Over the course of any woodworking project, selecting the right wood screws can significantly impact both the durability and appearance of your finished work. You need to understand the different types, sizes, and materials available to ensure optimal performance. This guide will help you navigate these options, highlighting the most effective choices for your specific needs. By making informed decisions, you can enhance the success of your project and achieve results you can be proud of.

Key Takeaways:

- Select the appropriate screw type based on the material being used, such as softwood, hardwood, or composite.

- Pay attention to screw length and diameter to ensure a secure fit and optimal holding strength.

- Consider the finish of the screws, such as galvanised or stainless steel, to enhance durability and resistance to corrosion.

Understanding Wood Screws

Understanding Wood Screws

Wood screws are crucial fasteners designed to join wooden materials securely. Their unique thread pattern and tip design facilitate easy driving into wood, preventing splitting and ensuring a solid hold. You can find wood screws in various lengths and diameters, catering to different project requirements.

Types of Wood Screws

Various types of wood screws exist, each tailored for specific applications:

- Sheet metal screws

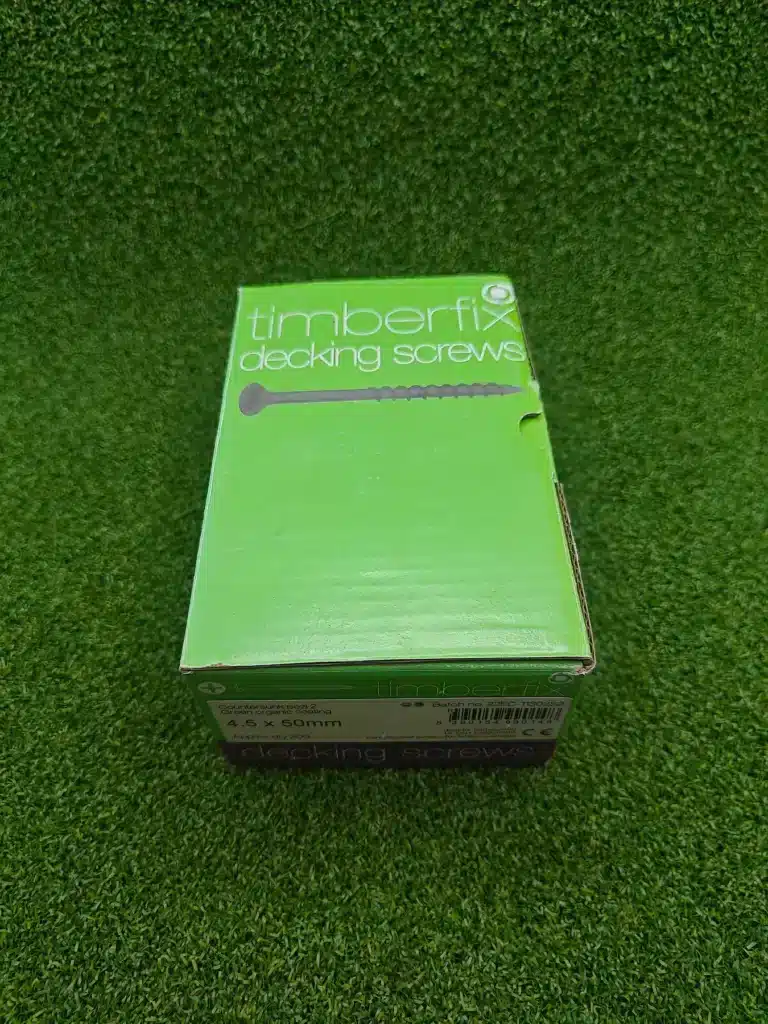

- Deck screws

- Wood decking screws

- Drywall screws

- Lag screws

Thou should select the right type based on your material and intended use.

| Type | Application |

| Sheet metal screws | Joining metal to wood |

| Deck screws | Outdoor decking projects |

| Wood decking screws | Securely fastening wood decking |

| Drywall screws | Attaching drywall to wooden frames |

| Lag screws | Heavy-duty fastening |

Common Materials Used

Wood screws are typically made from three main materials: stainless steel, carbon steel, and brass. Each material offers distinct advantages that suit various environments and applications.

