Many builders and tradespeople understand that using Fibre Cement to Timber Steel Screws is crucial for ensuring the longevity and integrity of your projects. These screws are specifically designed to provide exceptional durability and reliability in constructing buildings, suitable for various applications, including bricklaying, carpentry, and roofing. With their robust construction and effective gash point technology, they penetrate materials effortlessly, preventing splitting and ensuring a firm hold. This makes your work more efficient and enhances the overall quality of your craft, with fewer callbacks and repairs. Incorporating these screws into your toolkit not only meets the demands of different trades but also showcases your commitment to quality and durability.

Key Takeaways:

- Unmatched Durability: Fibre cement to timber screws are engineered to withstand the rigours of various trades, making them an important choice for builders and tradespeople seeking long-lasting performance. Their robust construction ensures reliable fastening even under demanding conditions, reducing the need for frequent maintenance and replacements.

- Optimised Design for Easy Installation: These screws feature a reliable gash point that allows for quick and easy penetration into timber. This design not only speeds up the installation process for carpenters and flooring contractors but also minimises the risk of splitting the timber, ensuring a clean and professional finish.

- Versatile Applications: Ideal for multiple applications in construction, these screws excel in securing fibre cement sheeting to timber frameworks. This versatility makes them a go-to choice for builders and joiners working on both residential and commercial projects, ensuring a solid connection that enhances overall structural integrity.

- Corrosion Resistance: Designed with weather and moisture exposure in mind, these screws boast excellent corrosion resistance. This feature is particularly beneficial for roofers and outdoor construction workers, as it guarantees long-term performance even in challenging weather conditions, thus safeguarding the integrity of their work.

- Enhanced Load-Bearing Capacity: Fibre cement to timber screws provide superior load-bearing capabilities, making them perfect for applications requiring strong holding power, such as when installing flooring or structural components. This characteristic is vital for various tradespeople, ensuring safety and reliability in every build.

Understanding Fibre Cement to Timber Applications

Before selecting the right fasteners, you should comprehend the unique characteristics of fibre cement and timber applications. These materials, often used in roofing and wall cladding, require specialised steel screws designed to create a robust bond while accommodating the properties of both components. The right screws not only enhance structural integrity but also facilitate long-lasting connections that withstand various environmental challenges.

Mechanical Properties and Load Requirements

Mechanical Properties and Load Requirements

Around your construction site, it’s vital to assess the mechanical properties and load requirements of your chosen fasteners. The fibre cement to timber screws are designed with exceptional tensile strength, ensuring they can support heavy loads without deformation. Their gash point design allows for efficient penetration, minimising the risk of splitting and maximising the screws’ holding power in both timber and fibre cement applications.

Environmental Exposure Considerations

Timber and fibre cement are often exposed to varying weather conditions, making it vital to use durable fasteners. Choosing the right screws also means considering factors like moisture, UV radiation, and temperature fluctuations. Using fibre cement to timber screws provides a robust solution to these challenges, offering resistance against corrosion and degradation, ensuring longevity and reliability in your constructions.

Considering the environmental conditions to which your projects are subjected, it’s vital to use the most resilient materials on the market. Your fibre cement to timber screws are specifically engineered to withstand extreme moisture levels, UV exposure, and temperature changes. This makes them an ideal choice for outdoor constructions where traditional screws might fail. The anti-corrosion properties of these screws ensure that you won’t face frequent replacements, thereby reducing long-term maintenance costs while enhancing the durability of your work—giving you peace of mind in every project.

Key Features of Steel Screws

Now, let’s probe into the key features that make steel screws important for construction. These fasteners are designed to meet the demanding needs of various trades, ensuring durability and reliability:

- Superior Strength for enhanced load-bearing capacity

- Precision Gash Point for easy penetration into materials

- Corrosion Resistance to withstand harsh environmental conditions

- Varied Lengths to accommodate different applications

- Versatile Applications suitable for timber and fibre cement

Knowing these features will help you choose the right screws for your projects, ensuring a robust and lasting construction.

