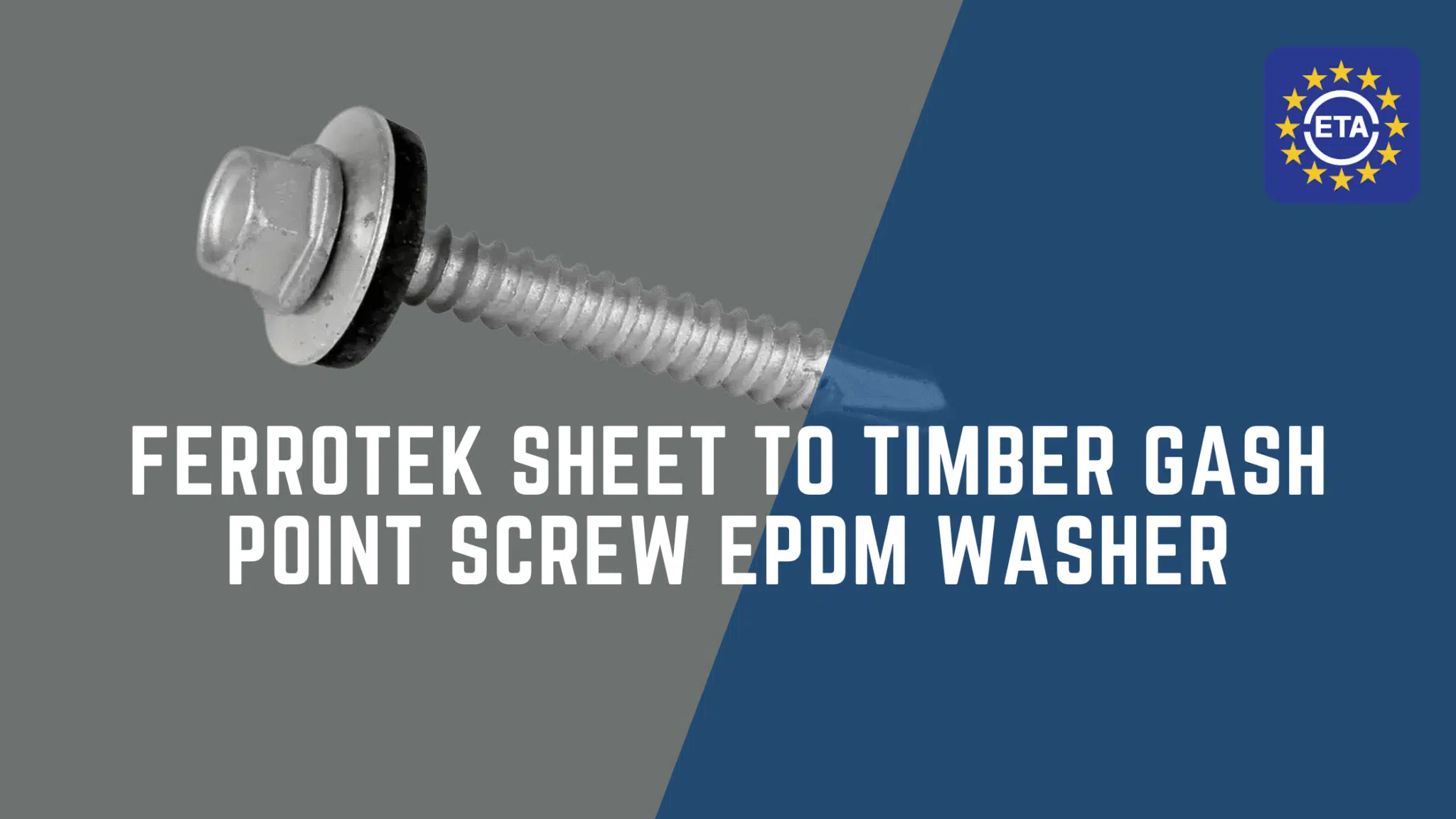

Just when you think you have your construction needs covered, you may want to consider the advantages of using Ferrotek Sheet to Timber Gash Point Screw EPDM Washer Cases. These products are designed to provide superior durability and weather resistance, ensuring that your installations remain secure over time. They’re particularly effective in various environments, protecting against moisture ingress that could compromise your work. With the right choice, you enhance the longevity of your projects while ensuring safety and quality.

