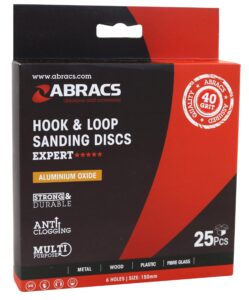

Over time, you may find that the quality of your sanding tools significantly impacts the results of your projects. With Abracs hook and loop sanding discs, you can achieve a superior finish with ease. These discs are designed for quick changes and maximum efficiency, ensuring you spend less time switching tools and more time on your work. By choosing Abracs, you enhance your sanding experience, making it effortless and effective, whether you’re a DIY enthusiast or a professional tradesperson. These discs also come in a variety of grits, making them suitable for every stage of sanding, from rough shaping to fine finishing. One of the top reasons for choosing Abracs discs is their durability, allowing you to tackle tougher jobs without the worry of wear and tear. Additionally, their excellent dust extraction capabilities help create a cleaner work environment, ensuring you can focus on the task at hand.

Key Takeaways:

- Hook and loop sanding discs provide quick and easy attachment and removal, enhancing efficiency during projects.

- High-quality Abracs discs are designed for longevity, ensuring consistent performance and reducing the need for frequent replacements.

- The variety of grain options available caters to different materials and finishes, making them versatile for various applications.

Understanding Hook & Loop Sanding Discs

Understanding Hook & Loop Sanding Discs

Hook and loop sanding discs are designed for quick attachment and removal, providing a seamless experience for DIY enthusiasts and professionals alike. This innovative fastening system features tiny hooks on the backing of the disc that securely hold onto a matching loop surface on the sander. The ease of switching discs can save you valuable time during your projects, improving overall workflow and productivity.

What are Hook & Loop Sanding Discs?

Hook and loop sanding discs consist of a circular abrasive material affixed to a backing with a cohesive surface of hooks and loops. This design enables you to quickly replace worn discs without the need for adhesive or tools. Suitable for a variety of sanding applications, these discs are available in different grits to match your specific project requirements.

Advantages over Traditional Sanding Methods

Hook and loop sanding discs offer several advantages over traditional sanding methods, which include efficacy in changing grits, reduced downtime, and enhanced versatility. Since you can easily swap out discs, transitioning between sanding tasks requires minimal effort, allowing for a more streamlined workflow. Furthermore, the consistent backing ensures even pressure during use, resulting in finer finishes.

When using traditional sanding methods, you often deal with cumbersome adhesives or complicated fastening systems that can slow you down. With hook and loop discs, you simply pull off the old disc and attach a new one. This not only saves time but also enhances precision by allowing you to switch between coarse and fine grits seamlessly. Abracs hook and loop discs are specifically crafted to withstand the rigours of heavy use, ensuring that you achieve quality results without unnecessary interruptions. Being able to change out discs so readily means your sanding projects go from laborious to effortless, giving you more time to focus on the finish rather than the process.

The Abracs Advantage

Choosing Abracs brings numerous benefits for your sanding tasks. Their engineered designs and superior materials ensure that you achieve optimal results with minimal effort. Incorporating innovative technology, these sanding discs facilitate a seamless sanding experience, making them a reliable choice for both professionals and DIY enthusiasts alike. With an abracs sanding discs overview, you can easily compare the various options available to suit your specific projects. The versatility of these discs enables them to be effective on multiple surfaces, from wood to metal, providing exceptional value for your investment. As a result, whether you’re tackling a small home improvement task or a large-scale professional job, Abracs sanding discs deliver consistent performance and durability you can trust.

Quality of Abracs Sanding Discs

Abracs sanding discs are crafted using high-quality materials that guarantee exceptional performance. The precision-engineered grits provide a consistent finish, allowing you to achieve the desired surface texture without the hassle of uneven sanding. With Abracs, you can trust that your sanding needs are met with professionalism and quality.

Durability and Longevity

Durability is a hallmark of Abracs sanding discs, designed to withstand the rigours of intensive use. These discs maintain their sanding efficiency over prolonged periods, significantly reducing the frequency of replacements. Their robust construction allows for use on various surfaces, making them a versatile addition to your toolkit.

Investing in Abracs sanding discs means you are choosing longevity. Each disc is formulated to resist wear and tear, enabling you to complete more projects without interruptions for replacements. For instance, users report a decrease in disc consumption by up to 30% compared to lesser brands, highlighting Abracs’ commitment to delivering products that stand the test of time. This extended lifespan not only enhances your productivity but also makes your project handling more economical in the long run.

Choosing the Right Sanding Disc

Choosing the Right Sanding Disc

Selecting the appropriate sanding disc can significantly impact your project’s finish. You need to consider the material you are sanding, the type of finish you desire, and the compatibility with your sander. Each disc has unique features designed for specific applications, so aligning these with your project requirements can enhance efficiency and effectiveness.

Grit Types and Their Applications

The grit type of a sanding disc determines its abrasiveness and suitability for various materials. Coarse grits (40-60) are ideal for initial material removal, while medium grits (80-120) cater to smoothing surfaces. Fine grits (150-220) excel in final finishing and polishing. Understanding these options enables you to choose the right disc for your tasks.

- Coarse grits remove material quickly.

- Medium grits are versatile for various surfaces.

- Fine grits perfect for finishing touches.

- Specialty grits target specific materials.

- Any choice should reflect your project’s demands.

| Grit Type | Typical Use |

| 40-60 | Initial material removal |

| 80-120 | Smoothing surfaces |

| 150-220 | Final finishing |

| Specialty | Targeted applications |

Size and Compatibility Considerations

Your sander’s size and compatibility with sanding discs are vital to achieving the best results. Discs come in various diameters, typically ranging from 125mm to 200mm, so ensure the size matches your specific sander model. A proper fit enhances performance and prevents issues during sanding.

