Concrete Masonry Screws (Self-Tapping, No Plugs Needed, ZYP Finish)

No wall plugs required: Self-tapping masonry thread bites directly into concrete and brick for quicker installs.

Stronger, cleaner fixings: Excellent pull-out resistance when fitted into a correctly sized pilot hole.

Time-saving, trade-ready kit: Supplied with a T30 TX bit so you can start fixing straight away.

Corrosion resistance for indoor/outdoor use: Zinc Yellow Passivated (ZYP) finish helps resist rusting in typical exterior environments.

Versatile across substrates: Ideal for concrete, dense brick, blockwork and solid masonry (always test on brittle substrates).

Free shipping on orders over £60

- No-Risk Money Back Guarantee!

- No Hassle Refunds

- Secure Payments

Concrete Masonry Screws – Fast, Plug-Free Fixing with High Pull-Out Strength (Zinc Yellow Passivated + T30 Bit Included)

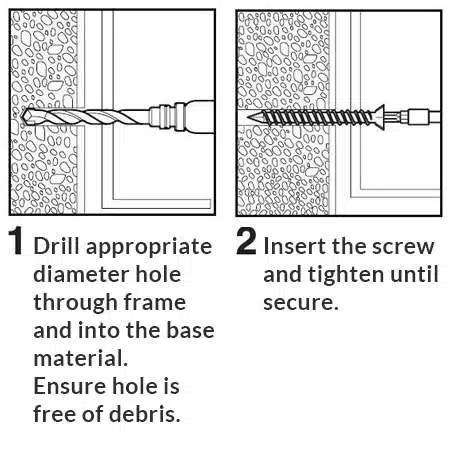

How to Fit (Quick Guide)

1. Mark & drill a pilot hole into the masonry (typically 6.0–6.5 mm depending on screw diameter and substrate hardness).

2. Clear dust from the hole (blow out/brush out) for best grip and pull-out resistance.

3. Drive the screw using the supplied T30 TX bit until the fixing is snug—do not overtighten.

4. Check alignment and loading. For heavier loads, use multiple fixings and correct edge distances.

These Concrete Masonry Screws are designed for fast, reliable fixing into masonry without the need for wall plugs. Built with a high-performance, self-tapping thread, they cut their own mating thread into a pre-drilled pilot hole (commonly 6.0–6.5 mm), creating a strong mechanical interlock with the substrate. The result is a clean, professional installation with excellent holding power and reduced installation time—perfect for fitters, builders, maintenance teams and serious DIYers.

What Concrete Masonry Screws are best for

If you regularly fix timber battens, metal brackets, frames or services into masonry, these screws provide a dependable solution where speed and consistency matter. They’re particularly useful for:

– Timber-to-masonry fixing (e.g., battens, rails, packers, door linings)

– Metal-to-masonry fixing (e.g., brackets, angle iron, strut channel, supports)

– Electrical and plumbing installs (e.g., clips, conduit saddles, trunking, pipe brackets)

– General building and maintenance where plug-free fixing reduces steps and callbacks

Key Concrete Masonry Screws features & specifications

– Self-tapping masonry thread: Engineered to form a secure connection inside masonry for high load performance.

– Pilot-hole installation: Works in a properly drilled hole—this is critical for best pull-out resistance and to reduce the risk of cracking softer masonry.

– TX (Torx) drive: Uses a T30 bit for improved torque transfer and reduced cam-out versus pozi drives.

– Zinc Yellow Passivated finish (ZYP): A protective coating that helps improve corrosion resistance for typical exterior exposure and internal damp-prone areas.

– No plug required: Fewer components, faster fitting, and cleaner stock management.

> Installation tip (important): The correct drill diameter and hole depth directly affect performance. Drill to the recommended size, go deep enough to allow dust clearance, and always clean out the hole before fitting.

Substrates & performance notes

These masonry screws are suitable for concrete, solid brick, blockwork and other dense masonry materials. In softer or brittle substrates (older brickwork, weak block, crumbly mortar), performance can vary—consider moving the fixing position, reducing torque, or using an alternative system if the substrate is not sound.

Technical standards

Where required for regulated projects, fixings should be selected in line with project specifications and approvals (e.g., ETA/CE where applicable). If you need compliance information for a specific job (structural or overhead load), confirm required standards with the project engineer/specifier and choose a certified anchor system accordingly.

Bottom line: These concrete masonry screws are the go-to option when you want speed, strength and simplicity—drill, drive, done—no plugs needed.

Concrete Masonry Screws Features

– Self-tapping masonry thread → Creates a firm mechanical bond for strong fixings without plugs.

– Plug-free installation → Fewer steps; faster fitting and reduced snagging on site.

– T30 TX drive + bit included → Better grip, less rounding, easier high-torque driving.

– Zinc Yellow Passivated (ZYP) coating → Improved protection against corrosion for longer service life.

– Suitable for multiple substrates → One fixing type for concrete, brick and blockwork (subject to site testing).

Concrete Masonry Screws: People Ask Questions & Answers People Ask (FAQ)

Q1: Do I need wall plugs with these concrete masonry screws?

A: No. They’re designed for plug-free fixing—you drill a pilot hole, then the screw cuts its own thread into the masonry.

Q2: What size pilot hole should I drill?

A: Commonly 6.0–6.5 mm, depending on the screw size and substrate. Always follow the product’s recommended drill diameter and test in your base material for best pull-out resistance.