Corrosion Resistance and Coating Types

Between various materials used in construction, corrosion resistance is paramount for the longevity of your projects. Steel screws come with various coatings designed to combat rust and degradation:

| Coating Type | Benefits |

| Zinc Plating | Offers basic corrosion protection |

| Galvanised | Provides a stronger barrier against rust |

| Epoxy Coated | Highly resistant to chemicals and moisture |

| Stainless Steel | Best for high-corrosion environments |

The right coating can significantly enhance the lifespan of your screws, making them a practical choice for a variety of trades.

Thread Design and Holding Power

Thread Design and Holding Power

Types of thread design play a critical role in the performance of steel screws. The innovative thread geometry maximises holding power and reduces the risk of loosening over time. For instance, self-tapping designs allow for easy installation in fibre cement, while deep threads provide superior grip in timber applications.

In addition, many builders appreciate that specific thread features, such as fine pitch threads, enhance the connection strength between materials, especially when working with varied densities of timber or cement boards. This design consideration is especially beneficial when tradespeople, like carpenters and electricians, require reliable performance in their applications. The effective combination of thread design and material durability ensures that your projects not only meet construction standards but also stand the test of time, providing lasting support and security in every build.

Installation Best Practices

Unlike standard fasteners, installing Fibre Cement to Timber Screws requires a few specific techniques that ensure their durability and effectiveness. For optimal performance, always check the manufacturer’s guidelines, as following these best practices not only improves your build quality but also significantly reduces the risk of future structural issues.

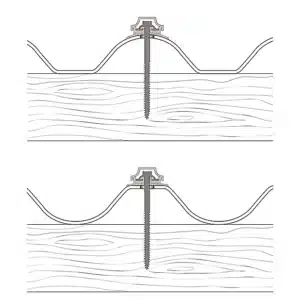

Pre-drilling Requirements

The use of pre-drilling is highly recommended when working with fibre cement materials. This technique helps to prevent cracking and ensures a secure fit, allowing your screws to anchor effectively in timber. A correctly sized drill bit will make all the difference in achieving a robust installation.

Proper Spacing and Edge Distance

Among the vital aspects of screw installation is the proper spacing and edge distance. This ensures that your screws hold securely without compromising the integrity of the materials involved. Maintaining an adequate distance can prevent material failure and enhance the overall stability of your construction.

Requirements for proper spacing dictate that screws should be placed at least twice the diameter of the screw from the edge of the timber and spaced appropriately to avoid concentrated stress points. This is particularly important when working with fibre cement, as insufficient spacing can lead to significant weakening of the structure. Ensure you adhere to these guidelines to maintain the safety and longevity of your build. In addition to preventing structural compromise, proper spacing also allows for expansion and contraction of materials, vital in varying weather conditions.

When you choose our Fibre Cement to Timber Screws for your projects, you’re investing in durable solutions tailored for tradespeople like builders and carpenters. These long-lasting screws feature a reliable gash point, designed specifically for seamless penetration into harsh materials, thus providing excellent holding power, necessary for high-stress applications. Whether you’re tackling roofing work, flooring installations, or heavy-duty construction, the features of our screws facilitate easy handling and installation. Builders will appreciate the significant reduction in time and effort required while ensuring your projects remain safe and structurally sound. This versatility benefits not only construction but various trades where strong, dependable fastening is required. Choose quality, choose longevity—choose the right screws for your next project.

Performance Benefits

All builders and tradespeople recognise the importance of using reliable fastening solutions in their projects. Fibre cement to timber steel screws are designed to deliver exceptional performance, providing secure connections that enhance the longevity and strength of your structures. These screws feature a robust gash point design that assures penetration without splitting, making them ideal for a variety of applications in construction, from decking and roofing to framing and cladding.

Structural Integrity

Structural Integrity

Benefits include outstanding tensile strength and resistance to shear forces, ensuring that your constructions remain stable and durable over time. With these screws, you can maintain the integrity of your structures, knowing they will withstand the demands of different trade applications, whether in flooring or roofing work.