Moreover, consider the mounting method of the sanding discs, whether hook and loop or adhesive. Hook and loop discs are more convenient, allowing for easy and quick changes. Ensure the backing is compatible with your sander’s pad. Always check your sander’s specifications to avoid compatibility issues, as using correctly sized and fitted discs results in optimal sanding efficiency and finish quality.

Tips for Effective Sanding

- Choose the right grit for your material.

- Keep your sanding surface clean to avoid clogging.

- Sand with the grain for a smoother finish.

- Apply even pressure to prevent surface damage.

- Change discs regularly for consistent results.

Knowing these tips can help you achieve a superior finish on your projects.

Surface Preparation Best Practices

Before sanding, ensure the surface is free from dust, grease, and other contaminants. Clean the area thoroughly, and consider using a degreaser or damp cloth for stubborn residues. Allow the surface to dry completely before you begin sanding. By starting with a well-prepared surface, you’ll enhance the effectiveness of your sanding efforts and prolong the life of your Abracs discs.

Techniques for Optimal Results

Techniques for Optimal Results

To maximise the outcome of your sanding project, incorporate techniques such as overlapping your sanding passes and varying the speed of your sander. Start with a coarser grit to remove material quickly, then gradually transition to finer grits for a polished finish. Additionally, using the right backing pad compatible with your Abracs discs will ensure the best adhesion and performance.

For optimal results, experiment with the speed settings of your sander to find the sweet spot that aligns with your material. Maintain a steady motion, allowing the disc to do its job without excessive pressure, which can lead to uneven surfaces. Transitioning through grits should be systematic; start low at around 80-grit for removing imperfections, then progressively move to 120-grit and finer until the desired smoothness is achieved. This layered approach leads to an immaculate finish, ideal for both DIY enthusiasts and professional craftsmen.

Common Mistakes to Avoid

Even experienced users can fall victim to common mistakes that hamper the efficiency of their sanding tasks. Misjudging the grit of sanding discs or neglecting the importance of proper pressure can lead to subpar finishes. Additionally, overlooking maintenance practices, such as cleaning the discs regularly or storing them properly, can significantly shorten their lifespan. Staying aware of these pitfalls will ensure you maintain high standards in your projects.

Misusing Sanding Discs

Misusing Sanding Discs

Using sanding discs incorrectly can lead to unsatisfactory results and wasted materials. For instance, employing a coarse grit disc on delicate surfaces may cause damage, while using fine grits for heavy-duty jobs would take unreasonably long to achieve the desired effect. Always match the disc’s grit to the specific requirements of your task for optimal results.

Over-sanding and Its Effects

Over-sanding can be detrimental to your projects, creating uneven surfaces or diminishing the integrity of the material. This occurs when excessive pressure or prolonged sanding on a single area leads to material wear beyond the intended finish. You might find yourself needing to repair or replace surfaces, which wastes time and resources.

Over-sanding not only degrades the material but can also adversely affect the finish quality. For instance, wood can become excessively smooth, losing the texture necessary for a good stain or finish to adhere properly. In metal surfaces, over-sanding might lead to thinning, which compromises strength and durability. To mitigate this, use a light touch and change discs to match your project’s progress, ensuring you achieve a balanced and professional finish without compromising material integrity.

To wrap up

Considering all points, utilising Abracs hook and loop sanding discs allows you to achieve superior results in your projects with minimal effort. Their design ensures quick disc changes, enhancing productivity and efficiency in any task. You can rely on their consistent performance and durability, making your sanding experience smoother and more effective. By choosing Abracs, you invest in quality that enhances your craftsmanship and helps you achieve the finish you desire.

FAQ

Q: What are Hook & Loop sanding discs?

A: Hook & Loop sanding discs are abrasive discs that utilise a velcro-style backing, allowing for quick and easy attachment and removal from sanding pads. They provide convenience and efficiency in various sanding tasks.

Q: What advantages do Abracs Hook & Loop sanding discs offer?

A: Abracs Hook & Loop sanding discs are designed for durability and performance. They feature high-quality materials that provide long-lasting abrasion, a range of grit options for different finishes, and a reliable attachment system that minimises disc slippage. Users consistently praise the efficiency and effectiveness of these discs in various abrading tasks. For those looking to understand the performance and longevity firsthand, numerous abracs sanding discs review articles highlight their ease of use and superior finish. This makes them a go-to choice for both professionals and DIY enthusiasts alike.

Q: How do I choose the right grit for my project?

A: Selecting the right grit depends on the material and the desired finish. Coarse grits (40-80) are suitable for heavy material removal, medium grits (120-180) work well for general sanding and smoothing, while fine grits (220 and above) are ideal for finishing touches and polishing.

Q: Can I use Abracs sanding discs on different types of surfaces?

A: Yes, Abracs sanding discs are versatile and can be used on various surfaces including wood, metal, plastics, and composites. Always choose the appropriate grit level for the specific material to achieve optimal results.

Q: How should I store my Hook & Loop sanding discs?

A: Store Hook & Loop sanding discs in a cool, dry place away from direct sunlight and moisture. Keeping them flat and in their original packaging will help preserve their quality and prolong their lifespan.

Understanding Hook & Loop Sanding Discs

Understanding Hook & Loop Sanding Discs Choosing the Right Sanding Disc

Choosing the Right Sanding Disc Techniques for Optimal Results

Techniques for Optimal Results Misusing Sanding Discs

Misusing Sanding Discs