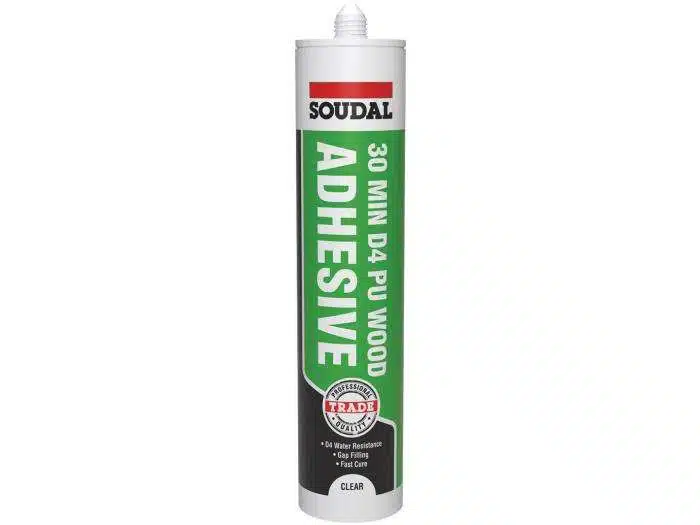

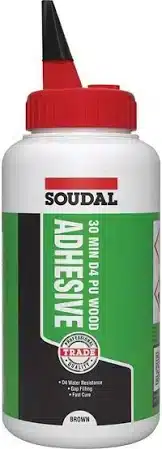

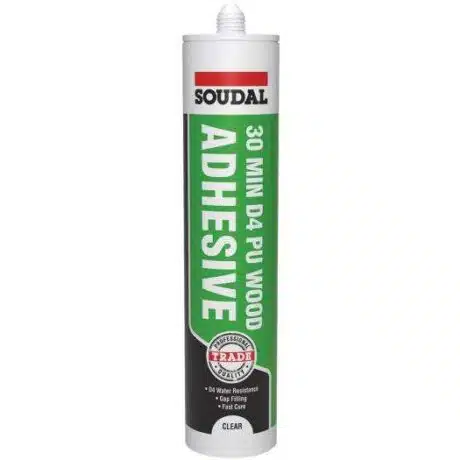

Soudal D4 PU Wood Glue | High-Strength Waterproof Polyurethane Timber Adhesive (EN 204 D4)

- D4 water‑resistant classification (EN 204) – suitable for interior and exterior joinery exposed to frequent or prolonged moisture.

- High‑strength structural bond – creates a very strong, durable timber joint, ideal for load‑bearing applications when properly designed.

- Gap‑filling, foaming action – slight expansion helps fill small gaps and irregularities in timber joints for better contact.

- Bonds a wide range of woods & materials – suitable for softwoods, hardwoods, MDF, chipboard, plywood and some non‑porous substrates (after testing).

- Fast curing – rapid strength development helps speed up clamping and assembly times on site and in the workshop.

Free shipping on orders over £60

- No-Risk Money Back Guarantee!

- No Hassle Refunds

- Secure Payments

Soudal D4 PU Wood Glue – High‑Strength, Waterproof D4 Polyurethane Timber Adhesive

Soudal D4 PU Wood Glue is a professional‑grade, D4‑rated polyurethane wood adhesive

designed for high‑strength, waterproof bonding of softwood, hardwood and many wood‑based

panels. Ideal for exterior joinery, structural timber work (when specified), furniture,

doors, windows and general woodworking where a tough, long‑lasting bond is essential.

Soudal D4 PU Wood Glue is a one‑component, moisture‑curing polyurethane

adhesive specifically developed for demanding wood bonding applications where high

bond strength and excellent water resistance are required. Classified as D4 to EN 204,

it is suitable for indoor applications with frequent long‑term exposure to running or

condensed water, and for outdoor applications exposed to weather, when the bonded

joint is properly protected by an appropriate coating system.

The adhesive reacts with moisture in the wood and ambient air, foaming slightly and

expanding to fill small gaps within the joint. Once cured, it forms a rigid, durable

bond line with excellent resistance to water, many chemicals and elevated temperatures

(within the limits stated by the manufacturer). This makes Soudal D4 PU Wood Glue particularly

suited to:

- Exterior joinery – doors, windows, gates, fascia and cladding components.

- Timber construction and structural elements – beams, posts, trusses and timber frame joints (when designed and specified accordingly).

- Furniture and interior joinery – kitchens, bathrooms, laminated worktops, stairs and handrails.

- General carpentry & site work – bonding of C16/C24 structural timber, sheet materials and trim (follow engineering and Building Regulation requirements).

Typical Use Cases

- External door and window manufacturing – bonding stiles, rails, mullions and glazing beads in hardwood and softwood joinery exposed to weather.

- Timber frame and structural work – supplementing mechanical fixings in C16/C24 structural timber joints such as beams, studs and truss nodes (when approved by the designer/specifier).

- Furniture and staircase assembly – high‑strength bonding of treads, risers, stringers, rails, posts and balusters where durability and moisture resistance are needed.