Stainless steel is highly resistant to rust, making it an excellent choice for outdoor projects or areas exposed to moisture. Carbon steel provides strength and durability, often used in construction, but requires coatings to prevent corrosion. Brass screws are more decorative and resistant to corrosion, ideal for visible applications like cabinetry. Selecting the right material ensures your fasteners will endure the test of time and environmental conditions, leading to a more successful project outcome.

Key Factors to Consider

Selecting the right wood screws for your project relies on several key factors that can influence the overall strength and durability of your assembly. Understanding these aspects will enhance the outcome of your work, contributing to both functionality and aesthetics. Consider the following:

- Screw length

- Diameter

- Thread type

- Material

- Coating

Any oversight in these elements can lead to structural failures or compromised finishes.

Screw Length and Diameter

Screw Length and Diameter

The length and diameter of your screws directly affect their holding power. A general rule is to choose screws that penetrate at least half the thickness of the material being joined. For instance, if you are fastening a 19mm thick board, select screws that are at least 25mm long. Diameter is equally important; thicker screws offer enhanced strength but require pre-drilling in some materials to avoid splitting.

Thread Type and Design

Different thread types serve specific purposes. Coarse threads are better for softwood, providing superior grip, while fine threads are ideal for hardwood or when high precision is required. Choose screws designed for specific applications, such as drywall screws or decking screws, which often feature unique thread designs for improved performance.

Thread design significantly impacts how a screw engages with the material. Coarse threads, for instance, have deeper grooves which enhance pull-out resistance in softer woods, while fine threads provide stability in denser materials. Additionally, some screws incorporate features like self-drilling points, which eliminate the need for pre-drilling and allow for faster assembly, making them ideal for dynamic environments where speed and efficiency are crucial.

Step-by-Step Guide to Choosing Wood Screws

| Key Steps | Description |

|---|---|

| Assessing Your Project Needs | Evaluate the specifics of your project to determine screw type, length, and material requirements. |

| Selecting the Right Screw | Choose screws based on your material, application, and the desired strength of the joint. |

Assessing Your Project Needs

Understanding your project’s requirements is imperative. Consider factors such as the type of wood, the thickness of the materials, and whether the screws will be exposed to outdoor elements. For instance, when working with softwood versus hardwood, different screw types may be necessary to achieve optimal results in terms of strength and holding power.

Selecting the Right Screw

Choosing the appropriate screw involves considering the screw’s diameter, length, and head type. Select a screw that complements your wood, ensuring it penetrates adequately without splitting the material. For outdoor projects, stainless steel or coated screws provide enhanced corrosion resistance, ensuring durability in various conditions.

A deeper understanding of screw classifications aids in making informed decisions. For example, wood screws typically come with various head styles, like flat, round, or pan, which affect both appearance and functionality. Additionally, the screw’s thread type matters; coarse threads are better suited for softwoods, while fine threads offer superior grip in hardwoods. Choosing the right wood screw boosts the longevity and stability of your project, ultimately enhancing its overall quality.

Tips for Optimal Performance

Tips for Optimal Performance

To ensure the best results with your wood screws, consider these tips for optimal performance. Always select screws that match the thickness of your material, as this helps in achieving maximum strength. Maintain a consistent driving speed to prevent stripping the screw head. Use a suitable driver bit and apply sufficient torque without overtightening. Additionally, store screws in a dry place to avoid moisture damage. Thou shall ensure proper alignment of screws for a neat finish and enhanced durability.

Pre-Drilling and Counterboring

Pre-drilling pilot holes and counterboring can significantly improve the installation of your wood screws. When screwing into dense or hardwoods, pre-drilling reduces the risk of splitting the material. Counterboring allows the screw head to sit flush with or below the wood surface, creating a professional appearance and preventing snagging. Adjust your drill bit size according to the screw diameter to maintain effective grip while avoiding unnecessary strain.