Weather Resistance

Integrity in your fasteners is important for outdoor applications. Fibre cement to timber screws are specifically engineered to resist corrosion and degradation from environmental factors, ensuring long-lasting performance regardless of the weather conditions.

Structural integrity is vital for any construction project, and using fibre cement to timber screws significantly enhances your work’s resilience against the elements. These screws possess a strong weather-resistant coating, expertly formulated to protect against rust and corrosion, providing durability even in the harshest climates. For tradespeople involved in outdoor projects, such as roofing and decking, this strong weather resistance feature is indispensable, ensuring that your installations maintain their strength and appearance over time. This helps you deliver reliable, high-quality results that meet the expectations of your clients.

Cost-Effectiveness and Longevity

Once again, investing in fibre cement to timber screws offers outstanding cost-effectiveness and longevity, making them an necessary choice for durable construction. These screws are designed to withstand the test of time, delivering exceptional holding strength and reducing the frequency of replacements. With their reliability, you can ensure that your projects stand firm against the elements, providing peace of mind while saving on long-term costs.

Initial Investment vs. Long-term Value

Below the surface cost of your initial purchase, it’s vital to analyse the long-term value these screws bring to your projects. While the upfront investment may appear higher than standard screws, their unmatched durability and reduced maintenance needs result in significant savings over time. By choosing fibre cement to timber screws, you ensure a more reliable construction that minimises future expenses related to repairs and replacements. Additionally, when considering fibre cement vs timber screws, it’s essential to recognize the enhanced performance these screws provide in various environmental conditions. Their resistance to corrosion and wear makes them a preferred choice for projects exposed to moisture or extreme weather. Ultimately, the long-term investment in quality screws pays off by ensuring structural integrity and peace of mind for years to come.

Maintenance Requirements

Maintenance Requirements

Requirements for upkeep are minimal when using fibre cement to timber screws, thanks to their robust corrosion resistance and exceptional strength. This feature allows builders like you to focus on other critical project tasks rather than constant upkeep.

Even with exposure to various environmental conditions, these screws maintain their integrity, significantly reducing the risk of problems like rust or loosening. This dependability provides peace of mind for builders, enabling you to deliver higher-quality work without the headache of frequent repairs. With features tailored to the needs of tradespeople—such as easy installation and long-lasting performance—fibre cement to timber screws enhance your workflow, proving indispensable for construction, carpentry, and roofing projects alike. Choose these screws, and enjoy the advantage of enduring strength in every build.

Safety Standards and Compliance

Not adhering to safety standards can have severe repercussions in construction. Using Fibre Cement to Timber Screws ensures that your projects meet stringent safety regulations, aligning with compliance requirements that protect both workers and the integrity of the structure. With reliable gash point design, these screws penetrate materials cleanly, dramatically reducing the risk of accidents caused by malfunctioning fasteners, thus promoting a safer work environment.

Building Code Requirements

By understanding local building codes, you can select Fibre Cement to Timber Screws that comply with the necessary standards. These screws are made to withstand diverse weather conditions, ensuring both durability and reliability in your construction projects. Compliance with these codes not only guarantees safety but also enhances the value of your work.

Industry Certifications

Standards across the construction sector are ever-evolving, and having the right industry certifications can set your work apart. Fibre Cement to Timber Screws often come with certifications that ensure they meet specific performance criteria, such as tensile strength and corrosion resistance.

And, possessing industry certifications means you can trust that Fibre Cement to Timber Screws have been rigorously tested to withstand the demands of construction work. This certification assures you that the screws provide long-lasting performance, even in harsh conditions, making them an ideal choice for trades such as carpentry and roofing. Whether you’re fastening large sheets of fibre cement to timber frames or requiring a dependable solution for flooring installations, having compliant and certified screws helps ensure your project’s success and safety, allowing you to work confidently.

