Many of you may be unaware of the significant advancements in concrete masonry screws, which have evolved to meet the demands of modern construction. These innovative fasteners offer enhanced performance, greater durability, and a simplified installation process compared to traditional methods. In this blog post, we will explore the latest developments in concrete masonry screws, helping you understand how these advancements can improve your projects and ensure safety in your building practices.

Key Takeaways:

- Innovative Design: Recent advancements in the design of concrete masonry screws enhance performance and ease of installation.

- Material Development: New materials used in the manufacturing process improve durability and resistance to environmental factors.

- Thread Technology: Enhanced thread patterns provide superior grip and reduced installation torque, making them more efficient.

- Versatility: The latest screws are designed for a wider range of applications, accommodating various masonry types.

- Environmental Impact: Sustainability initiatives in production methods contribute to a reduced carbon footprint in the manufacturing of these screws.

The History of Concrete Masonry Screws

The evolution of concrete masonry screws can be tracked back can be traced back to the early 20th century when the need for efficient fastening solutions in masonry work became apparent. Initially, traditional anchors and bolts were utilised, but as construction demands increased, innovative fastening techniques emerged, leading to the development of concrete masonry screws designed specifically for optimal adhesion and structural integrity.

Early Innovations

An array of early innovations in fastening technology laid the groundwork for concrete masonry screws. Pioneering engineers experimented with various materials and designs to enhance grip and stability, ultimately leading to the creation of screws that could penetrate concrete efficiently, drastically improving installation speed and reliability.

The Impact of Material Science

Below the surface, advancements in material science have profoundly impacted the performance of concrete masonry screws. New composites and alloys allow for improved strength and durability, enabling screws to withstand increased loads and environmental conditions without compromising integrity.

It is important to recognise that the enhancement in material science has led to the development of screws that are both lighter and stronger, making installation safer for you. These innovations have allowed screws to maintain their structural integrity even in demanding environments, thus reducing the risk of failure under pressure. With a better understanding of how materials interact with concrete, you can choose screws that not only meet but exceed modern building standards.

Current Technologies in Concrete Masonry Screws

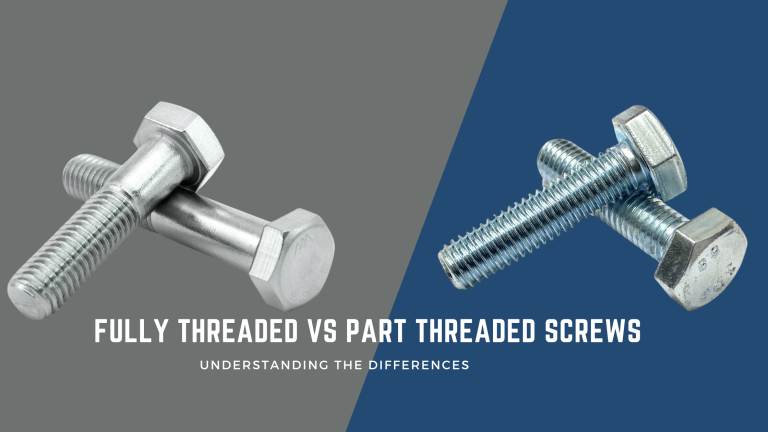

Screw Design and Functionality

Advances in Coating and Corrosion Resistance

Against the backdrop of environmental challenges, advances in coating and corrosion resistance have become paramount. Modern coatings protect your screws from harsh conditions, prolonging their lifespan and maintaining structural integrity.

Advances in coating technologies now offer you enhanced protection against corrosion, which is vital in ensuring the durability of your concrete masonry screws. Cutting-edge coatings, such as zinc-based and polymer formulations, form a robust barrier that safeguards your screws from corrosive elements. These innovations not only enhance the lifespan of your fasteners but also minimise maintenance costs, making them a cost-effective choice. Embracing these advancements means you’re investing in sustainable solutions that stand the test of time.

Applications of Concrete Masonry Screws

Your understanding of concrete masonry screws is vital for their effective application in various settings. These versatile fasteners are designed to provide reliable and robust anchoring solutions in both residential and industrial environments, ensuring safety and durability in all constructions.

Residential Construction

Before launching on your home improvement projects, consider how concrete masonry screws can simplify your tasks. They are perfect for securing elements such as decking, fences, and even heavy fixtures to concrete, providing a sturdy hold that enhances the durability of your residential structures. Additionally, understanding how to install concrete screws can greatly reduce the time and effort required for your projects. Proper installation ensures that your fixtures remain secure for years to come, resisting the wear and tear of the elements. With the right tools and knowledge, you can achieve professional-quality results right at home.

Commercial and Industrial Uses

Industrial settings often require exceptional strength and reliability, and concrete masonry screws deliver just that. These fasteners are tailored for use in various applications, including securing machinery, fitting fixtures, and installing safety barriers, providing a swift, easy-to-install solution that saves time and effort.

Another point to note about commercial and industrial uses of concrete masonry screws is their strong resistance to environmental factors, making them suitable for outdoor installations. The design of these screws allows for quick installation and removal, which can be a significant advantage during maintenance or modifications. It is vital to choose the right size and type, as failure to use the correct specifications could lead to safety hazards, underscoring the importance of ensuring the right fit for your specific needs.