Avoiding Common Mistakes

Many users fall into traps that affect screw performance. Utilising incorrect screw lengths can lead to inadequate holding power or damage to the wood. Mixing different materials can cause corrosion, weakening the joint over time. Failing to account for wood expansion and contraction often results in stripped screws. Additionally, neglecting to use lubricant for longer screws can increase resistance and complicate installation. Awareness of these pitfalls ensures your project remains sturdy and reliable.

Avoiding common mistakes is crucial for successful projects. Using the wrong type of wood screw can lead to compromised structural integrity; for instance, using drywall screws in wood applications can diminish strength. An example is when insufficient pilot holes cause wood to split, resulting in an unsightly and weak joint. Paying attention to the specific requirements of your materials and following best practices, such as selecting the right screw type and length, guarantees optimal results. Thou can thus prevent frustrating setbacks and ensure your work withstands the test of time.

Pros and Cons of Different Wood Screws

| Pros | Cons |

|---|---|

| Strong holding power | Can split the wood if over-tightened |

| Range of sizes and types available | Specific types may require pre-drilling |

| Aesthetic options with decorative heads | More expensive than other fasteners |

| Easily removable, allowing for adjustments | Corrosion can be an issue without proper coating |

| Suitable for a variety of wood types | Length selection is critical for effectiveness |

Advantages of Using Wood Screws

Advantages of Using Wood Screws

Wood screws excel in their ability to provide a reliable connection between wooden components, thanks to their sharp threads that grip tightly. This strength ensures structural stability in your projects and makes them particularly effective for load-bearing applications. Their versatility allows you to use them in various wood types, and decorative options enhance the visual appeal of your finished work.

Limitations and Drawbacks

While wood screws offer numerous advantages, they are not without limitations. Improper selection can lead to issues like splitting wood or insufficient holding power. Without proper care, wooden screws can corrode, especially in moist environments, leading to long-term structural failures. Furthermore, choosing the correct length and gauge is crucial for achieving optimal results, which may complicate the decision-making process.

Splitting wood is a common concern when using wood screws, particularly if you’re working with hardwoods or dense materials. If the screws are too long or driven too forcefully, they can compromise the integrity of your project. Furthermore, in environments prone to moisture, screws without the correct protective coating may suffer from rust, weakening their hold over time. Ensuring you account for these factors significantly impacts the durability and longevity of your projects.

Summing up

Hence, selecting the right wood screws for your next project is crucial to ensure optimal results and durability. By understanding screw types, materials, lengths, and diameters, you can make informed decisions that suit your needs perfectly. Always consider the specific requirements of your wood and the intended application to ensure a secure fit. With this guide, you can approach your projects with confidence, knowing you’ve chosen the best screws for the job.

FAQ

Q: What types of wood screws are available?

A: There are several types of wood screws, including regular wood screws, deck screws, and drywall screws. Each type is designed for specific applications and varying materials.

Q: How do I determine the right size of wood screw for my project?

A: To determine the right size, consider the thickness of the materials being joined and the screw length required to provide adequate grip without excessive protrusion.

Q: What materials are wood screws typically made from?

A: Wood screws are commonly made from steel, stainless steel, brass, or bronze. The choice of material affects corrosion resistance and strength, making it imperative to select the right one for your project.

Q: Should I use coated or untreated wood screws?

A: It is advisable to use coated screws for outdoor projects or in moist environments, as the coating provides additional protection against rust and corrosion compared to untreated screws.

Q: What is the function of the screw’s thread design?

A: The thread design influences how well the screw holds in the wood. Coarse threads provide better grip in softwoods, while fine threads are more effective in hardwoods. Select the thread design based on the type of wood you are working with.

Understanding Wood Screws

Understanding Wood Screws Screw Length and Diameter

Screw Length and Diameter Tips for Optimal Performance

Tips for Optimal Performance Advantages of Using Wood Screws

Advantages of Using Wood Screws