- Worktop and panel bonding – laminating and edge bonding MDF, chipboard, blockboard and plywood in kitchens, bathrooms and utility areas.

- General exterior repairs – repairing and bonding garden furniture, gates, sheds and outdoor timber structures.

Installation & Application Tips

- Substrate preparation:

- Ensure all bonding surfaces are clean, sound and free from dust, grease, oil, wax and loose fibres.

- For best results, surfaces should be planed or sanded to provide a close‑fitting joint; very large gaps should be corrected mechanically.

- The wood moisture content should normally be within the range recommended for joinery and structural timber (typically 8–18%, check relevant standards/project spec).

- Moistening the surfaces:

- Soudal D4 PU Wood Glue is a moisture‑curing adhesive; slightly dampening one substrate (e.g. with a fine water mist) can improve curing, especially on very dry timber.

- Avoid over‑wetting – surfaces should be lightly damp, not soaked.

- Application of adhesive:

- Apply a continuous, even bead or thin film of glue to one of the bonding surfaces using the nozzle or a spreader.

- Typical application rate is in line with manufacturer guidance (often in the region of 150–250 g/m² of bonding surface, check datasheet).

- Do not apply excessively thick layers; the adhesive foams on curing and is designed for close‑fitting joints.

- Assembly & clamping:

- Bring the parts together within the open time specified on the datasheet, ensuring correct alignment.

- Apply even clamping pressure across the joint using clamps, presses or fixings to maintain contact during cure.

- Avoid over‑tightening to the point of starving the joint of adhesive.

- Curing & finishing:

- Excess adhesive that foams out of the joint can be allowed to cure and then carefully trimmed or sanded off.

- Initial handling strength is usually achieved within a few hours, with full cure typically after 24 hours depending on temperature, humidity and joint geometry.

- Once fully cured, the bond can be planed, sanded, drilled, screwed and painted.

- Clean‑up:

- Uncured PU glue can be removed from tools and surfaces with a suitable PU cleaner or solvent (as recommended by Soudal).

- Cured adhesive can only be removed mechanically (scraping, sanding, chiselling).

Technical & Performance Overview

Soudal D4 PU Wood Glue is manufactured and tested to meet EN 204 D4 requirements

for water‑resistant wood adhesives. For precise performance values and approvals,

always consult the latest Soudal technical datasheet and Safety Data Sheet (SDS).

- Adhesive type: One‑component, moisture‑curing polyurethane wood adhesive.

- Classification: D4 water resistance to EN 204 – suitable for high‑moisture interior and exterior applications when correctly protected.

- Bonded materials: Softwood, hardwood, many engineered woods (MDF, chipboard, plywood, OSB), and some non‑porous materials (after testing), such as certain metals and rigid foams.

- Water resistance: High; designed for joints exposed to frequent moisture or weather when adequately protected by coatings and design.

- Heat & creep resistance: Good resistance to elevated temperatures and creep in typical D4 applications (often also tested to relevant heat resistance standards such as EN 14257 / WATT 91 – check current datasheet).

- Colour: Typically light to medium brown bond line once cured (may vary by batch – check label).

- Foaming behaviour: Expands slightly during cure, giving a gap‑filling effect for minor joint irregularities.

- Open time & press time: Dependent on temperature, humidity and application rate (see product datasheet for exact figures).

- Service conditions: Suitable for interior and exterior conditions within the D4 classification; follow local Building Regulations and engineering guidance for structural use.

- Storage: Store in the original, tightly closed container in a cool, dry place. Protect from frost and high temperatures. PU adhesives are sensitive to moisture – reseal immediately after use.

- Safety: Contains isocyanate‑based components; use in a well‑ventilated area and wear suitable PPE (gloves, eye protection). Follow SDS and label instructions.

Soudal D4 PU Wood Glue Features & Customer Benefits

- D4‑rated waterproof performance

Certified to EN 204 D4, giving you confidence on high‑moisture indoor joints

and weather‑exposed exterior joinery when correctly detailed and protected. - Excellent for C16/C24 structural timber joints

When specified by the structural designer, Soudal D4 PU Wood Glue is ideal for

bonding C16 and C24 graded structural timbers in conjunction with mechanical

fixings, helping to create robust, rigid assemblies. - Gap‑filling for imperfect joints

Slight foaming action helps bridge small gaps and surface irregularities,

particularly useful for site‑cut joints that are not perfectly machined. - One‑component, ready‑to‑use

No mixing required. Simply apply from the bottle, clamp and allow to cure –

saving time and reducing waste in both workshop and on‑site environments. - Versatile bonding across multiple materials

Ideal for hardwood, softwood, MDF, chipboard, plywood and some non‑porous

substrates, reducing the number of different adhesives you need to stock.

Frequently Asked Questions – Soudal D4 PU Wood Glue

1. What is the difference between Soudal D4 PU Wood Glue and a standard PVA wood glue?

Standard PVA wood glues are typically classified D1–D3 and are best suited to

interior applications with limited moisture exposure. Soudal D4 PU Wood Glue

is a polyurethane adhesive with D4 water resistance (EN 204), meaning it can be

used for:

- High‑moisture interior areas (e.g. kitchens, bathrooms, wetrooms), and

- Exterior applications when joints are properly detailed and protected.

