Over the next few years, concrete masonry screws will become increasingly important in your construction and DIY projects. With advancements in materials and technology, you’ll need to be aware of the latest design improvements and safety considerations when using these fasteners. Understanding the evolving landscape of concrete masonry screws will not only enhance your construction skills but also ensure you’re using the best practices, helping you achieve stronger and safer installations in 2025 and beyond.

Key Takeaways:

- Concrete masonry screws are set to evolve in 2025, featuring improved designs and materials that enhance their performance and durability.

- Understanding the correct installation techniques and load requirements will be crucial to maximise the effectiveness of these screws in various construction projects.

- As regulations and standards may change, staying updated on safety certifications and industry best practices for concrete masonry screws will be imperative for professionals in the field.

The Technological Evolution of Concrete Masonry Screws

The Technological Evolution of Concrete Masonry Screws

The landscape of concrete masonry screws is undergoing a significant transformation, driven by innovations that enhance durability, efficiency, and performance. As the construction industry embraces modern technology, you can expect these screws to offer improved anchorage properties, reduced installation times, and greater resistance to environmental factors. Adaptations in design, coupled with user feedback, are paving the way for more advanced fastening solutions that cater to a wide range of applications.

Innovations in Material Science

Recent advancements in material science have led to the development of concrete masonry screws made from high-strength alloys and corrosion-resistant coatings. These materials enhance the screws’ life span and performance, enabling better performance in harsh conditions. Engineers have begun to experiment with composite materials, offering the prospect of lighter, even more resilient fastening options for various environments.

Advancements in Manufacturing Techniques

The production of concrete masonry screws has seen remarkable advancements, particularly with the introduction of automated machining processes and precision engineering. These techniques not only improve uniformity and consistency in screw dimensions but also significantly enhance the efficiency of production. Moreover, the incorporation of computer-aided design (CAD) allows for the fine-tuning of screw geometry, resulting in superior performance characteristics tailored for specific applications, such as enhanced thread profiles and optimised tip designs.

Utilising advanced manufacturing techniques also means that production waste is minimised, benefiting both the environment and your project budget. For instance, 3D printing technologies are now being explored, particularly when creating prototypes or small production runs, allowing for rapid testing and iterations in screw design. As these methods become more refined and widely adopted, the possibilities for custom solutions that match your specific project requirements greatly increase. You’ll find that the integration of state-of-the-art machinery not only enhances quality but also leads to faster turnaround times, ensuring you stay on schedule with your construction projects.

The Economic Landscape in 2025

As you navigate the economic landscape of 2025, emerging trends will shape your decisions regarding concrete masonry screws. A focus on sustainability and efficiency in construction means you’ll find increased demand for high-performance products that promise longevity and reliability. With ongoing innovations and a shift towards environmentally friendly materials, these changes will significantly influence your purchasing choices and project timelines.

Price Trends and Market Drivers

Price fluctuations for concrete masonry screws will largely stem from the rising costs of raw materials and evolving manufacturing processes. As competition heightens, you’ll observe a shift towards affordable solutions without compromising quality. Market drivers such as labour shortages and increased demand for swift construction solutions will further impact pricing, compelling you to stay informed about the best available options.

The Impact of Global Supply Chains

The interconnected nature of global supply chains will profoundly affect your access to concrete masonry screws in 2025. Disruptions caused by geopolitical tensions or natural disasters can lead to delays or increased costs, forcing you to adapt your sourcing strategies. The reliance on diverse regional suppliers will create both opportunities and challenges, highlighting the necessity of flexibility in your procurement processes.

In 2025, global supply chains will continue to evolve with increasing attention to transparency and sustainability. When sourcing concrete masonry screws, you may prioritise suppliers who demonstrate ethical practices and support local economies. Integrated digital platforms will facilitate better tracking of products, enabling you to anticipate shortages and adjust orders more effectively. As you embrace these changes, maintaining strong relationships with suppliers will be necessary in ensuring a steady flow of high-quality materials, allowing you to remain competitive in the ever-changing market landscape.

New Applications and Industry Trends

New Applications and Industry Trends

The versatility of concrete masonry screws has led to their adoption across various industries, responding to the demands of modern construction methods. With the rise of smart building technologies and modular construction techniques, these screws are increasingly seen as important components in ensuring strength and durability in structures. This evolution is not just about performance; it’s also about adapting to new materials and methods that improve efficiency and reduce costs.

