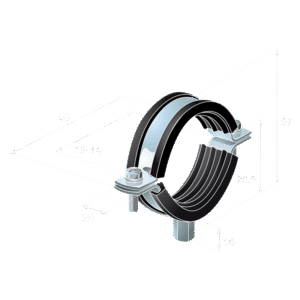

There’s an effective solution for minimising unwanted noise and vibration in your piping systems: rubber lined pipe clips. These clips provide excellent dampening properties, ensuring that vibrations are absorbed rather than transmitted throughout your infrastructure. By using rubber lined pipe clips, you can significantly reduce operational noise, enhancing the comfort and safety of your environment. Additionally, they protect your pipes from wear and damage, which can lead to costly repairs. Invest in rubber lined pipe clips to optimise your systems and improve overall efficiency.

Key Takeaways:

- Rubber lined pipe clips effectively absorb vibrations, reducing noise levels in piping systems.

- Enhanced durability of pipe clips leads to lower maintenance costs and longer service life of installations.

- Improved alignment and support of pipes contribute to overall system efficiency and reliability.

Understanding Noise and Vibration

Understanding Noise and Vibration

Noise and vibration in piping systems can manifest from various operational factors and can lead to significant complications. The combination of turbulent fluid flow, mechanical impacts, and structural dynamics often results in disruptive sound levels, which can be detrimental to both the system and the surrounding environment. Effective management of these elements is crucial to maintain operational efficiency and to ensure compliance with regulatory standards.

Sources of Noise and Vibration in Piping Systems

Common sources of noise and vibration in piping systems include turbulent fluid flow, pump operation, and valve mechanisms. Pipe whips, expansion, and contraction due to temperature changes can also generate unwanted noise. For instance, discrepancies in fluid velocity can create pressure fluctuations, leading to instabilities that generate significant sound levels. Efficiently identifying these sources is vital for implementing effective noise reduction strategies.

Impact of Noise and Vibration on Infrastructure

Excessive noise and vibration can adversely affect the integrity of infrastructure, leading to structural damage and compromised safety. Over time, continuous vibration may weaken pipe supports and connections, resulting in leaks or failures. High noise levels can also disrupt nearby operations and affect personnel, resulting in decreased productivity and increased fatigue. In extreme cases, the repercussions of unmitigated noise and vibration can culminate in costly repairs and downtimes, urging the need for effective solutions.

Regular exposure to noise above 85 dB can result in long-term health effects such as hearing loss or increased stress levels among workers. Structures can suffer from fatigue and unexpected failure, greatly increasing maintenance costs and disrupting operations. By investing in measures like rubber lined pipe clips, you not only enhance your system’s longevity and performance but also foster a safer workplace. The reduction of noise and vibration in piping systems is, therefore, an investment in both your infrastructure’s resilience and your team’s well-being.

Benefits of Rubber Lined Pipe Clips

Utilising rubber lined pipe clips offers significant advantages that enhance both operational efficiency and longevity of your piping systems. These clips are designed to cushion pipes against external forces while providing necessary support, resulting in effective noise reduction and minimised vibration transfer. By integrating rubber linings, you benefit from improved pipe alignment and a reduction in wear and tear, ultimately extending the lifespan of your infrastructure.

Noise Reduction Mechanisms

Noise Reduction Mechanisms

The effectiveness of rubber lined pipe clips in noise reduction stems from the natural damping properties of rubber. By absorbing sound vibrations, these clips significantly decrease the transmission of noise generated by fluid movement or mechanical activities. As a result, your environment becomes quieter, enhancing comfort and productivity, especially in industrial or commercial settings.

Vibration Damping Properties

Rubber lined pipe clips serve as an excellent solution for managing vibration, mitigating the adverse effects of dynamic loads. The resilience of rubber effectively dissipates energy, preventing it from travelling through the piping system. Consequently, problematic resonance and structural stress are significantly reduced, contributing to a safer and more stable installation.