Performance Comparisons

To determine the best option for your project, it’s important to analyse the differences in performance between traditional fasteners and modern concrete masonry screws. Consider the following comparison:

| Aspect | Concrete Masonry Screws |

|---|---|

| Ease of Installation | Simple and quick; no pre-drilling required |

| Material Compatibility | Specifically designed for concrete and masonry |

| Risk of Damage | Lower risk of cracking or damaging the substrate |

Traditional Fasteners vs Concrete Masonry Screws

Load-Bearing Capacity and Durability

Fasteners used for concrete must offer reliable load-bearing capacity and durability to ensure structural integrity. It’s important that you consider the specific requirements of your project before choosing your fastener type.

Comparisons highlight that concrete masonry screws typically exhibit superior load-bearing capacity compared to traditional fasteners. Their unique threads provide a strong grip within the concrete, enhancing durability. Furthermore, these screws are less susceptible to corrosion, ensuring long-term performance in various environments. With higher shear strength, you can confidently use concrete masonry screws in heavy-load applications, affirming your choice for robust construction solutions.

Installation Techniques and Best Practices

Not only should you ensure that your surface is prepped correctly before installation, but it’s also vital to use the correct techniques to secure your masonry screws effectively. Always drill pilot holes to avoid splitting your materials and ensure a snug fit. Using a torque wrench can help you achieve the optimal tightness without over-tightening, which may damage your assembly or the masonry structure.

Tools and Equipment Needed

Along with your concrete masonry screws, you’ll need a variety of tools for a successful installation. Essential equipment includes a hammer drill, a set of drill bits, a torque wrench, and a suitable screwdriver. A level and safety goggles are also recommended to guarantee precision and protect yourself during the process.

Tips for Optimal Performance

Best practices for optimal performance include ensuring that your drill bits are sharp and suited for masonry. Use a hammer drill with a compatible concrete masonry screw size, and be mindful of your drilling angle. Make sure to choose the right screw length and gauge for the materials you are working on.

- Ensure drill bits are sharp

- Maintain a proper drilling angle

- Choose the right screw length and gauge

Assume that following these guidelines will lead to a solid installation, enhancing the durability of your project.

Plus, it’s beneficial to include a few additional details for optimal performance. Ensure your materials are dry before installation, as moisture can weaken hold strength. Additionally, check if the base material is adequately cured, as this plays a significant role in the performance of your masonry screws.

- Check for proper material curing

- Install in dry conditions

- Confirm that materials are level

Assume that by adhering to these best practices, your installations will be both secure and long-lasting.

Future Trends in Concrete Masonry Screws

Sustainability and Eco-Friendly Designs

Masonry construction is increasingly adopting eco-friendly practices, including the development of sustainability-focused concrete masonry screws. Manufacturers are aiming to produce screws from recycled materials or using energy-efficient manufacturing processes, allowing you to contribute to environmental conservation without sacrificing performance.

Innovations on the Horizon

Sustainability in concrete masonry screws is leading to innovative changes that enhance functionality while reducing environmental impact. Smart technologies may soon be integrated into screws, offering real-time analytics on load performance and health monitoring of structures. Furthermore, the exploration into biodegradable materials could revolutionise how screws interact with masonry environments, minimising long-term waste and enhancing durability. These advancements not only serve to improve efficiency but also support eco-conscious building practices, allowing you to align your projects with modern sustainability goals.

Summing up

Conclusively, the evolution of concrete masonry screws has introduced significant advancements that enhance your construction projects. You can benefit from the improved designs and materials that offer better durability and strength, making your installations more reliable. As you explore the latest options available in the market, you will find innovations tailored to improve efficiency and ease of use, ensuring that you achieve optimal results in your masonry work.

Concrete Masonry Screws FAQ

Q: What advancements have been made in the design of concrete masonry screws?

A: Recent developments in the design of concrete masonry screws include enhanced thread geometry that allows for better grip and reduced installation torque. The materials used have also evolved, with many screws now being produced from high-strength, corrosion-resistant alloys, making them suitable for various environments. Additionally, some concrete masonry screws feature self-tapping tips that eliminate the need for pre-drilling, thereby streamlining the installation process significantly.

Q: How do modern concrete masonry screws compare to traditional fastening methods?

A: Modern concrete masonry screws offer several advantages over traditional fastening methods, such as expansion anchors or plugs. These screws provide a more reliable hold in concrete and masonry due to their unique threading, which digs into the material instead of relying on expansion. This leads to improved holding power and stability, especially in applications subjected to vibration or dynamic loads. Moreover, the ease of installation and removal of concrete masonry screws makes them a more practical choice for both professionals and DIY enthusiasts.

Q: Are there specific applications where the latest concrete masonry screws should be used?

A: The latest concrete masonry screws are ideal for a wide range of applications, including mounting fixtures, securing shelving, attaching railings, and undertaking concrete repairs. They are particularly beneficial in outdoor construction projects, where their corrosion-resistant properties offer longevity in harsh weather conditions. Additionally, their ability to be used in various densities of concrete and masonry makes them versatile for both light and heavy-duty applications.