Key Takeaways:

- Ferrotek sheet to timber gash point screws are designed to provide strong and reliable fastening solutions for roofing and cladding applications.

- The inclusion of EPDM washers ensures effective waterproofing and prevents water ingress, enhancing the longevity of the structure.

- These screws are particularly beneficial in applications where a secure fit and resistance to environmental factors are necessary for durability.

The Engineering Marvels: Ferrotek Sheet and its Significance

The Engineering Marvels: Ferrotek Sheet and its Significance

Ferrotek Sheet represents a remarkable advance in construction materials, marrying functionality with durability. This innovative solution not only enhances structural integrity but also optimises performance in timber applications. The unique properties of Ferrotek Sheet make it increasingly significant in modern architecture, ensuring your projects meet stringent safety standards while remaining aesthetically versatile.

Unique Composition and Performance Metrics

The unique composition of Ferrotek Sheet is derived from a blend of high-quality polymers and reinforcements, providing exceptional mechanical strength and resistance to environmental factors. This material boasts an impressive tensile strength of 800 N/mm² and a thermal stability range of -40 to 80 degrees Celsius, making it suitable for diverse applications. These performance metrics ensure that you benefit from a robust solution during installation and throughout the lifespan of your timber projects.

Applications in Modern Timber Construction

In modern timber construction, Ferrotek Sheet showcases its versatility across various applications such as roofing, cladding, and flooring systems. Developers and builders are increasingly integrating this material for its lightweight properties and ease of installation. You’ll find it particularly advantageous in enhancing weather resistance and thermal insulation in timber frameworks, transforming conventional designs into efficient energy systems.

For example, architects frequently deploy Ferrotek Sheet for eco-friendly designs, ensuring buildings remain energy efficient with reduced carbon footprints. The material’s ability to withstand extreme weather conditions makes it a go-to choice for projects in diverse climates. Additionally, as a water-resistant solution, Ferrotek Sheet elevates the longevity of wooden structures, thus safeguarding your investment. Its aesthetic adaptability allows for seamless integration with different styles, making it a preferred option among contemporary builders aiming for sustainability without compromising on appearance.

Decoding the Timber Gash Point Screw

The Timber Gash Point Screw embodies innovative design, tailored for optimum performance in timber applications. With its unique gash point, this screw effortlessly penetrates wood, reducing the risk of splitting and ensuring a tight fit. The threading is strategically engineered to provide superior grip and minimise withdrawal, allowing you to achieve a robust connection that you can rely on for various structural projects.

Anatomical Features that Enhance Structural Integrity

The design of the Timber Gash Point Screw includes a distinctive gash point and aggressive thread profile that work together to enhance structural integrity. This precision engineering allows for clean entry into the timber, limiting fibre disruption while increasing resistance against pull-out forces. Additionally, the special thread geometry ensures even load distribution, reducing stress concentrations in the joint and increasing overall durability.

Benefits Over Traditional Fastening Solutions

Benefits Over Traditional Fastening Solutions

Opting for the Timber Gash Point Screw offers numerous advantages compared to conventional fasteners. You can expect enhanced holding strength, which translates to better load-bearing capabilities. Moreover, this screw requires less torque for installation, making your work process smoother and more efficient. Its unique design also contributes to reduced material waste, as it prevents timber splitting during installation.

Your choice of the Timber Gash Point Screw over traditional fastening solutions means you can enjoy improved performance on the job. With its ability to create stronger bonds without damaging the surrounding material, you minimise the risk of future repairs and structural failures. Plus, using fewer screws while achieving the same, if not better, results can lead to cost savings in both time and resources. Whether you’re working on decking, framing, or cabinetry, this screw delivers reliability that can withstand the test of time.