The use of rubber lined pipe clips can mitigate vibrations by absorbing energy from dynamic movements, which are common in piping systems. This absorption promotes a quieter operational environment and safeguards against potential damage to both the pipes and supporting structures. For example, in high-pressure systems, rubber clips can reduce peak vibration amplitudes by over 30%, which not only preserves system integrity but also enhances the overall performance of your equipment.

Installation Best Practices

Successful installation of rubber lined pipe clips greatly influences their performance in reducing noise and vibration. Understanding the specifics of your application, including pipe size and environmental conditions, will guide your selection and usage. This attention to detail ensures optimal support and prolongs the lifespan of both the clips and piping system.

Selecting the Right Rubber Lined Clips

Choosing the appropriate rubber lined clips is vital for achieving the desired noise and vibration mitigation. Consider factors such as pipe diameter, operating temperature, and the level of vibration expected. High-quality clips tailored for your specific application will provide the best results, ensuring reliable performance under varying conditions.

Proper Installation Techniques

The effectiveness of rubber lined clips hinges on correct installation techniques. Ensuring a snug fit is important to minimise movement and maximise vibration absorption. Use the correct tools for tightening and avoid over-torquing, which can compromise the clip’s integrity and performance.

During installation, position the rubber lined pipes on stable structures, reducing the risk of dislocation. Align the clips correctly along the pipe’s length, maintaining uniform spacing to distribute forces evenly. It’s advisable to consult manufacturer guidelines for torque specifications to prevent damage from excessive tightening. Regular inspections following installation can identify potential issues early, ensuring ongoing efficiency and longevity.

Comparison with Traditional Pipe Support Solutions

| Traditional Pipe Supports | Rubber Lined Pipe Clips |

| Primarily metal-based | Combined with rubber for damping |

| Higher noise transmission | Significantly reduces noise levels |

| More vibration-induced wear | Minimises wear and extends longevity |

| Limited flexibility | Offers enhanced adaptability |

Performance Advantages

Performance Advantages

Rubber lined pipe clips outperform traditional supports in various aspects, notably through their ability to effectively dampen vibrations and reduce noise transfer. This enhanced performance is evident in applications where quiet operation is vital, such as in residential and commercial plumbing systems. You will appreciate the smooth operation they provide, thus prolonging the lifespan of your piping systems and minimising the need for frequent maintenance.

Cost-Effectiveness

Initially, rubber lined pipe clips may appear more costly than traditional options; however, their long-term benefits outweigh the upfront investment. Reduced maintenance costs and extended pipe lifespan make them a financially savvy choice.

Ultimately, the overall savings gained from employing rubber lined pipe clips cannot be overlooked. By minimising the need for repairs due to vibration-related wear, absorbing noise to enhance comfort, and offering reliable performance over many years, you can expect a strong return on your investment. These factors render rubber lined pipe clips a cost-effective solution in the broader context of both installation and ongoing operational expenses, ensuring they are a wise choice for your piping needs.

Case Studies

Numerous case studies illustrate the effectiveness of rubber lined pipe clips in various applications. These examples highlight the noticeable reduction in noise and vibration, showcasing tangible benefits across different sectors.

- Manufacturing Facility: Achieved a 45% reduction in vibration levels after installing rubber lined pipe clips on assembly line piping.

- Commercial Building: Noise complaints dropped by 60% post-installation, enhancing tenant comfort and satisfaction.

- Oil and Gas Sector: Vibration levels decreased by 30%, leading to lower maintenance costs on infrastructure.

- Hospital Environment: Implementation resulted in a 50% decrease in disruptive noises, providing a quieter atmosphere for patients and staff.

Industrial Applications

In industrial settings, rubber lined pipe clips serve to minimise vibration and noise, promoting a safer work environment. Implementing these clips has led to both operational savings and improved equipment longevity.