It also offers higher strength, better heat resistance and a gap‑filling,

foaming action compared to most PVAs, making it far more suitable for demanding

joinery and structural work.

2. Can I use Soudal D4 PU Wood Glue for exterior doors, windows and garden furniture?

Yes. Soudal D4 PU Wood Glue is ideal for exterior joinery such as doors,

windows, gates and garden furniture, provided:

- The joint design follows good exterior joinery practice, avoiding standing water and trapped moisture.

- The assembled product is properly primed, painted or otherwise protected from direct weathering in line with joinery standards.

The D4 classification ensures the bond line itself has a high level of water

resistance, but the overall durability still depends on design, coatings and maintenance.

3. Is Soudal D4 PU Wood Glue suitable for structural timber applications?

Soudal D4 PU Wood Glue develops a very strong bond and can be used in many

structural timber applications when:

- The use of an EN 204 D4 polyurethane adhesive is permitted by the structural engineer or system designer.

- It is used in combination with appropriate mechanical fixings (screws, bolts, nails, plates, etc.) as required by design and Building Regulations.

Always follow the project specification, engineering calculations and local

Building Regulations. Do not assume any adhesive alone can replace required

mechanical fixings or structural connectors.

4. How long do I need to clamp the joint when using Soudal D4 PU Wood Glue?

Clamping time depends on:

- Temperature and humidity,

- The species and moisture content of the timber,

- The thickness of the adhesive layer and joint design.

As a general guide, initial handling strength is often achieved within 30–60 minutes

in favourable conditions, but full cure usually requires around 24 hours.

Always refer to the product datasheet for recommended clamping/press times for

your conditions and do not stress the joint until adequate strength has developed.

5. Can I use Soudal D4 PU Wood Glue on wet or damp timber?

Soudal D4 PU Wood Glue is a moisture‑curing adhesive and does require some

moisture to cure. However:

- Very wet timber (e.g. surface water, high moisture content) can cause over‑foaming, reduced strength and poor adhesion.

- Best results are obtained on timber at normal joinery moisture contents (typically 8–18%, check relevant standards).

- For very dry timber, lightly dampening one surface with a water mist is usually sufficient.

Do not use on saturated or frozen timber. Allow excessively wet wood to dry to

an acceptable moisture content before bonding.

6. Common Uses & How to Use Soudal D4 PU Wood Glue

Common Uses:

- Bonding C16/C24 structural timbers in conjunction with mechanical fixings.

- Manufacture and repair of external doors, windows and frames.

- Assembly of kitchen and bathroom furniture, worktops and cabinets.

- Construction and repair of stairs, handrails and balustrades.

- Exterior timber projects such as gates, pergolas, sheds and garden furniture.

How to Use – Step‑by‑Step:

- Check the wood is sound, clean and within the appropriate moisture range for the application.

- Plane or sand mating surfaces to achieve a good fit with minimal gaps.

- (Optional) Lightly mist one surface with clean water if the timber is very dry.

- Apply Soudal D4 PU Wood Glue in a continuous bead or thin, even film to one of the bonding faces.

- Bring the parts together within the stated open time, align accurately and apply uniform clamping pressure across the joint.

- Maintain clamping for the minimum press time shown on the datasheet, adjusting for temperature and humidity.

- Allow adhesive squeeze‑out to foam and cure; then trim or sand away excess once fully set.

- After full cure (typically 24 hours), the assembly can be machined, sanded, finished and, where applicable, coated for exterior exposure.

| Size | 5 Minute 290ml Tube, 30 Minute 290ml Tube, 5 Minute 750Gr Tub, 30 Minute 750Gr Tub |

|---|

Add a review

You must be logged in to post a review.

Shipping Policy

At Always First 4 Fixings, we know that your projects rely on fast, dependable delivery. That’s why we offer flexible UK shipping options designed for tradespeople and businesses:

Fast Dispatch: Orders are processed and dispatched within 24 hours on working days.

Free shipping on all orders over £60 (UK mainland).

Express options available to keep your jobs moving.

Click & Collect: Order online and pick up at your convenience (if applicable).

Reliable Couriers: We use trusted UK carriers to ensure your fixings and fasteners arrive on time.

You’ll receive tracking details as soon as your order leaves our warehouse. Delivery times may vary depending on location and availability, but we work hard to get your order to you as quickly as possible.

At Always First 4 Fixings, we know that your projects rely on fast, dependable delivery. That’s why we offer flexible UK shipping options designed for tradespeople and businesses:

Fast Dispatch: Orders are processed and dispatched within 24 hours on working days.

Free shipping on all orders over £60 (UK mainland).

Express options available to keep your jobs moving.

Click & Collect: Order online and pick up at your convenience (if applicable).

Reliable Couriers: We use trusted UK carriers to ensure your fixings and fasteners arrive on time.

You’ll receive tracking details as soon as your order leaves our warehouse. Delivery times may vary depending on location and availability, but we work hard to get your order to you as quickly as possible.

Reviews

There are no reviews yet.