Most workshops involve tasks that can expose you to hazardous materials and sharp tools, making protective gear indispensable. Heavy duty nitrile gloves offer exceptional resistance to punctures, chemicals, and oils, ensuring your hands remain safe while you work. These gloves provide a reliable barrier without compromising dexterity, allowing you to handle tools and materials with confidence. Additionally, their durable construction means they can withstand rigorous use, making them a practical choice for your workshop activities.

Key Takeaways:

- Heavy duty nitrile gloves provide enhanced protection against chemicals and contaminants commonly found in workshops.

- The gloves offer superior puncture resistance, ensuring durability for various tasks without compromising safety.

- They provide a secure grip and dexterity, allowing for precise handling of tools and materials while maintaining safety standards.

Benefits of Heavy Duty Nitrile Gloves

Benefits of Heavy Duty Nitrile Gloves

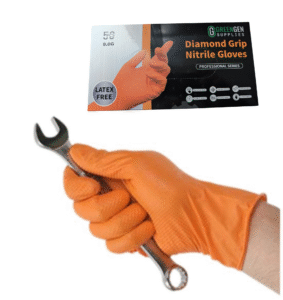

Utilising heavy duty nitrile gloves in your workshop brings numerous benefits, enhancing both safety and performance. These gloves provide exceptional protection against a wide range of chemicals and hazardous substances, ensuring that you can handle tasks with confidence. Additionally, their design prioritises comfort and flexibility, allowing for precise movements while maintaining a reliable grip. As a result, choosing these gloves means you can focus on your work without compromising your safety or the quality of your projects. Furthermore, heavy duty nitrile gloves benefits extend beyond just protection; they are also resistant to punctures and tears, making them a durable choice for demanding tasks. Their ability to provide a barrier against oils and solvents further enhances their utility in various workshop environments. Embracing these gloves not only safeguards your hands but also contributes to improving overall productivity and efficiency in your work.

Chemical Resistance

Heavy duty nitrile gloves are renowned for their impressive chemical resistance. This allows you to handle solvents, oils, and various other hazardous materials without worrying about degradation or skin exposure. Their ability to withstand harsh substances makes them ideal for diverse workshop applications, ensuring your safety is never compromised while you work on challenging tasks.

Durability and Puncture Protection

The design of heavy duty nitrile gloves offers superior durability and puncture protection. Made from high-quality materials, these gloves can withstand rigorous use, preventing tears or punctures during demanding tasks. This resilience not only extends their lifespan but also ensures that you remain shielded from sharp objects and abrasive surfaces, fostering a safer work environment.

In the context of durability and puncture protection, heavy duty nitrile gloves truly stand out. They are engineered to provide a high tensile strength, meaning they can endure significant force without failing. For instance, these gloves are typically thicker than standard options, often exceeding 5 mils in thickness, enabling them to resist cuts and punctures effectively. Workshops often involve sharp tools and materials; thus, wearing gloves that can protect against accidental punctures or tears is important. Opting for these reliable gloves means you invest in your safety, allowing you to work on tasks with greater peace of mind and confidence in your protection.

Comfort and Fit

Comfort and Fit

A comfortable fit is crucial for effective performance in the workshop. Heavy duty nitrile gloves are designed to provide a snug yet flexible fit, allowing you to work for extended periods without discomfort. This balance of comfort and fit reduces hand fatigue, enabling you to focus on your tasks without the distraction of ill-fitting gloves.

Ergonomic Design

The ergonomic design of heavy duty nitrile gloves supports natural hand movements, allowing you to manoeuvre tools and materials with ease. This design ensures that the gloves conform to the contours of your hands, significantly enhancing your overall user experience while promoting better control over intricate tasks.

Sensitivity and Dexterity

When working in a workshop, sensitivity and dexterity are vital for precision tasks. Heavy duty nitrile gloves maintain a high level of tactile sensitivity, which permits you to feel the textures and movements of objects you are handling. This sensitivity allows you to perform delicate tasks without compromising protection.