Q3: Can I use these screws in brick as well as concrete?

A: Yes—these screws are typically suitable for concrete, brick and blockwork. In older or softer brick, use care (avoid edges, don’t overtighten) and test the holding strength.

Q4: Are they suitable for outdoor use?

A: The Zinc Yellow Passivated finish offers good general corrosion resistance for many exterior jobs. For highly corrosive environments (coastal, chemical exposure), consider a higher-grade corrosion-resistant fixing (e.g., stainless options).

Q5: What driver bit do I need?

A: These use a T30 TX (Torx) drive. A T30 bit is included for convenience.

Concrete Masonry Screws Common Uses

– Fixing timber battens to concrete walls for plasterboard/dry lining

– Securing cable trunking and conduits to masonry

– Mounting pipe clips and brackets to brickwork

– Installing frames, rails, brackets and supports without wall plugs

– General site fixing where speed and reliable pull-out strength matter

| ☁ Cloud Rating | Approx. Salt Spray Hours* | Description |

|---|---|---|

| ☀ 1 Cloud | < 100 hrs | Indoor / fully sheltered use |

| 🌤 2 Clouds | ~100 – 500 hrs | Indoor + sheltered outdoor |

| 🌦 3 Clouds | ~500 – 1,000 hrs | General outdoor use with specialist coating |

| 🌧 4 Clouds | ~1,000 + hrs | A2 stainless steel – exterior use inland |

| ⛈ 5 Clouds | 1,000 + hrs / “marine grade” | A4 stainless – coastal / high-exposure use |

*Approximate values based on typical corrosion testing standards (salt spray testing to first rust).

Marc’s Cloud Rating – Always First 4 Fixings Corrosion Resistance Guide

Choosing the right screw or fixing is all about matching it to the environment — especially when it comes to

corrosion resistance.

That’s why at Always First 4 Fixings, we’ve created a quick and simple way to help you pick the perfect product for any job:

☁️ Marc’s Cloud Rating

Each fixing on our site is given a Cloud Rating (☀️ to ⛈️) — your easy guide to how well it stands up to the weather. The more clouds, the more corrosion-resistant the fixing!☀️ 1 Cloud – Indoor / Covered Outdoor Use

Designed for: Dry indoor environments or outdoor areas completely covered from the elements. Perfect for internal projects, garages, lofts, or sheltered spaces where moisture exposure is minimal.🌤️ 2 Clouds – Indoor / Sheltered Outdoor Use

Designed for: Indoor use or external areas with some protection from direct rain or weather. Ideal for porches, under decking, or covered outdoor structures where occasional moisture may occur.🌦️ 3 Clouds – General Outdoor Use

Designed for: Both indoor and outdoor use. Typically features specialist corrosion-resistant coatings and undergoes 500–1000 hours salt spray testing. Great for garden furniture, fencing, sheds, or exposed outdoor areas not constantly hit by sea air.🌧️ 4 Clouds – A2 Stainless Steel

Designed for: Tough external environments. Made from A2 stainless steel, these screws are durable and weather-resistant — ideal for outdoor projects more than 10 miles inland. Reliable for all general external applications and completely fine for indoor use too.⛈️ 5 Clouds – A4 Marine Grade Stainless Steel

Designed for: The harshest, most demanding environments. Made from A4 stainless steel (marine grade), these fixings offer maximum corrosion resistance — perfect for coastal areas, marine use, or anywhere exposed to salt air and constant moisture. The “big daddy” of weatherproof fixings — unbeatable outdoors, worry-free indoors.How to Use Marc’s Cloud Rating

You’ll find the Cloud Rating (☀️–⛈️) shown on each product across our website. Simply match the rating to your project’s environment and know exactly how your fixing will perform — rain or shine! Always First 4 Fixings – Helping You Choose with Confidence.| Size | 210/212mm, 40/42mm, 50/52mm, 60/62mm, 72/75mm, 80/82mm, 90/92mm, 100/102mm, 110/112mm, 120/122mm, 130/132mm, 140/142mm, 150/152mm, 180/182mm, 200/202mm |

|---|

Add a review

You must be logged in to post a review.

Shipping Policy

At Always First 4 Fixings, we know that your projects rely on fast, dependable delivery. That’s why we offer flexible UK shipping options designed for tradespeople and businesses:

Fast Dispatch: Orders are processed and dispatched within 24 hours on working days.

Free shipping on all orders over £60 (UK mainland).

Express options available to keep your jobs moving.

Click & Collect: Order online and pick up at your convenience (if applicable).

Reliable Couriers: We use trusted UK carriers to ensure your fixings and fasteners arrive on time.

You’ll receive tracking details as soon as your order leaves our warehouse. Delivery times may vary depending on location and availability, but we work hard to get your order to you as quickly as possible.

At Always First 4 Fixings, we know that your projects rely on fast, dependable delivery. That’s why we offer flexible UK shipping options designed for tradespeople and businesses:

Fast Dispatch: Orders are processed and dispatched within 24 hours on working days.

Free shipping on all orders over £60 (UK mainland).

Express options available to keep your jobs moving.

Click & Collect: Order online and pick up at your convenience (if applicable).

Reliable Couriers: We use trusted UK carriers to ensure your fixings and fasteners arrive on time.

You’ll receive tracking details as soon as your order leaves our warehouse. Delivery times may vary depending on location and availability, but we work hard to get your order to you as quickly as possible.

Reviews

There are no reviews yet.