Emerging Sectors Utilising Concrete Masonry Screws

Innovative sectors such as renewable energy, prefabricated housing, and disaster relief construction are now leveraging concrete masonry screws. For instance, the installation of solar panel mounts increasingly requires secure anchoring to concrete surfaces, where these screws excel. Their ability to provide a quick and reliable solution aligns perfectly with the fast-paced demands of emerging industries.

Sustainability and Environmental Considerations

As sustainability becomes a core focus in construction, concrete masonry screws are adapting to meet eco-friendly standards. Manufacturers are exploring ways to reduce the environmental impact associated with production and disposal, utilising recycled materials and sustainable practices. These trends not only enhance your project’s green credentials but also contribute to lower lifecycle costs.

One significant innovation in this area is the shift towards screws made from recycled steel, which reduces energy consumption during production. Furthermore, the development of coatings that extend the lifespan of the screws helps minimise waste by reducing the frequency of repairs or replacements. As you consider your projects in the coming years, opting for sustainable fasteners could lead to significant environmental benefits, aligning your work with global goals for sustainability while enhancing overall project efficiency.

Best Practices for Installation and Usage

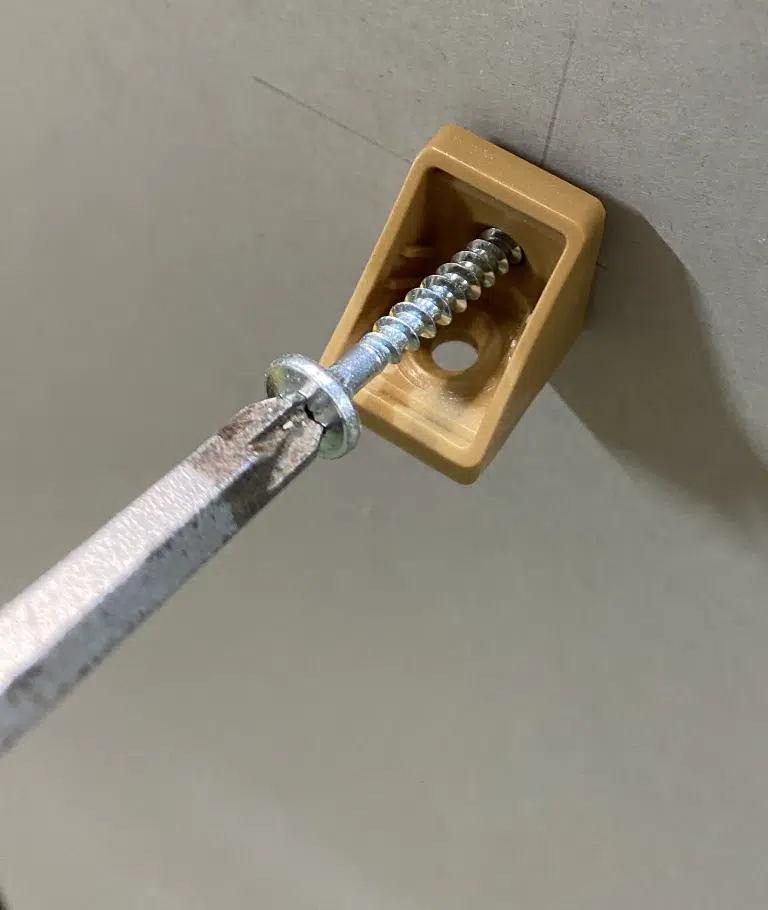

Ensuring the successful installation of concrete masonry screws hinges on following best practices tailored to your specific project. Begin by selecting the correct screw size for the concrete you’re working with, ideally referencing the manufacturer’s guidelines. Always pre-drill pilot holes to the appropriate depth and diameter to prevent cracking and excessive wear on your tools. Additionally, maintaining the necessary torque specifications when driving the screws will enhance holding power and integrity of the installation.

Tools and Techniques for Optimal Performance

Amping up performance during installation requires the right tools and techniques at your disposal. Invest in a quality rotary hammer drill with a suitable masonry bit, as this combination ensures efficient drilling without damaging your screws. Utilise an impact driver to provide consistent torque when driving screws, and consider using a depth stop to achieve precise embedment. These tools will not only save time but also enhance the overall reliability of your installations.

