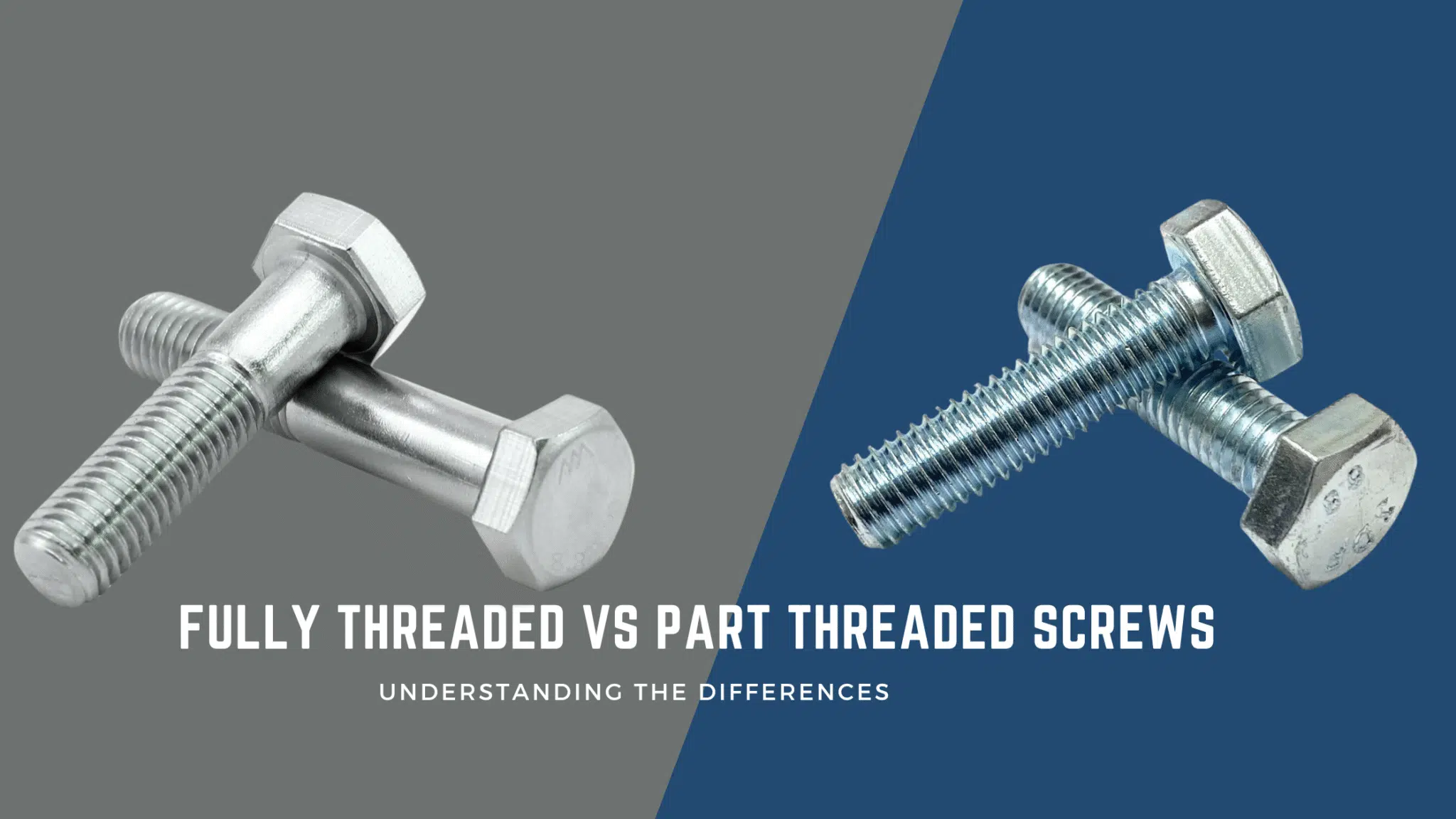

It’s vital to know the differences between fully threaded and part threaded screws when selecting the right fastener for your projects. Fully threaded screws have threads that run the entire length, providing strong holding power in materials like wood and metal. In contrast, part threaded screws feature a smooth shank that aids in alignment and reduces friction, making them ideal for specific applications. Understanding these distinctions will enhance your ability to choose the best fastening solution, ensuring stability and durability in your work.