With a thickness that balances protection and flexibility, heavy duty nitrile gloves can help you retain full tactile feedback. Whether you’re working with small components or handling tools, these gloves enable you to grip and manipulate items with precision. The texture on the gloves further enhances grip, ensuring that you can perform tasks requiring fine motor skills effortlessly, which is especially beneficial in detailed assembly or repair work.

Versatility in Different Workshops

Heavy duty nitrile gloves demonstrate remarkable versatility across various workshop environments, making them a must-have for professionals and enthusiasts alike. From automotive repair to woodworking, these gloves adapt easily to different tasks, providing necessary protection without compromising dexterity. Their resistance to punctures and chemicals ensures you can handle a range of materials confidently, no matter your specific workshop needs.

Automotive Applications

Automotive Applications

In the automotive sector, heavy duty nitrile gloves are invaluable for mechanics and technicians. They shield your hands from oils, solvents, and other hazardous substances encountered during repairs and maintenance. The non-slip grip offers additional control when working with tools and small components, allowing you to perform tasks safely and efficiently.

Industrial Uses

Heavy duty nitrile gloves excel in industrial environments, offering superior protection against various chemicals and contaminants. Their robust design ensures durability, making them suitable for heavy lifting, assembly lines, and maintenance tasks. You can also easily dispose of them after use, providing a practical solution for maintaining hygiene standards in the workplace.

In industrial settings, heavy duty nitrile gloves are used daily in sectors like manufacturing, construction, and waste management due to their resilience against abrasives and chemicals. They provide a barrier against harmful substances like acids and alkalis, ensuring your skin remains protected. With options of varying thicknesses, you can select gloves tailored to the specific hazards of your job, enhancing productivity while ensuring safety protocols are adhered to. In addition, their latex-free composition benefits those with allergies, promoting a safer working environment for everyone.

Cost-Effectiveness

Investing in heavy-duty nitrile gloves proves to be cost-effective in the long run. Though the initial purchase price may be higher than standard gloves, their durability reduces the frequency of replacement. This longevity translates to lower overall costs for workshops, allowing you to allocate funds to other imperative equipment or materials. Additionally, using quality gloves minimises the risk of contamination and damage to tools, further enhancing your workshop’s operational efficiency.

Longevity and Value

Heavy-duty nitrile gloves offer exceptional longevity compared to their latex or vinyl counterparts. The robust material withstands wear and tear from various workshop tasks, enabling you to use fewer pairs over time. This durability not only ensures reliable protection but also represents a significant value proposition, reinforcing the idea that quality gloves can serve your needs effectively and economically.

Reduction in Workplace Injuries

Utilising heavy-duty nitrile gloves significantly reduces the risk of workplace injuries. Their protective qualities safeguard your hands from chemicals, sharp objects, and abrasions, creating a safer work environment. This proactive measure not only helps prevent accidents but also fosters a culture of safety, encouraging diligence in safety practices across your team.

Statistics demonstrate a concrete link between proper hand protection and decreased injury rates. Workplaces that adhere to strict safety protocols, including the use of heavy-duty nitrile gloves, report up to a 60% reduction in hand injuries. Adopting such protective gear not only safeguards your well-being but also minimises disruption from accidents, leading to improved productivity and morale within your workshop.

Comparison with Other Glove Materials

| Material | Advantages |

|---|---|

| Nitrile Gloves | Highly durable, resistant to punctures and chemicals. |

| Latex Gloves | Excellent flexibility and tactile sensitivity. |

| Vinyl Gloves | Cost-effective and ideal for low-risk tasks. |

Latex Gloves

While latex gloves offer superior flexibility and tactile sensitivity, they can cause allergic reactions in some individuals. This restricts their use in environments where staff safety is paramount. They provide less chemical resistance compared to nitrile, making them less suitable for tougher workshop tasks.