Common Pitfalls and Solutions

Common Pitfalls and Solutions

Several common pitfalls can undermine your efforts with concrete masonry screws. Oversized or incorrectly positioned pilot holes can lead to weak fastening, while inadequate driving torque can result in screws loosening over time. Additionally, neglecting to clean out dust and debris from drilled holes may hinder screw performance. Address these issues by double-checking pilot hole sizes and ensuring your driving technique is aligned with the screw’s specifications.

When addressing common pitfalls, being aware of the typical mistakes made can save you time and frustration. For instance, always ensure that you thoroughly clean out holes after drilling; this simple act can significantly improve holding strength. If you find screws continually loosening, reassess your driving torque or consider using anaerobic adhesives designed for masonry applications to create an even more secure bond. Keeping a checklist of these potential issues during your projects will streamline your installation process and enhance the durability of your results.

Future Predictions and Expert Insights

As we look towards 2025 and beyond, the landscape of concrete masonry screws is expected to evolve remarkably. Experts predict a shift towards more sustainable materials, reducing the environmental footprint of construction without compromising strength. Increased automation in manufacturing processes might further enhance consistency and performance, propelling the industry into a new era of precision. Additionally, advanced coatings and finishes will make these screws not only more durable but also resistant to corrosion and wear, ensuring they meet the demands of various climate conditions.

Trends Shaping the Industry in the Coming Years

Anticipated trends include a rise in eco-friendly materials, driven by stringent regulations and consumer demand for sustainability. You will likely notice an increase in innovative fastening solutions that cater to diverse construction methods. Technological advancements such as 3D printing are also set to revolutionise screw manufacturing, allowing for custom solutions and detailed designs tailored specifically for bespoke projects.

Interviews With Industry Leaders

Insights from industry leaders reveal an optimistic outlook for the concrete masonry screw market. Many express a commitment to research and development, focusing on innovative materials and designs that enhance screw performance and sustainability. Leaders have noted the increasing demand for projects with minimal environmental impact and forecasted that future products will encompass both strength and eco-consciousness. Their expert opinions highlight the necessity for collaboration among manufacturers, builders, and researchers to drive the industry forward.

To wrap up

With this in mind, as you navigate the landscape of concrete masonry screws in 2025, it is necessary to stay informed about advancements in materials and technologies. Understanding the specifications and applications of different types will enhance your projects’ quality and durability. By prioritising proper installation techniques and selecting the right screws for your tasks, you can ensure optimal results in your construction endeavours. Embracing these insights will undoubtedly empower you to make more informed decisions in your building projects.

FAQ

Q: What are concrete masonry screws and how do they work?

A: Concrete masonry screws are specialised fasteners designed to anchor materials to concrete or masonry surfaces. They typically feature a unique thread design that allows them to create a secure hold in hard surfaces without the need for pre-drilling in many cases. When driven into the concrete, the threads cut into the material, providing superior grip and stability.

Q: What should I consider when choosing concrete masonry screws for my project in 2025?

A: When choosing concrete masonry screws, consider factors such as the length and diameter of the screw, the material composition (e.g., carbon steel or stainless steel), and the specific weight and type of load they will bear. Additionally, ensure compatibility with any anchors or fittings you may be using, as well as environmental factors such as exposure to moisture, which may influence corrosion resistance.

Q: Are there any advancements in concrete masonry screw technology expected in 2025?

A: Yes, advancements are anticipated in areas such as materials science and manufacturing processes. Innovations may include improved corrosion-resistant coatings, enhanced thread designs for better grip, and eco-friendly materials that reduce environmental impact. These advancements aim to provide greater strength and durability while also simplifying installation procedures.

Q: How can I ensure proper installation of concrete masonry screws?

A: To ensure proper installation, first select the appropriate screw length for your application and ensure that the drill is suitable for concrete. Pre-drilling may be required for larger sizes. Use a hammer drill and apply consistent pressure when driving the screw. It is also advisable to follow supplier guidelines and use the correct torque settings to avoid damaging the screw or the substrate.

Q: What are some common applications for concrete masonry screws in 2025?

A: Concrete masonry screws can be used in various applications including securing fixtures, installing shelving units, attaching brackets for structural elements, and in construction for fastening wall panels or cladding. They are also popular in renovation projects where reliability and ease of installation are critical.

The Technological Evolution of Concrete Masonry Screws

The Technological Evolution of Concrete Masonry Screws New Applications and Industry Trends

New Applications and Industry Trends Common Pitfalls and Solutions

Common Pitfalls and Solutions