Galvanised Banding | Perforated Galvanised Fixing Strap

- Highly versatile – suitable for strapping, hanging, bracing and general fixing in many applications.

- Galvanised steel – zinc coating provides corrosion resistance for internal and many external uses.

- Pre‑punched holes – evenly spaced holes accept screws, bolts or nails for easy installation.

- Supplied in coil – cut to length on site, minimising waste and maximising flexibility.

- Easy to form – can be bent or wrapped around services and structures as required.

Free shipping on orders over £60

- No-Risk Money Back Guarantee!

- No Hassle Refunds

- Secure Payments

Galvanised Banding Builders All-Round Fixing Strap

Galvanised Banding is a versatile, perforated steel strapping used for fixing, bracing and

supporting a wide range of building and mechanical services. Supplied in convenient coils and

featuring pre‑punched holes, this zinc‑coated banding is ideal for hanging, securing and

restraining pipework, ducting, cable trays, timber members and general construction elements.

Galvanised Banding (also known as galvanised strapping or fixing band) is manufactured from mild

steel strip with a protective zinc coating and regular pre‑punched holes. It provides a simple,

adjustable fixing method where rigid brackets are not practical or where variable positioning is

required.

Typically supplied in rolls, the banding can be cut to the required length using tin snips or

appropriate cutters, then formed around or along the item to be supported. Fixings such as screws,

coach screws, nails or bolts can be passed through the pre‑punched holes into the supporting

structure, allowing secure attachment in a wide variety of scenarios.

Commonly used by plumbers, heating engineers, electricians, HVAC installers and general builders,

Galvanised Banding is suitable for domestic, commercial and light industrial applications where a

strong, adjustable and corrosion‑resistant fixing is required.

Typical Use Cases

- Supporting and restraining pipework and ducting to walls, ceilings and structural members.

- Hanging cable trays, trunking and conduits.

- Bracing and tying lightweight timber framing, fencing and roof timbers.

- Securing tanks, cylinders and equipment to walls or floors (within rated load limits).

- General strapping, fixing and temporary supports in construction and maintenance work.

Installation & Usage Tips

- Cut to length: Measure and cut the banding with suitable metal snips, leaving enough length for secure fixings.

- Use appropriate fixings: Select screws, bolts or nails of suitable size and corrosion resistance for the substrate.

- Avoid sharp bends: Form smooth curves rather than sharp kinks to maintain strength.

- Do not overload: Check typical load capacities (if provided) and avoid using banding for heavy structural loads.

- Protect cut edges: Treat cut ends with zinc‑rich or suitable protective coating if used in exposed environments.

Technical Information (Typical)

Specification varies by product width, thickness and coil length; always refer to packaging or

data sheet for the specific Galvanised Banding you are using. Typical characteristics include:

- Type: Perforated galvanised steel banding / fixing strap.

- Material: Mild steel strip with galvanised (zinc) coating.

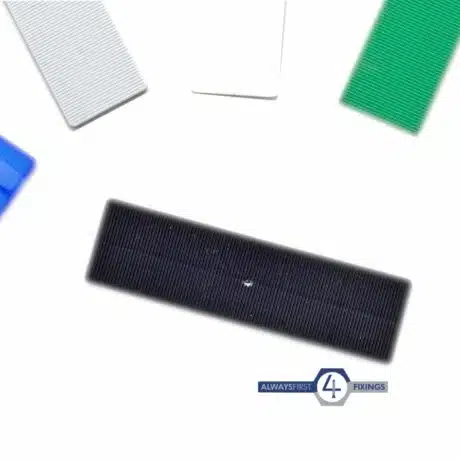

- Widths: Commonly available in widths such as 12mm, 18mm, 25mm, etc. (confirm size).

- Thickness: Varies by product – typically light to medium gauge for support and restraint (check data sheet).

- Holes: Regularly spaced pre‑punched holes for screws/bolts/nails (hole size and pitch per manufacturer).

- Coil length: Supplied in rolls (e.g. 10m, 25m or 50m – confirm length).

- Finish: Galvanised for corrosion resistance in normal indoor and many outdoor environments.

- Applications: Non‑structural support and restraint of building services, light framing and general fixings.

For detailed dimensions, hole patterns and any load guidance, refer to the manufacturer’s

technical information for the chosen Galvanised Banding product.

Key Features

- Perforated for easy fixing – no need to drill; simply fix through existing holes.

- Adjustable on site – cut, bend and position exactly where needed.

- Corrosion‑resistant galvanised coating – suitable for a wide range of environments.

- Multi‑trade solution – ideal for plumbing, electrical, HVAC and general building work.

- Economical – one product solves many light‑duty support and restraint needs.

Frequently Asked Questions (FAQs)

1. What is Galvanised Banding used for?

It is used for strapping, supporting and bracing items such as pipework, ducting, cable

management systems, light timber framing and other components where a flexible, adjustable

fixing is required.

2. Can I use Galvanised Banding outdoors?

Yes, the galvanised coating offers corrosion resistance suitable for internal and many

external applications. For highly aggressive or coastal environments, consider heavier

galvanising or stainless solutions and always follow manufacturer guidance.

3. How do I cut Galvanised Banding?

Use suitable metal‑cutting snips or shears. After cutting, deburr sharp edges and, for

external use, protect cut ends with a zinc‑rich or similar protective coating.

4. What fixings should I use with it?

Use screws, bolts or nails that match the hole size and are appropriate for the supporting

material (e.g. masonry screws, timber screws) and exposure conditions. Corrosion‑resistant

fixings are recommended with galvanised banding.

5. Is Galvanised Banding suitable for heavy structural loads?

It is generally intended for light to medium‑duty support and restraint, not for primary

structural connections. For structural or safety‑critical applications, use purpose‑designed

structural connectors with published load ratings and consult an engineer where necessary.

Common Uses / How to Use

To get the best from Galvanised Banding:

- Measure the length required to wrap or span between fixing points.

- Cut the banding to length using appropriate snips or cutters.

- Form the banding around the pipe, duct, cable tray or timber as needed.

- Align pre‑punched holes with the substrate and secure using suitable screws, bolts or nails.

- Ensure the band is tensioned and supported adequately, using multiple runs or fixings where necessary.

Shipping Policy

At Always First 4 Fixings, we know that your projects rely on fast, dependable delivery. That’s why we offer flexible UK shipping options designed for tradespeople and businesses:

Fast Dispatch: Orders are processed and dispatched within 24 hours on working days.

Free shipping on all orders over £60 (UK mainland).

Express options available to keep your jobs moving.

Click & Collect: Order online and pick up at your convenience (if applicable).

Reliable Couriers: We use trusted UK carriers to ensure your fixings and fasteners arrive on time.

You’ll receive tracking details as soon as your order leaves our warehouse. Delivery times may vary depending on location and availability, but we work hard to get your order to you as quickly as possible.

At Always First 4 Fixings, we know that your projects rely on fast, dependable delivery. That’s why we offer flexible UK shipping options designed for tradespeople and businesses:

Fast Dispatch: Orders are processed and dispatched within 24 hours on working days.

Free shipping on all orders over £60 (UK mainland).

Express options available to keep your jobs moving.

Click & Collect: Order online and pick up at your convenience (if applicable).

Reliable Couriers: We use trusted UK carriers to ensure your fixings and fasteners arrive on time.

You’ll receive tracking details as soon as your order leaves our warehouse. Delivery times may vary depending on location and availability, but we work hard to get your order to you as quickly as possible.