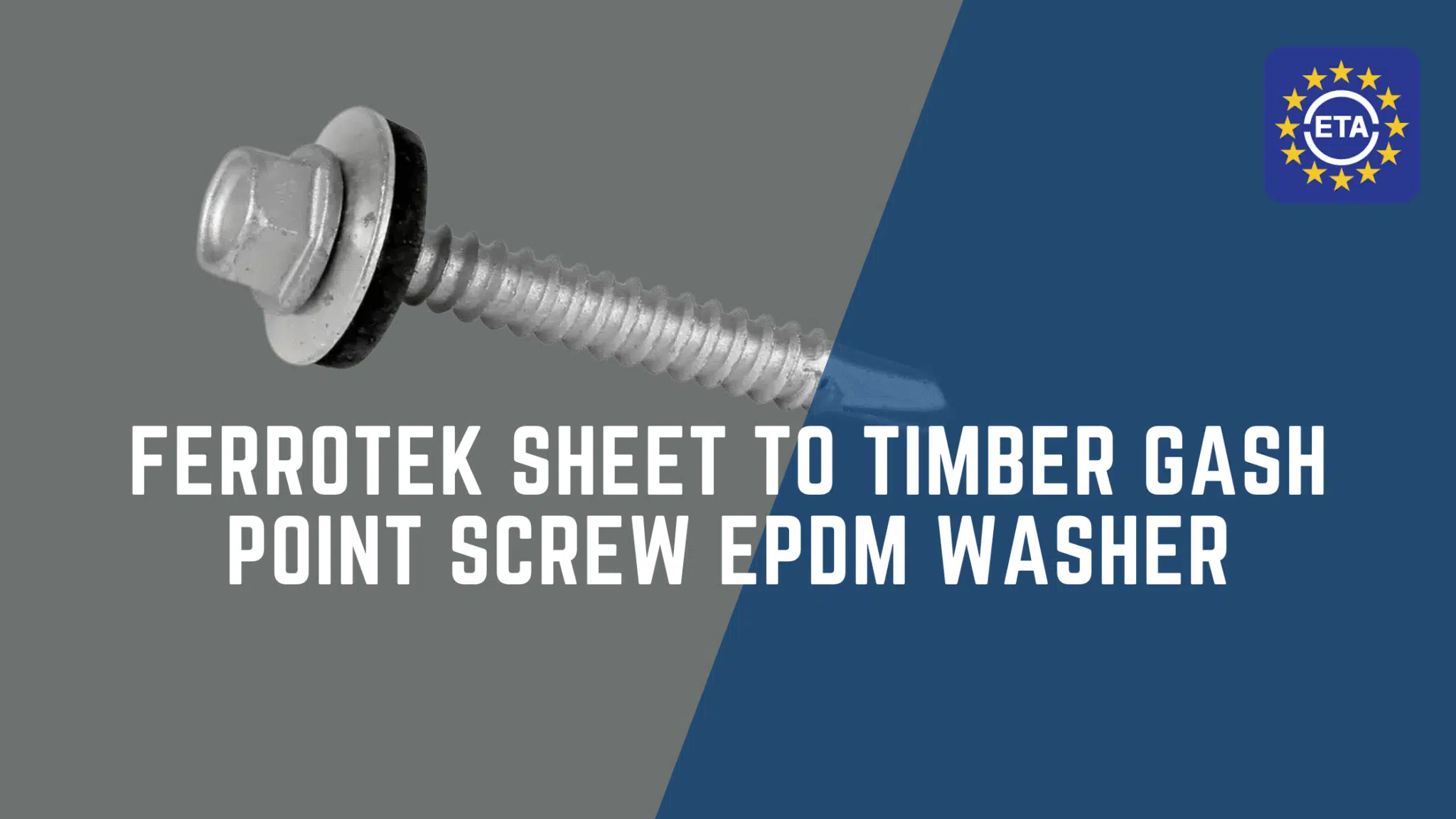

Over the course of your building or renovation projects, understanding the use of Ferrotek Sheet to Timber Gash Point Screw EPDM Washers can significantly enhance the durability and effectiveness of your installations. This guide provides you with important insights into the benefits and application of these washers, ensuring that your construction work is both safe and successful. By incorporating these into your projects, you will safeguard against leaks and prolong the lifespan of your structures, making your efforts more rewarding. When you fit ferrotek sheet to timber, these washers play a crucial role in creating a watertight seal that prevents moisture intrusion. Additionally, their robust design offers resistance against environmental factors, ensuring that your construction remains intact over time. Ultimately, utilizing these washers not only improves structural integrity but also reduces maintenance costs in the long run. Additionally, staying informed about the latest ferrotek sheet specifications for 2025 is crucial to ensure compliance with industry standards and to optimize performance. These specifications provide guidance on compatibility and installation practices that can further enhance the effectiveness of your construction efforts. Ultimately, adhering to these recommendations will help you achieve durable, leak-resistant installations that stand the test of time.

