It’s important to equip yourself with the right tools when installing metal speed plug plasterboard fixings. These fixings offer a robust solution for hanging items securely on plasterboard walls, but the success of your installation depends significantly on your choice of tools. You’ll need tools that ensure a precise fit and prevent damage to your plasterboard, allowing you to achieve a professional finish. In this guide, you’ll discover the tools that will enhance your installation process, ensuring safety and efficiency throughout.

Key Takeaways:

- Understanding Metal Speed Plugs: It’s vital to recognise the advantages of using metal speed plugs for secure plasterboard fixing.

- Tool Selection: Choosing appropriate tools, such as a drill and screwdriver, enhances the efficiency of the installation process.

- Drill Settings: Adjust drill settings to avoid damaging the plasterboard while ensuring a snug fit for the metal speed plugs.

- Pre-Drilling: Pre-drilling the holes can significantly improve the ease of installation and the overall finish.

- Safety Considerations: Always prioritise safety by wearing protective gear and ensuring the work area is clear of hazards.

Understanding Metal Speed Plugs

For anyone involved in plasterboard installation, knowing about metal speed plugs is necessary. These innovative fixings offer a reliable solution for securing objects to walls, ensuring a strong hold for various applications. Designed for efficiency and effectiveness, they enable you to work with ease and confidence, facilitating the installation of items in both residential and commercial settings.

What are Metal Speed Plugs?

Between traditional wall plugs and advanced fixings, metal speed plugs stand out due to their unique design and functionality. They are typically made from durable metal and feature a mechanism that allows for swift installation in plasterboard, providing a stable anchor point for attaching shelves, cabinets, and other fixtures.

Between traditional wall plugs and advanced fixings, metal speed plugs stand out due to their unique design and functionality. They are typically made from durable metal and feature a mechanism that allows for swift installation in plasterboard, providing a stable anchor point for attaching shelves, cabinets, and other fixtures.

Benefits of Using Metal Speed Plugs

Plugs like these offer numerous advantages, including enhanced load-bearing capacity and resistance to wear. They significantly reduce installation time compared to conventional methods, enabling a quicker project turnaround. Their robust construction ensures a reliable hold, making them suitable for heavy-duty applications.

Consequently, using metal speed plugs not only maximises the strength of your fixings but also offers peace of mind, knowing your installations are secure. They minimise the risk of failure, which can lead to accidents or damage. The versatility of these plugs means you can confidently use them in various settings, from domestic projects to professional builds, ensuring your work stands the test of time.

Essential Tools for Installation

You will need to equip yourself with the right tools to successfully install Metal Speed Plug Plasterboard Fixings. This ensures an effective and efficient application. A solid toolkit not only speeds up the installation process but also guarantees a secure fit, helping to avoid any mishaps. Selecting high-quality tools can make a significant difference in your work.

Types of Tools Required

Installation depends on using the correct tools, which can be categorised as follows:

| Hand Tools |

|

| Power Tools |

|

This overview gives you the necessary tools for a successful installation of Metal Speed Plug Plasterboard Fixings.

Safety Equipment Considerations

An installation process should always prioritise your safety by using the appropriate safety equipment. Proper personal protective equipment (PPE) will help mitigate risks and ensure your well-being on the job. Items like safety goggles, gloves, and ear protection are crucial. Make sure they fit comfortably to avoid distractions while you work.

Understanding the importance of wearing safety equipment cannot be underestimated. Wearing protective goggles shields your eyes from dust particles and debris, while gloves protect your hands from sharp edges and power tools. Ear protection is vital in noisy environments to prevent hearing damage. Always check that your safety gear is in good condition and fits properly for optimal protection.