Vinyl Gloves

Vinyl gloves are often the go-to choice for low-risk environments due to their affordability and availability. However, they lack the durability and chemical resistance that nitrile gloves provide. Thus, they are best suited for quick, low-exposure tasks rather than heavy-duty applications.

Although vinyl gloves may be appropriate for food handling or light cleaning, their filtration abilities and puncture resistance are limited compared to nitrile. Consequently, they can easily tear under rigorous conditions, which poses a risk when handling sharp tools or hazardous materials. Opting for nitrile gloves ensures better protection and longevity in demanding workshop settings.

Best Practices for Use and Disposal

Best Practices for Use and Disposal

To ensure maximum safety and efficiency, follow best practices when using and disposing of heavy-duty nitrile gloves. Always check for integrity before use, and make sure to wear them correctly to prevent contamination. After use, dispose of gloves in designated waste bins to comply with safety regulations and minimise environmental impact. Regular training on proper techniques can also enhance safety in the workshop.

Proper Donning and Doffing Techniques

When donning gloves, ensure your hands are clean and dry; gently slide the gloves on, avoiding contact with the exterior. When doffing, remove them without touching the outer surface by pinching the wrist and turning them inside out as you pull them off. This technique reduces the risk of cross-contamination.

Eco-Friendly Disposal Methods

Disposing of heavy-duty nitrile gloves responsibly helps protect the environment. Many facilities now offer dedicated bins for hazardous waste, including gloves, ensuring safe disposal. Additionally, some companies have implemented recycling programmes specifically for nitrile products, allowing you to contribute to sustainable practices without compromising safety.

In the UK, various recycling initiatives are emerging, focusing on transforming nitrile gloves into useful products rather than allowing them to end up in landfills. For instance, certain companies specialise in converting gloves into fuel or using them in road construction. By participating in these eco-friendly disposal options, you not only comply with regulations but also significantly reduce your environmental footprint, demonstrating a commitment to sustainability in the workplace.

Summing up

Following this, using heavy-duty nitrile gloves in your workshop enhances your safety and protection against hazardous materials. These gloves offer superior resistance to chemicals and punctures, ensuring your hands remain unharmed during tasks. Their durability provides the confidence you need while working with tools and substances, without compromising on dexterity. Additionally, the comfortable fit allows for extended use without discomfort, making them a practical choice for any workshop environment. Prioritising your safety with the right protective gear ultimately contributes to improved productivity and peace of mind.

FAQ

Q: What are heavy duty nitrile gloves?

A: Heavy duty nitrile gloves are protective hand coverings made from a synthetic rubber material known as nitrile. They offer high levels of durability and resistance to punctures, chemicals, and abrasions, making them ideal for use in workshop environments.

Q: What are the advantages of using heavy duty nitrile gloves in the workshop?

A: The advantages include excellent chemical resistance, enhanced grip, comfort during prolonged use, reduced risk of allergic reactions due to their latex-free composition, and increased durability compared to standard gloves, providing better protection for hands.

Q: Can heavy duty nitrile gloves be reused?

A: While some heavy duty nitrile gloves can be reused if they are not excessively contaminated or damaged, it is generally advisable to dispose of them after a single use in hazardous situations to ensure maximum safety and hygiene.

Q: How do heavy duty nitrile gloves fit compared to other types of gloves?

A: Heavy duty nitrile gloves typically offer a snug fit that enhances tactile sensitivity. This fit is beneficial in workshop settings, where precision is important. They are designed to stretch and conform to the shape of the hand without compromising protection.

Q: Are heavy duty nitrile gloves suitable for all workshop tasks?

A: Yes, heavy duty nitrile gloves are suitable for a wide range of workshop tasks, including handling chemicals, working with machinery, and performing maintenance duties. However, for tasks requiring extreme heat resistance, specialised gloves may be more appropriate.

Benefits of Heavy Duty Nitrile Gloves

Benefits of Heavy Duty Nitrile Gloves Comfort and Fit

Comfort and Fit Automotive Applications

Automotive Applications Best Practices for Use and Disposal

Best Practices for Use and Disposal