Key Takeaways:

- Designed specifically for use with Ferrotek sheet materials, ensuring optimal compatibility and performance when fastening to timber.

- The EPDM washer provides excellent weather resistance, helping to prevent moisture ingress and enhance the longevity of the installation.

- Features a gash point design that facilitates easier penetration into timber, promoting a secure and efficient fastening process.

The Unique Features of the Ferrotek Gash Point Screw

The Unique Features of the Ferrotek Gash Point Screw

The Ferrotek Gash Point Screw is engineered for exceptional performance, particularly in timber applications. Its gash point design provides a self-drilling capability, enabling you to easily penetrate materials without the need for pre-drilling. This innovation not only speeds up the installation process but also minimizes the risk of timber splitting. The combination of this innovative point design and high-strength steel construction ensures a robust fixing that stands up to various environmental stresses. The Ferrotek Gash Point Screw is also versatile, compatible with a range of materials beyond timber, including fiber cement, which adheres to industry-standard fibre cement screw specifications. Its ability to deliver reliable performance across different applications makes it an ideal choice for professionals seeking efficiency and durability. With this screw, users can expect consistent results, ensuring that projects are completed on time and with the utmost precision.

Design Innovations that Enhance Performance

Innovations in the design of the Ferrotek Gash Point Screw significantly improve its efficiency and reliability. The unique gash point creates a cleaner entry into the material, reducing friction and wear, which leads to prolonged screw life. Additionally, the optimal thread pitch facilitates better grip and holding power, making these screws particularly effective in soft and hardwood applications alike. Together, these features ensure you achieve secure and lasting results with less effort and time.

Materials Matter: The Role of EPDM Washers

The inclusion of EPDM washers in conjunction with Ferrotek Gash Point Screws plays a vital role in enhancing the overall performance of the assembly. EPDM, or ethylene propylene diene monomer, is known for its superior resistance to weathering, UV radiation, and extreme temperatures. This means that you can count on these washers to maintain an effective seal, ensuring that water and moisture do not compromise the integrity of your fixings.

The functionality of EPDM washers extends beyond basic sealing. Their flexibility allows them to conform to uneven surfaces, providing a reliable barrier that prevents leaks and potential damage. With a proven lifespan, these washers can withstand harsh environmental conditions without degrading, ensuring that your installations remain resilient. By integrating EPDM washers with Ferrotek Gash Point Screws, you enhance the durability of your structures, guaranteeing long-lasting performance in challenging conditions.

Installing the Ferrotek System: A Step-by-Step Approach

| Step | Description |

| 1 | Gather tools and materials required for installation. |

| 2 | Prepare the surface and layout, ensuring everything is level. |

| 3 | Align the Ferrotek Sheet to the timber surfaces. |

| 4 | Install screws, ensuring they pierce through the sheets appropriately. |

| 5 | Check for secure fittings and final adjustments if necessary. |

Preparation: Tools and Materials You’ll Need

Before starting the installation of the Ferrotek system, gather vital tools and materials, including a drill with the correct bit for your screws, a spirit level, a tape measure, and the Ferrotek sheets themselves. Also, have EPDM washers on hand to ensure a watertight fit. This preparation phase streamlines your installation process and enhances the overall reliability of the setup.

The Right Technique: Ensuring a Secure Fit

Achieving a secure fit during installation hinges on precise alignment and firm fastening techniques. Align the Ferrotek sheet accurately over the timber, making sure the pre-drilled holes match up. Use your drill to insert the screws, applying even pressure to avoid stripping. Position the EPDM washers beneath each screw head to create a tight seal, preventing moisture ingress. A snug fit is vital for the longevity of your installation, so double-check each screw’s tightness.