Summing up

With these considerations, Fibre Cement to Timber Steel Screws are important for durable construction due to their robust design and longevity. When you choose these screws, you benefit from superior holding power and exceptional resistance to corrosion, making them ideal for long-lasting applications in external environments. These features are particularly advantageous for builders and tradespeople, as they ensure reliable performance across various tasks, including those faced by carpenters and roofers, where secure fastening is paramount. Your work can achieve increased efficiency and reduced maintenance concerns, allowing you to focus on delivering high-quality results.

Fibre Cement to Timber Steel Screws FAQ

Q: Why are Fibre Cement to Timber Steel Screws necessary for durable construction?

A: Fibre Cement to Timber Steel Screws are designed specifically to provide a strong and reliable connection between fibre cement boards and timber structures. These screws are made from high-quality steel, ensuring they can withstand the demands of various construction environments. Their unique gash point design allows for easier penetration into tough materials like fibre cement, reducing installation time and ensuring a secure fit. This combination of strength and efficiency makes them indispensable for builders looking to guarantee longevity in their projects. In addition to their robust construction, these screws adhere to stringent fibre cement screw specifications that ensure optimal performance and compatibility with various materials. Builders can rely on these screws not only for structural integrity but also for consistent quality across different projects. By choosing the right screws that meet these specifications, contractors can maximize the durability and stability of their installations.

Q: How do these screws benefit tradespeople in their work?

A: Builders and tradespeople benefit significantly from using Fibre Cement to Timber Steel Screws due to their ease of use and durability. The screws are engineered to minimize splitting in timber and prevent shearing, which is often a concern when working with harder materials. This reliability means tradespeople can focus on their craft without worrying about potential failures in their connections. Additionally, the time saved during installation, thanks to their penetrating capabilities, allows for a more efficient workflow, giving professionals the opportunity to complete more projects within tighter timelines.

Q: In which applications are Fibre Cement to Timber Steel Screws most effective?

A: These screws are highly effective in various applications, especially where fibre cement boards are used alongside timber structures, such as in roofing work, wall cladding, and flooring installations. Carpenters and joiners find these screws ideal for ensuring that frameworks are secure, while roofing contractors appreciate their strength and resilience against adverse weather conditions. Furthermore, plasterers and painters can rely on the stability provided by these screws, which contributes to the longevity and aesthetic appeal of the finished work.

Product Description

Fibre Cement to Timber Steel Screws are specifically engineered fasteners designed to meet the demanding requirements of construction professionals. Their robust composition makes them the go-to choice for builders who seek long-lasting solutions in a variety of applications. With a sharp gash point that penetrates fibre cement effortlessly, these screws ensure a secure and dependable bond with timber, an necessary feature for tasks where structural integrity is paramount.

Construction workers, particularly those in roofing and cladding, find these screws indispensable. When fastening fibre cement boards to timber battens, builders can rely on these fasteners to withstand the elements while maintaining durability over time. The enhanced grip and resistance to splitting make them a favourite among carpenters and joiners, who require dependable materials that simplify their work processes and result in a high-quality finish.

This product also offers several advantages tailored to the needs of tradespeople. The screws are designed to prevent corrosion, which is crucial for longevity, particularly in external applications. Their compatibility with power tools allows for quick and efficient installation, enabling tradespeople to save valuable time on site. Additionally, these screws support a cleaner and more professional appearance in the final installation, greatly appreciated by painters and decorators who seek perfect finishes.

Ultimately, Fibre Cement to Timber Steel Screws are an necessary asset for construction professionals. Their resilience, ease of use, and adaptability across various trades make them a must-have in any toolbox. By investing in these high-quality screws, builders can ensure their projects are built to last, meeting the high standards expected in today’s competitive marketplace.

Mechanical Properties and Load Requirements

Mechanical Properties and Load Requirements Thread Design and Holding Power

Thread Design and Holding Power Structural Integrity

Structural Integrity Maintenance Requirements

Maintenance Requirements