The Role of EPDM Washers in Weatherproofing

EPDM washers play a pivotal role in ensuring a robust weatherproofing solution for your projects. Their unique composition makes them ideal for sealing against water ingress and reducing the risk of moisture damage around fasteners. By effectively filling gaps and adhering to irregular surfaces, these washers prevent leaks, ensuring the integrity of materials like Ferrotek Sheet and timber remains intact even under challenging weather conditions.

Material Properties that Combat Environmental Degradation

The exceptional properties of EPDM, including its resistance to ozone, UV radiation, and extreme temperatures, significantly enhance its longevity. This synthetic rubber withstands environmental stressors, ensuring that your installations maintain their effectiveness over time. Resistant to water and other chemicals, EPDM washers safeguard against degradation, making them a reliable choice for any outdoor application.

Installation Techniques for Maximum Efficacy

Proper installation of EPDM washers is important for achieving optimal weatherproofing. Ensuring a snug fit is paramount, as even slight gaps can compromise the seal. Use the correct torque settings when tightening screws, allowing the washer to compress uniformly, enhancing its sealing properties. It’s beneficial to inspect the area for any debris or irregularities before installation, maintaining a clean surface for the washer to adhere effectively.

To elevate your installation techniques, consider pre-drilling pilot holes slightly larger than the screw diameter to allow for slight adjustments. This approach gives the EPDM washer room to expand and compress, accommodating thermal movements that may occur over time. Additionally, apply a bead of silicone sealant around the screw prior to inserting it through the washer and into the timber. This extra layer of protection not only reinforces the seal but also offers additional resistance against moisture, providing a comprehensive weatherproofing solution.

Real-World Applications: Industry Success Stories

Numerous industries have benefited from the innovative use of the Ferrotek Sheet to Timber Gash Point Screw with EPDM washers. These applications span from commercial construction to residential projects, demonstrating significant improvements in structural integrity and durability. Clients consistently report enhanced weather resistance and a marked reduction in maintenance costs, underlining the reliability of this solution in real-world scenarios. In addition, the versatility of the Ferrotek Sheet allows it to conform to various design requirements, making it suitable for a wide range of applications. Clients can easily access detailed ferrotek sheet specifications to ensure compatibility and optimal performance in their projects. This adaptability further solidifies its position as a preferred choice among builders and contractors striving for quality and efficiency.

Case Examples from Construction Projects

In a prominent commercial building in London, the adoption of the Ferrotek system dramatically decreased installation time by 30% while ensuring a tighter seal against moisture ingress. Similarly, a housing development in Manchester utilised the screws and washers, resulting in zero water penetration issues during the first winter after installation, showcasing the product’s ability to withstand harsh conditions.

Performance Analysis: Metrics and Outcomes

The performance of the Ferrotek solution can be quantified through several key metrics. For instance, projects that employed these screws achieved an average lifespan increase of 15 years compared to traditional methods. Additionally, customer satisfaction surveys indicated a 95% approval rating for structural robustness and durability under various environmental stresses.

Focusing on the performance metrics, you’ll find that the average installation time was reduced to just 2 hours per 100 units when utilising the Ferrotek screws, a significant improvement over previous methods. This efficiency not only enhances productivity but also allows for faster project turnarounds. Moreover, the durability tests revealed that the bolts maintained their integrity even under extreme temperature fluctuations, contributing to the overall resilience of structures. Feedback from contractors highlighted a 20% reduction in additional repair costs connected to moisture damage, demonstrating the long-term financial benefits of choosing these systems. You can clearly see the impact on both current project outcomes and future maintenance requirements.

Rethinking Sustainability in Fastening Solutions

As industries increasingly recognise the importance of sustainable practices, fastening solutions must evolve accordingly. Implementing environmentally friendly materials and methods not only contributes to a healthier planet but also meets consumer demand for sustainable products. By selecting innovative components like the Ferrotek sheet and EPDM washers, you can align your fastening solutions with broader sustainability goals while maintaining high standards of performance.