During the installation, be meticulous in applying consistent pressure while drilling, as this helps avoid issues such as misalignment or uneven fastening. If you find any resistance, reassess to ensure screws are penetrating the material at the right angles. Also, working in varying temperatures can affect material properties; hence, staying within recommended temperature ranges during installation can prevent long-term complications. Your attention to detail in this phase safeguards against future repair needs and ensures a durable outcome.

Common Challenges and How to Overcome Them

Common Challenges and How to Overcome Them

Throughout the installation and usage of Ferrotek Sheet to Timber Gash Point Screws, you may encounter several challenges. These often include issues with misalignment, which can undermine the integrity of your structure, and concerns relating to weather resistance and durability. Understanding these challenges and implementing effective solutions is vital for optimising the performance of the system and ensuring longevity.

Misalignment and Its Impact on Integrity

Misalignment during installation can lead to poor load distribution and compromised structural integrity. This issue can result from improper drilling angles or inadequate pre-drilling, affecting the screw’s grip on the timber. To avoid these problems, ensure that you use appropriate guides to maintain correct angles, and regularly check the alignment of your materials as you proceed.

Addressing Weather Resistance and Durability Issues

Ensuring weather resistance and durability becomes vital when utilising the Ferrotek system, especially in varying climates. Exposure to moisture may result in corrosion and reduced lifespan of the screws. To combat this, consider employing high-grade EPDM washers that enhance sealing properties and provide an added layer of protection against the elements. Regular inspections and maintenance are also advised to detect any signs of wear early, helping you prolong the system’s performance and ensure its reliability.

Utilising EPDM washers not only enhances the weather resistance of your installation but also contributes to overall durability. These washers are known for their excellent resistance to UV rays, ozone, and extreme temperatures, which makes them particularly suitable for outdoor applications. Regularly checking these seals during routine maintenance can prevent moisture ingress, thereby safeguarding the integrity of your installation for years to come. Furthermore, opting for screws that have a protective coating can provide additional resistance against environmental factors, ensuring that your structure remains robust and stable over time.

Maintenance Tips for Longevity and Performance

Regular maintenance of your Ferrotek sheet and EPDM washer system not only ensures peak performance but also extends its lifespan. To maintain longevity, perform the following:

- Inspect for any signs of wear or damage on the washers and screws.

- Ensure proper sealing to prevent moisture intrusion which can lead to corrosion.

- Clean the installation site periodically to avoid build-up of debris.

- Replace worn components immediately to prevent further issues.

Thou shall keep these checks regular for optimal performance.

Routine Checks to Prevent Common Problems

Routine inspections are fundamental in identifying common problems early. Check for signs of corrosion or rust on the screws and washers, as any deterioration can compromise the structural integrity of your installation. Additionally, monitor for any looseness in the fasteners, which may indicate that the system requires tightening. Regular maintenance guarantees that you can address minor issues before they escalate into significant complications.

Understanding the Lifecycle of EPDM Washers

The lifecycle of EPDM washers typically spans several years, largely dependant on environmental factors and usage conditions. These washers are designed to withstand a range of temperatures and offer excellent resistance to ozone and UV radiation. In ideal conditions, the performance can remain consistent for up to a decade. However, exposure to extreme climates or aggressive chemicals can significantly shorten their life.

When evaluating the lifecycle of EPDM washers, consider that factors such as UV exposure, temperature fluctuations, and physical abrasion impact their integrity. Regular monitoring is vital; inspections should address any cracks, hardness changes, or loss of elasticity, which are indicators of material degradation. Understanding these aspects enables you to replace washers as needed, ensuring ongoing effectiveness in your Ferrotek system. Optimising their performance can ultimately reduce maintenance costs and enhance system reliability.

Real-Life Applications: Where to Use Ferrotek Products

Ferrotek products find their strength in a multitude of environments, offering versatile solutions for both residential and commercial settings. From roofing and cladding systems in high-rise buildings to residential decking and garden installations, their exceptional durability and performance shine through. Whether you’re launching on a DIY home project or managing a large-scale construction site, Ferrotek products provide reliable options for any application where quality and longevity are paramount.

Residential vs Commercial Applications

In residential settings, Ferrotek products serve well for roofing, fencing, and outdoor structures, ensuring your home withstands the elements. For commercial applications, these products excel in high-traffic areas, providing robust solutions for industrial cladding and façade systems. The adaptability of Ferrotek ensures it meets the varying demands across these different environments while maintaining high standards of quality and performance.