Fully Threaded vs Part Threaded Screws Key Takeaways:

- Fully threaded screws feature threads that extend along the entire length of the shank, which allows for greater grip and tension when fastening materials together.

- Part threaded screws have a smooth shank portion beneath the head; this is beneficial for applications where a combination of clamping force and a pilot hole is useful.

- Choosing between fully threaded and part threaded screws depends on material type, joint configuration, and the desired strength of the assembly.

- Fully threaded screws are ideal for thin materials or situations where a tight fit is necessary, while part threaded screws suit thicker materials or where softer surfaces need reinforcing.

- Understanding the differences in thread design can significantly affect the strength and durability of the fastening, ensuring optimal performance in various applications.

Definition of Fully Threaded Screws

Definition of Part Threaded Screws

Applications of Fully Threaded Screws

Assuming you are working on a project that demands maximum grip and support, fully threaded screws are ideal for your needs. These screws offer a continuous thread along the entire length, which ensures a strong connection in materials where full engagement is necessary, such as in timber and drywall applications. Their ability to provide uniform holding power makes them suitable for both structural and non-structural applications. Whether you’re building a deck or securing heavy machinery, using fully threaded screws can enhance the stability and durability of your work.

Applications of Part Threaded Screws

Clearly, part threaded screws are ideal for applications where you require a strong grip in softer materials, such as wood or plastic. The unthreaded shank allows for compression of materials and can help prevent splitting of the wood when driving the screw in. Use these screws in cabinetry, furniture assembly, or applications where you need pivot points or securing movement. Their design provides the best of both worlds, offering strength where it matters and flexibility in securing components.

Advantages of Fully Threaded Screws

Advantages of Part Threaded Screws

Summing up

Conclusively, understanding the differences between fully threaded and part threaded screws empowers you to select the right type for your projects. Fully threaded screws provide consistent gripping surface and are ideal for applications requiring depth, while part threaded screws offer better support for structural components where the shank length is necessary to reduce stress. By aligning your choice with the specific requirements of your tasks, you ensure optimal performance and longevity in your fastening solutions.

Fully Threaded vs Part Threaded Screws FAQ

Q: What is the main difference between fully threaded and part threaded screws?

A: The primary distinction lies in the threading of the screw. Fully threaded screws have threads running the entire length of the shank, ensuring a tight grip throughout their entire length. This makes them suitable for applications requiring maximum holding power in a material. Conversely, part threaded screws feature smooth shanks beneath the head, allowing for easier insertion and a more controlled clamping force. The choice between the two often depends on the specific requirements of the project, such as the materials being joined and the desired strength of the connection.

Q: When should I opt for fully threaded screws instead of part threaded screws?

A: Fully threaded screws are ideal for fastening materials where maximum pull-out resistance is required, such as when working with softer woods or in applications subjected to movement or stress. They provide a uniform grip along the entire length of the screw, making them suitable for thicker or denser materials. If you are working on projects that require deep penetration or need the screw to engage more material for strength, fully threaded screws should be your choice.

Q: Are there any specific scenarios where part threaded screws are more advantageous?

A: Yes, part threaded screws are often advantageous in applications where alignment is critical. The smooth shank allows for easier adjustment and movement of materials before final tightening, which can be important in furniture assembly or when securing frames. Additionally, part threaded screws can reduce the risk of splitting in timber, making them a better option in situations where joining different thicknesses of materials or where handling delicate components is involved.