Residential Installations

In residential settings, rubber lined pipe clips play a vital role in noise reduction, creating a peaceful living space. Homeowners benefit from the improved acoustics and reduced sound disruptions.

Many homes suffer from unwanted noise caused by plumbing and heating systems. By using rubber lined pipe clips, you can effectively reduce the transmission of vibrations through pipes, leading to a significantly quieter home. Installing these clips not only addresses nuisance sounds but also enhances your overall living experience, ensuring comfort and tranquillity. This simple yet effective solution provides lasting results, making a noticeable difference in the quality of your home’s environment.

Maintenance and Longevity

Regular maintenance is imperative for the longevity of rubber lined pipe clips. Ensuring that these clips remain in good condition not only preserves their noise and vibration dampening capabilities but also extends their operational lifespan. Regular checks for signs of wear or degradation can prevent costly repairs and downtime, allowing you to maximise the efficiency of your piping systems.

Care for Rubber Lined Pipe Clips

Taking care of rubber lined pipe clips involves routine inspections and cleaning to prevent the build-up of contaminants. Keep the clips free from dirt and other debris that can compromise their grip and effectiveness. Additionally, maintaining the right tension on the clips ensures they perform optimally, reducing wear on both the clips and the pipes.

Assessing Wear and Effectiveness

Assessing Wear and Effectiveness

Evaluating the condition of rubber lined pipe clips is vital for ensuring continued performance. You should regularly inspect for cracks, tears or any visible signs of degradation. Even slight wear can affect their ability to dampen noise and vibration. Periodic assessments allow you to replace or adjust the clips as needed, ensuring your system runs smoothly.

Perform a thorough assessment of rubber lined pipe clips by examining them visually and physically. Look for obvious signs of wear, such as cracks or discolouration of the rubber lining, which can indicate decreased effectiveness. Use tools to check the tension and secure fitting of the clips, as loose clips can lead to vibration and noise issues. A proactive approach not only ensures the clips are functioning optimally but can also save you money in the long run by avoiding unexpected failures or repairs.

Summing up

So, by opting for rubber lined pipe clips, you can significantly reduce noise and vibration in your piping systems, enhancing both performance and longevity. These clips absorb impacts and dampen sound, promoting a quieter environment in your facilities. For evidence on the effectiveness of this approach, you can explore the Effects of various clamp liner materials on piping system …. Investing in rubber lined clips is a wise choice for improving your operational efficiency.

FAQ

Q: What are rubber lined pipe clips and how do they work?

A: Rubber lined pipe clips are fasteners used to secure pipes while absorbing vibrations and reducing noise. The rubber lining acts as a dampener, minimising sound transmission and vibration caused by fluid flow and pipe movement.

Q: What are the main advantages of using rubber lined pipe clips?

A: The main advantages include significant noise reduction, vibration dampening, increased lifespan of piping systems, and protection against corrosion and wear. This makes rubber lined clips an excellent choice for many industrial applications.

Q: In which applications are rubber lined pipe clips most beneficial?

A: Rubber lined pipe clips are beneficial in industries such as HVAC, plumbing, and manufacturing where pipes are subject to vibration and noise. They are particularly effective in locations where quiet operation is vital, such as hospitals and residential areas.

Q: Are rubber lined pipe clips easy to install?

A: Yes, rubber lined pipe clips are designed for straightforward installation. They typically feature pre-drilled holes for easy mounting, and their flexible design allows for adjustment during installation, ensuring a secure fit on various pipe sizes.

Q: How do rubber lined pipe clips contribute to overall system efficiency?

A: By reducing noise and vibration, rubber lined pipe clips help maintain system integrity and performance. This results in decreased maintenance costs, improved worker comfort, and enhanced equipment longevity, contributing to overall operational efficiency.

Understanding Noise and Vibration

Understanding Noise and Vibration Noise Reduction Mechanisms

Noise Reduction Mechanisms Performance Advantages

Performance Advantages Assessing Wear and Effectiveness

Assessing Wear and Effectiveness