Innovations in Sustainability and Efficiency

Innovations in Sustainability and Efficiency

Ferrotek is at the forefront of sustainability, offering products that aim to reduce environmental impact. Their sheets and washers are designed to maximise energy efficiency in building projects, contributing to lower operational costs and a smaller carbon footprint. By integrating eco-friendly materials and advanced manufacturing processes, Ferrotek products not only provide durability but also support green building initiatives within both residential and commercial sectors.

Recent advancements in Ferrotek’s product lines involve the incorporation of recycled materials into their manufacturing process, enhancing sustainability without compromising on performance. Through research and development, they have also improved the thermal insulation properties of their products, which can significantly reduce energy consumption and promote a more sustainable lifestyle. Moreover, partnerships with green certification bodies showcase Ferrotek’s commitment to meeting stringent environmental standards, reflecting the growing trend towards eco-conscious building practices.

Conclusion

The Guide to Ferrotek Sheet to Timber Gash Point Screw EPDM Washer provides you with imperative information to ensure optimal performance in your projects. By understanding the benefits and correct application of these components, you can enhance your construction efficiency and durability. Implementing the right techniques will enable you to achieve reliable results while safeguarding the integrity of your structures. Rely on this guide to make informed decisions for your next installation, ensuring you maximise both reliability and longevity in your builds. By integrating the ferrotek sheet advantages for screws into your workflow, you will notice a marked improvement in fastener performance and resistance to environmental factors. Additionally, these components help reduce wear and tear, ultimately extending the life of your installations. Emphasizing the proper use of these materials will significantly benefit your overall construction practices.

Ferrotek Sheet to Timber Gash Point Screw EPDM Washer FAQ

Q: What is the purpose of using a Ferrotek Sheet to Timber Gash Point Screw with an EPDM washer?

A: The Ferrotek Sheet to Timber Gash Point Screw is specifically designed for securing Ferrotek sheets to timber substrates. The gash point helps to penetrate the surface easily, while the EPDM washer provides a weatherproof seal, preventing moisture ingress and protecting the integrity of both the sheet and timber. This innovative fastening solution not only ensures a strong grip but also allows for quick and efficient installation, making it ideal for various construction applications. The ferrotek sheet gash point screw is compatible with a range of timber types, providing versatility in project execution. Additionally, its robust design enhances durability, ensuring long-lasting performance even in challenging weather conditions.

Q: How do I determine the correct size of screws and washers needed for my project?

A: The size of screws and washers needed depends on the thickness of the Ferrotek sheets and the timber they are being attached to. It is recommended to consult the product specifications or guidelines provided by the manufacturer. Generally, ensuring that the screw length is slightly longer than the combined thickness of the sheet and timber is vital for effective attachment.

Q: Can I use Ferrotek screws and EPDM washers for outdoor applications?

A: Yes, Ferrotek Sheet to Timber Gash Point Screws with EPDM washers are designed for outdoor use. The EPDM washers provide excellent resistance to water, UV rays, and varying temperatures, making them suitable for external applications such as roofing, cladding, and other exposed areas.

Q: How should I install the Ferrotek screws to achieve the best results?

A: To install the Ferrotek screws effectively, first, position the Ferrotek sheet over the timber substrate, ensuring proper alignment. Pre-drilling may be necessary for hardwoods to avoid splitting. Insert the screw through the EPDM washer, then drive the screw into the timber until it is snug, but be careful not to overtighten as this might damage the sheet or washer. For optimal results, use a torque setting on your drill to prevent excessive force during installation. Additionally, ensure that there are no debris or obstructions between the Ferrotek sheet and the timber substrate. For further guidance, consider consulting the ferrotek sheet screw installation tips provided by the manufacturer.

Q: Are there any specific maintenance requirements for installations using Ferrotek screws and washers?

A: Maintenance for installations using Ferrotek screws and EPDM washers is minimal. However, it is advisable to periodically inspect the screws and washers for signs of wear or corrosion, especially in harsh weather conditions. If any damage is noted, replacing the affected screws and washers promptly can help maintain the integrity and weather-resistance of the installation.

The Unique Features of the Ferrotek Gash Point Screw

The Unique Features of the Ferrotek Gash Point Screw Common Challenges and How to Overcome Them

Common Challenges and How to Overcome Them Innovations in Sustainability and Efficiency

Innovations in Sustainability and Efficiency