Step-by-Step Guide to Installation

Not only does the installation process require precision, but it also involves the correct tools to guarantee a secure fitting. Here’s a comprehensive breakdown to guide you through each phase.

| Step | Description |

| 1 | Preparing the Plasterboard |

| 2 | Installing the Speed Plug |

Preparing the Plasterboard

Installing the Speed Plug

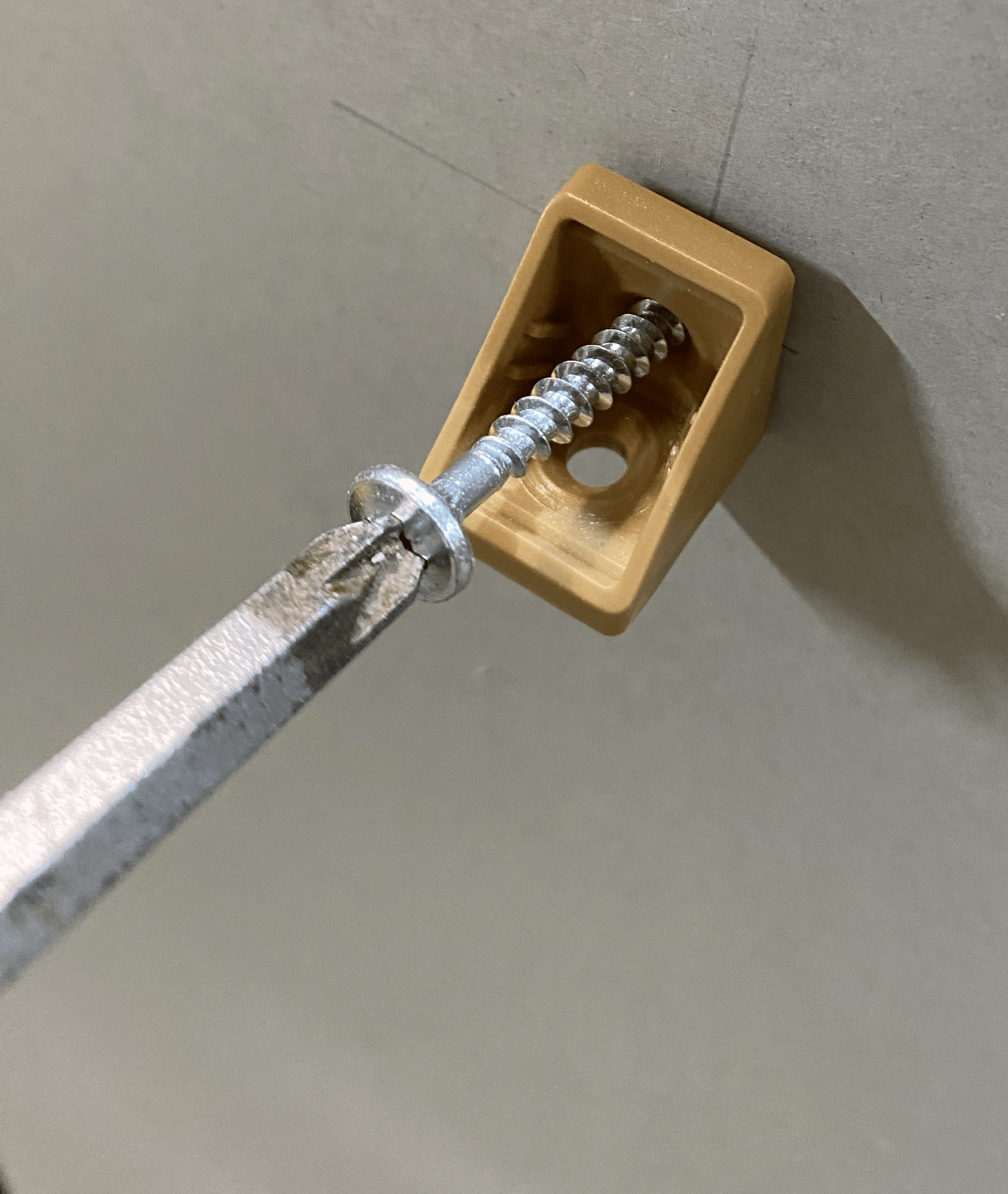

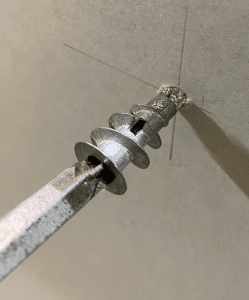

For the installation, you will need to insert the speed plug into the pre-drilled hole, ensuring that it sits flush against the plasterboard. Use a screwdriver to tighten the fixing without overdoing it, as this can damage both the plug and the board.

