniques can significantly improve your projects’ integrity. Numerous errors arise from a lack of knowledge about fasteners and their appropriate applications, leading to weak connections or structural failures. Understanding the intricacies of your materials and tasks will prevent these common pitfalls and ensure that your work stands the test of time.

Misuse of Fasteners

Using the wrong type of fastener for your specific project can compromise strength and safety. For example, employing screws where nails are needed may lead to unwanted splitting of timber, while nails in applications designed for screws can result in loose connections. Always evaluate the requirements of your materials before selecting a fastener.

Choosing the Wrong Size

Incorrectly sized fasteners can lead to insufficient holding power or damage to materials. Fasteners that are too long can protrude through the other side, posing hazards, while those that are too short may not provide the necessary grip. For instance, a 50mm screw in a 25mm thick plank risks breaking through the surface, while a 25mm screw may pull out under load, undermining your entire project.

Summing up

Presently, understanding when to use screws versus nails can significantly enhance the strength of your fixings. If your project requires a strong, permanent hold, screws are preferable due to their ability to create a tighter grip and resist loosening over time. In contrast, nails are ideal for quick fastening and flexibility, particularly in framing or temporary applications. Assess your project’s needs carefully, and choose the appropriate fastener to ensure the durability and stability of your work.

FAQ

Q: What are the main differences between screws and nails?

A: Screws have threads that provide grip and are better for tensile strength, making them ideal for applications where pulling forces are involved. Nails have a smooth shaft, which allows for quicker installation but generally offers less holding power compared to screws.

Q: When should I use screws instead of nails?

A: Use screws when you require a stronger hold in materials such as hardwood or for applications involving tension, such as securing joints in furniture or fixing areas that may experience movement.

Q: Are there specific projects where nails are preferred over screws?

A: Nails are preferred for framing, roofing, or when working with softer woods where speed of installation is important and the holding power needed is less critical. They can also be suitable for applications that require flexibility.

Q: How does moisture affect the choice between screws and nails?

A: In moist environments, screws are generally better due to their greater corrosion resistance, especially when using coated or stainless steel screws. Nails can rust more easily, which can lead to structural weaknesses over time.

Q: Can I replace nails with screws in existing projects?

A: While it is possible to replace nails with screws, consider the material you are working with and the type of load it will bear. Screws can provide a stronger connection, but ensure you use the appropriate size and type to avoid damaging the material.

Understanding Screws

Understanding Screws Advantages of Using Screws

Advantages of Using Screws Advantages of Using Nails

Advantages of Using Nails Best Practices

Best Practices