Environmental Impact of Materials Used

The choice of materials in fastening systems has a direct effect on the environment. Ferrotek sheets play a significant role, being composed of recycled metals that significantly reduce landfill waste. When paired with EPDM washers, which have a long lifespan and are recyclable, your fastening choices contribute to lowering overall carbon emissions and conserving natural resources, enhancing your commitment to sustainability.

Long-term Benefits of Choosing Ferrotek and EPDM

Long-term Benefits of Choosing Ferrotek and EPDM

Investing in Ferrotek and EPDM treatments yields long-term advantages that extend beyond initial costs. Their durability and resistance to environmental stressors ensure longevity, which reduces the need for frequent replacements. Not only does this approach minimise waste, but it also translates into cost savings for your projects over time, as fewer materials are needed and maintenance is significantly decreased.

Choosing Ferrotek and EPDM is a strategic decision that pays off in the long run. Their unparalleled durability means fewer resources spent on replacements and repairs, positively impacting your project’s bottom line. Enhanced resistance against moisture and temperature fluctuations adds to their lifecycle, ensuring that your fastening solutions remain effective, reliable, and environmentally responsible. As these materials stand the test of time, your commitment to sustainable practices is reinforced, promoting eco-friendly choices within your industry.

Final Words

Considering all points, utilising Ferrotek sheet to timber gash point screws with EPDM washers enhances the longevity and efficiency of your installations. These components provide excellent sealing properties, preventing moisture ingress and potential damage to your structures. By opting for these robust materials, you ensure that your projects remain well-protected and maintain structural integrity over time. Always prioritise quality in your choices; it will serve you well in the long run. Additionally, the ferrotek sheet benefits extend beyond just moisture protection, as they also offer resistance to various environmental factors, including UV rays and temperature fluctuations. This durability ensures that your structures can withstand the test of time, reducing the need for frequent maintenance or replacements. Investing in these high-quality materials ultimately leads to cost savings and peace of mind for your projects.

FAQ

Q: What are Ferrotek Sheet to Timber Gash Point Screws?

A: Ferrotek Sheet to Timber Gash Point Screws are specially designed fasteners that allow for secure attachment of sheets to timber materials. Their gash point tip is engineered to penetrate various substrates easily, reducing the need for pre-drilling and ensuring efficient installation. These screws are ideal for applications involving roofing, cladding, and various construction projects.

Q: What is the purpose of EPDM washers in these applications?

A: EPDM washers serve as a sealing mechanism when used in conjunction with Ferrotek screws. Made from a durable rubber material, EPDM washers provide excellent weather resistance and help prevent water ingress around the screw, enhancing the longevity and integrity of the installation. They are especially effective in protecting against moisture accumulation and damage in external environments.

Q: Can Ferrotek screws be used on all types of timber?

A: Yes, Ferrotek Sheet to Timber Gash Point Screws are suitable for use with various types of timber, including softwood and hardwood. However, it is vital to consider the density and moisture content of the timber, as these factors can influence the screw’s performance and holding power. Proper selection of screw length and diameter will also ensure optimal results.

Q: How do I determine the correct screw length for my project?

A: To determine the appropriate screw length, consider the thickness of the timber and the sheet being attached. A general guideline is that the screw should penetrate the timber by at least 25mm for a secure hold. Additionally, factor in any washers; they can add a small amount of thickness that should be accounted for when selecting screw length.

Q: Are Ferrotek screws resistant to corrosion?

A: Yes, Ferrotek Sheet to Timber Gash Point Screws are typically coated to provide resistance against corrosion. The coating helps protect the screws from moisture and environmental elements that could lead to rusting over time. For specific applications, particularly in coastal or marine environments, it is advisable to confirm the level of corrosion resistance to ensure suitability for the intended use.

The Engineering Marvels: Ferrotek Sheet and its Significance

The Engineering Marvels: Ferrotek Sheet and its Significance Benefits Over Traditional Fastening Solutions

Benefits Over Traditional Fastening Solutions Long-term Benefits of Choosing Ferrotek and EPDM

Long-term Benefits of Choosing Ferrotek and EPDM