But be attentive; if you overtighten, you risk cracking the plasterboard or displacing the fixing, leading to an unstable installation. Ensure you feel a solid resistance as you tighten, which indicates a proper fit. If the plug feels loose, you may need to reposition it or consider a larger fixing for added support and stability. By following these guidelines, your installation will be both safe and reliable.

Common Mistakes to Avoid

Unlike the common perception, installing metal speed plug plasterboard fixings is not as straightforward as it seems. Many DIY enthusiasts overlook specific details that can lead to ineffective or unsafe installations. Avoiding these mistakes will not only enhance the durability of your fixings but will also increase the safety of your project.

Incorrect Tool Usage

Behind every successful installation lies the right tools. Using the wrong drill bits or handles can cause damage to the fixings and the surrounding plasterboard, leading to less secure fixtures. Make sure you select tools that are specifically designed for working with metal speed plugs to ensure optimal performance.

Improper Fixing Techniques

Against common belief, simply inserting a speed plug without proper alignment can jeopardise your installation. Ensuring that you properly position and secure your fixings is vital. An incorrect approach may not only compromise the integrity of your fixture but can also result in potential hazards, such as falling objects.

Considering the installation of metal speed plug plasterboard fixings, it’s important to adhere to correct fixing techniques to achieve a secure hold. Always ensure that you drill to the appropriate depth and angle; too shallow may lead to poor stability, while too deep can damage the plasterboard. Always check your fixings are aligned properly before securing them in place, as misalignment can lead to a weak connection that compromises safety. Taking the time to follow precise methods will leave you with a robust installation that stands the test of time.

Maintenance and Troubleshooting

Keep your speed plug fixings in top condition by routinely inspecting and maintaining them. Regular checks can help identify potential issues before they escalate, ensuring your plasterboard remains secure. Look for signs of wear, ensure the plugs are properly anchored, and replace any damaged components promptly to avoid complications.

Inspecting Installed Speed Plugs

Repairing Common Issues

Installed speed plugs can sometimes develop issues that require prompt attention. If you find a plug that has loosened, removing and replacing it with a new one is often necessary. For deeper damage, you may need to fill holes with a suitable filler and allow it to set before reinstallation to ensure a secure fit.

Understanding how to effectively manage repairing common issues not only restores the integrity of your install but keeps your projects safe. Always opt for the correct tools during repairs to avoid causing additional damage. Regularly inspecting and maintaining your fixings ensures they remain effective and safe for use, extending the lifespan of your installations.

Final Words

Following this guide, you will have a better understanding of how to select the appropriate tools for installing metal speed plug plasterboard fixings effectively. By considering the specific requirements of your project and using the right equipment, you can ensure a secure and lasting installation. This knowledge empowers you to tackle your plaster boarding projects with confidence and achieve professional results. Equip yourself wisely, and your efforts will reflect in the quality of your work.

Metal Speed Plug Plasterboard Fixings FAQ

Q: What tools are necessary for installing Metal Speed Plug Plasterboard Fixings?

A: To effectively install Metal Speed Plug Plasterboard Fixings, you will need a few important tools. Firstly, a high-quality drill with a suitable drill bit is required to create the initial hole in the plasterboard. A screwdriver or power driver will be necessary for driving the fixing into place. A tape measure can help ensure accurate placement, while a level ensures that your installation is even. Additionally, safety goggles are recommended to protect your eyes during drilling.

Q: How do I choose the right drill bit for Metal Speed Plug installations?

A: When selecting a drill bit for Metal Speed Plug installations, it is important to choose a bit that matches the diameter of the plugs you are using. Typically, a HSS (high-speed steel) drill bit is suitable for this purpose. The bit should also be appropriate for plasterboard, which is relatively soft compared to other materials. Verify the diameter of your Metal Speed Plugs and select a drill bit that is slightly larger to ensure a snug fit without compromising the material.

Q: Are there any specific techniques for ensuring a secure installation of these fixings?

A: Yes, there are several techniques to ensure a secure installation of Metal Speed Plug Plasterboard Fixings. Firstly, it is advisable to drill straight into the plasterboard to avoid any damage to the surrounding area. When inserting the speed plug, ensure that it is fully expanded against the backside of the plasterboard for maximum grip. Additionally, you should use a tool to apply even pressure when driving in the screw, as over-tightening can lead to damage or a weak fixture. Testing the integrity of the fixing after installation can also help ensure that it can support the intended load.